Latest version of Tebis CADCAM supports interpolation turning

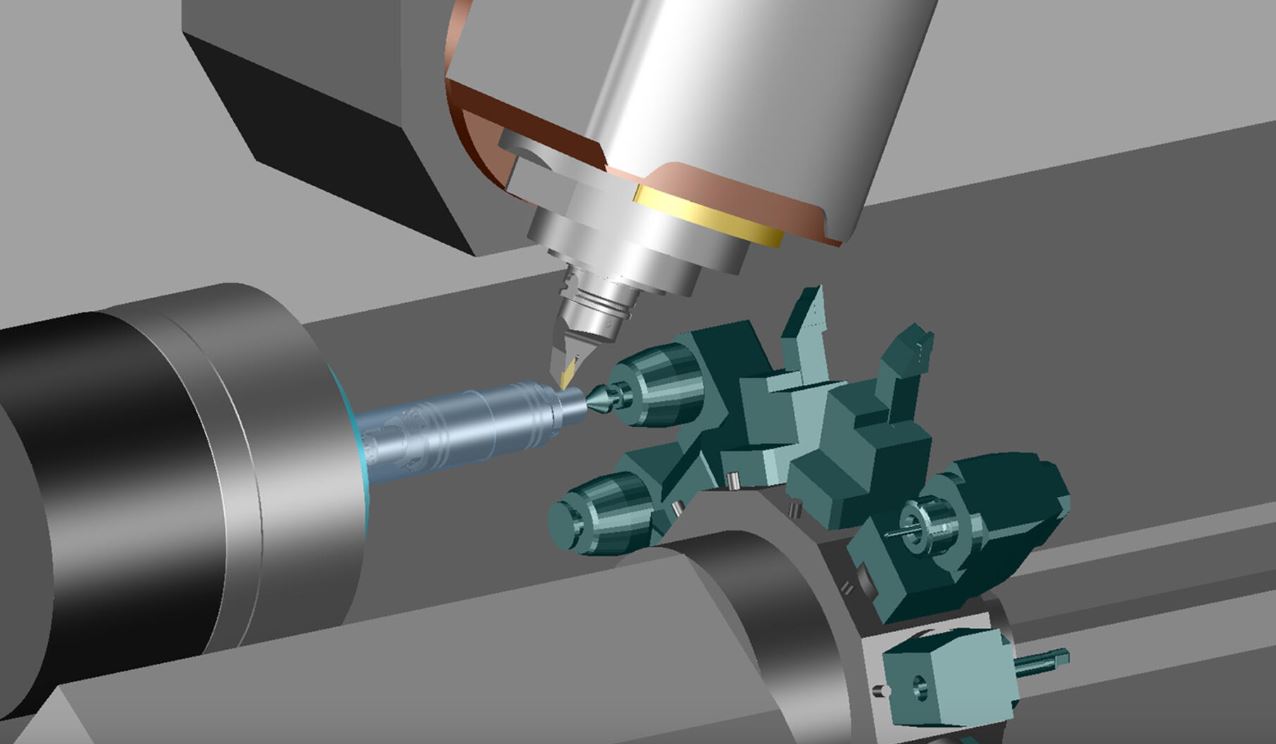

End-to-end automated processes are more important than ever in the manufacturing industry, which is why Tebis Version 4.1 Release 8 CADCAM software is set to enhance flexibility in automation like never before. In addition to turn-milling and mill-turning, Tebis 4.1 Release 8 also supports interpolation turning, enabling the easy and cost-effective production of rotationally symmetrical areas. Combined turn-milling can be used to perform turning and milling operations end-to-end on a single machine without re-clamping. This combined approach is efficient, reduces throughput time and cuts costs.

Christoph Brückner, Key Account Manager at Tebis, explains: “The relatively new manufacturing method of interpolation turning is becoming increasingly popular. It enables turning on all machines that have a position-controlled spindle, including milling machines. This method is especially appropriate for parts with several milled elements and fewer turned elements. Time savings of up to 80% are possible with interpolation turning, because areas that previously had to be milled can now be turned.”

The technique also allows the use of simple turning tools that have a long tool life, rather than high-cost ground milling tools. As the cutter is in continuous contact with the workpiece during interpolation turning, machine shops gain from high surface qualities.

Tebis says its solution is the only one available that’s mastered the next developmental stage of interpolation turning, namely six-axis simultaneous interpolation turning.

“With six-axis simultaneous interpolation turning, even undercut areas can be manufactured easily and efficiently in a single set up,” says Jakub Dittmar, Product Manager at Tebis. “As very short tools can be used in multi-axis turning and the spindle interpolates very smoothly, this type of machining gives us even better surface quality. It’s therefore the ideal technology when precision is foremost.”