ITC Introduces A Smarter Way to Rough Bore

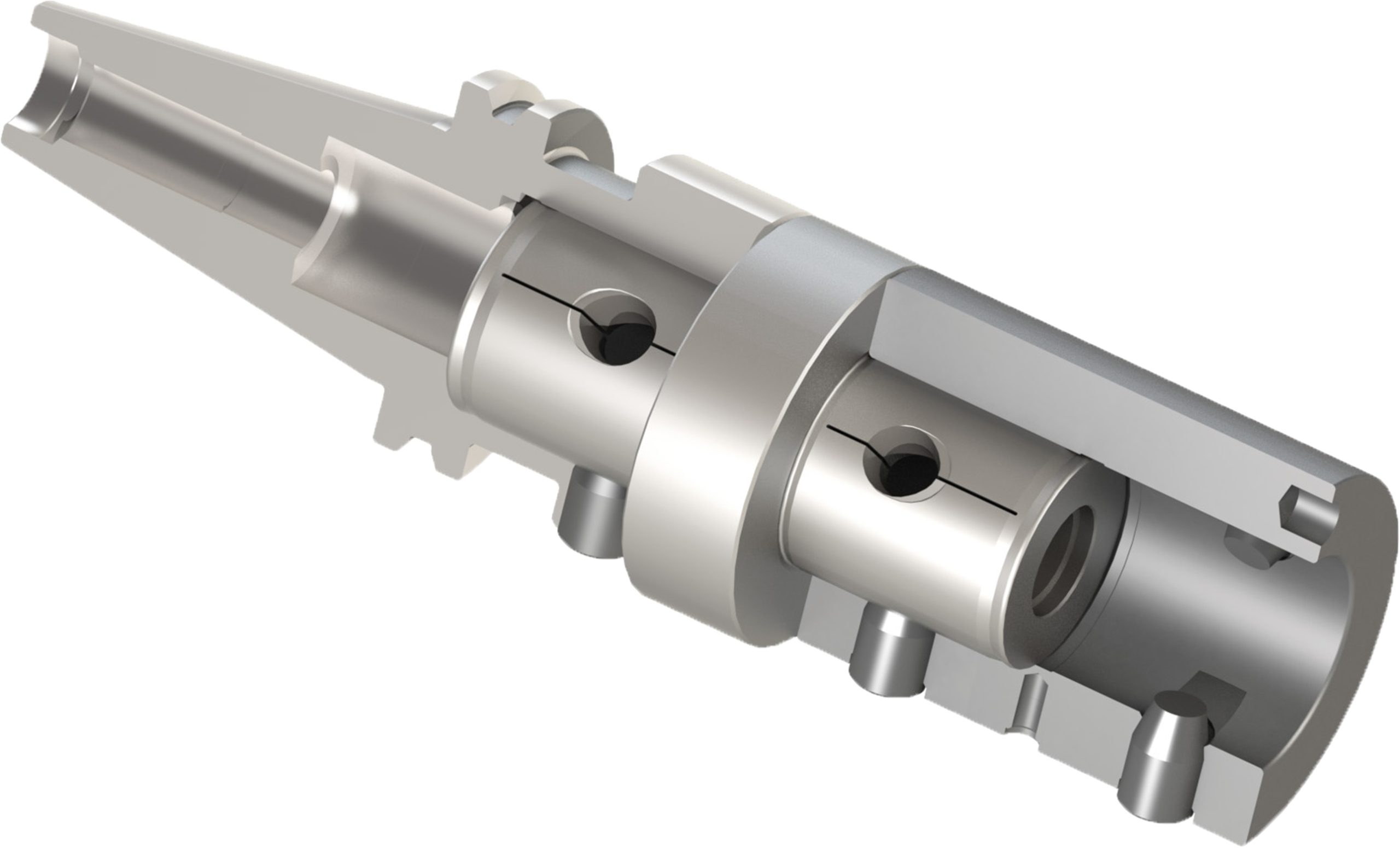

The Smart Damper precision boring series from BIG KAISER is recognised as an industry leader in the world of holemaking. Now, the precision tooling and holemaking specialist has expanded its modular CK family with new head types for rough boring.

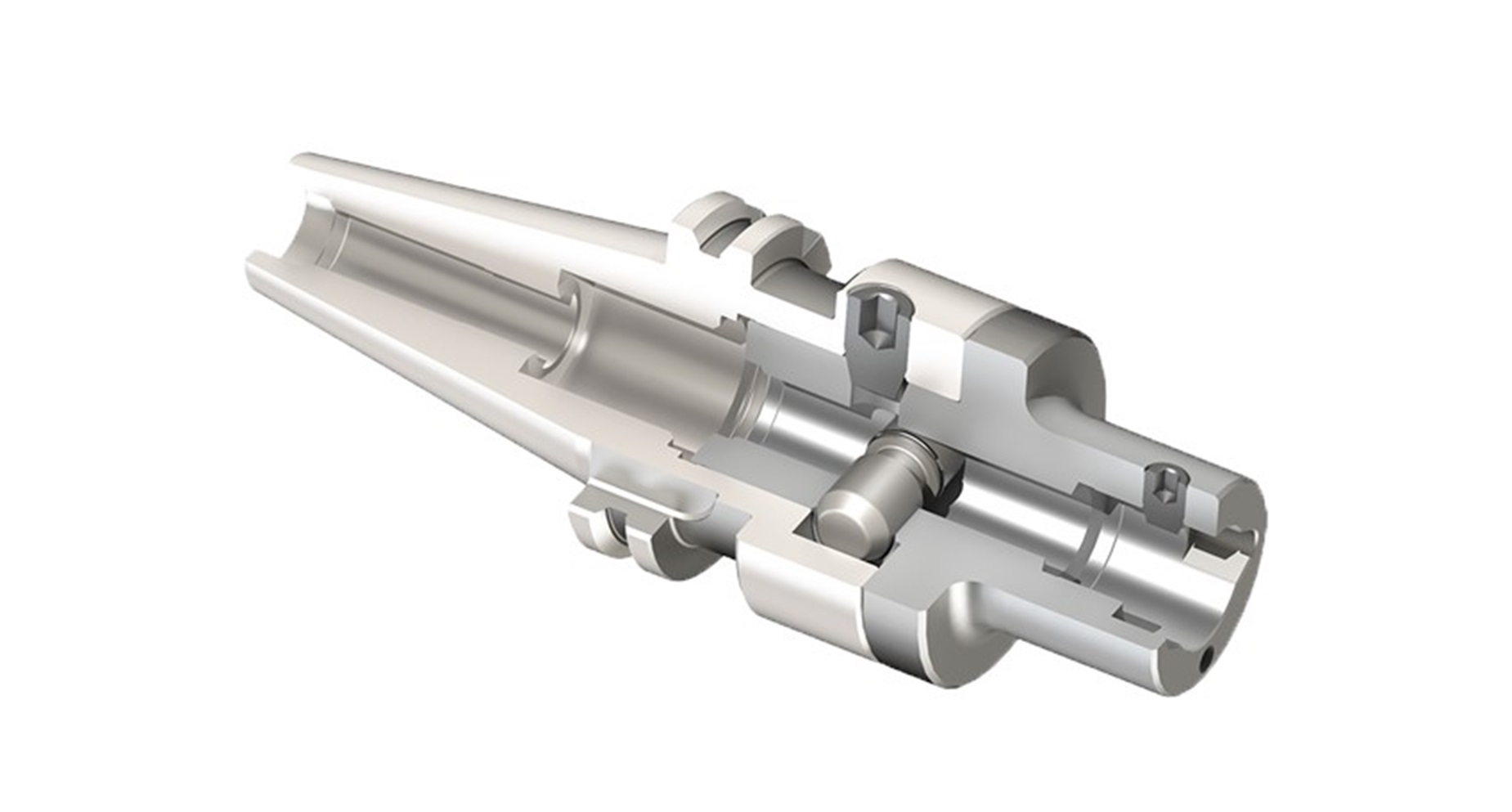

Available in the UK from Industrial Tooling Corporation (ITC), the new Smart Damper SW head for the CK1, CK2 and CKB3 boring tools includes BIG KAISER’s Smart Damper technology. This minimises vibration and eliminates chatter, which is of critical importance when conducting rough boring operations. The exceptional new modular CK system is the world’s most versatile tooling system and when supported by industry experts from Tamworth-based ITC, the performance and results will far exceed that of any other holemaking system.

The new additions to the CK modular precision tool system are also available for the full range of the BIG KAISER SW rough boring family. This makes the SW heads more versatile than ever before. Furthermore, it boosts the already impressive stability of the CK compatible connections with the BIG KAISER CK now found compatible with rough boring heads, fine boring heads, bridge tools as well as many accessories in the BIG KAISER range from ITC.

“The Smart Damper SW Heads offer boring efficiency six times higher with twice the cutting depth and three times the cutting conditions of other rough boring heads. The Smart Damper technology makes boring quieter, more efficient and vibration-free,” said Giampaolo Roccatello, Chief Sales & Marketing Officer for BIG KAISER Europe.

Based on a cylindrical connection with the radial locking screw, the CK system has been continuously improved over the years to adapt to customers’ changing needs and the increases in machine tool performance. Compatibility with existing tools has always been a stringent requirement for newly designed products. As well as interchangeability within the BIG KAISER family, the CK system is also fully compatible with all machine tool interfaces and enables customers to create tool assemblies specific to each machining application. This includes extending tools for machining in deep cavities. The integration of the Smart Damper shortens the distance from the damping mechanism to the cutting edge which creates the source of vibration. This increased damping system within the tool assembly minimises vibration and enables the CK system to achieve better surface finishes and improved metal removal rates whilst also prolonging tool life and enhancing surface finishes. The Smart Damper SW head for the CK1, CK2 and CKB3 is now available and all components are available from ITC. For further information, please contact your local ITC representative.