ITC Cuts Tooling Costs & Cycle Times for Prestigious Subcontractor

Celebrating its 30th year of business, Tml Precision Engineering is a Tier 1 & 2 subcontract manufacturer that invests in the very finest technology to service leading OEMs and supply chains in the aerospace, motorsport, medical and renewable energy sectors. To extend its competitive advantage, the Norwich-based company has been utilising cutting tools from Tamworth-based Industrial Tooling Corporation (ITC).

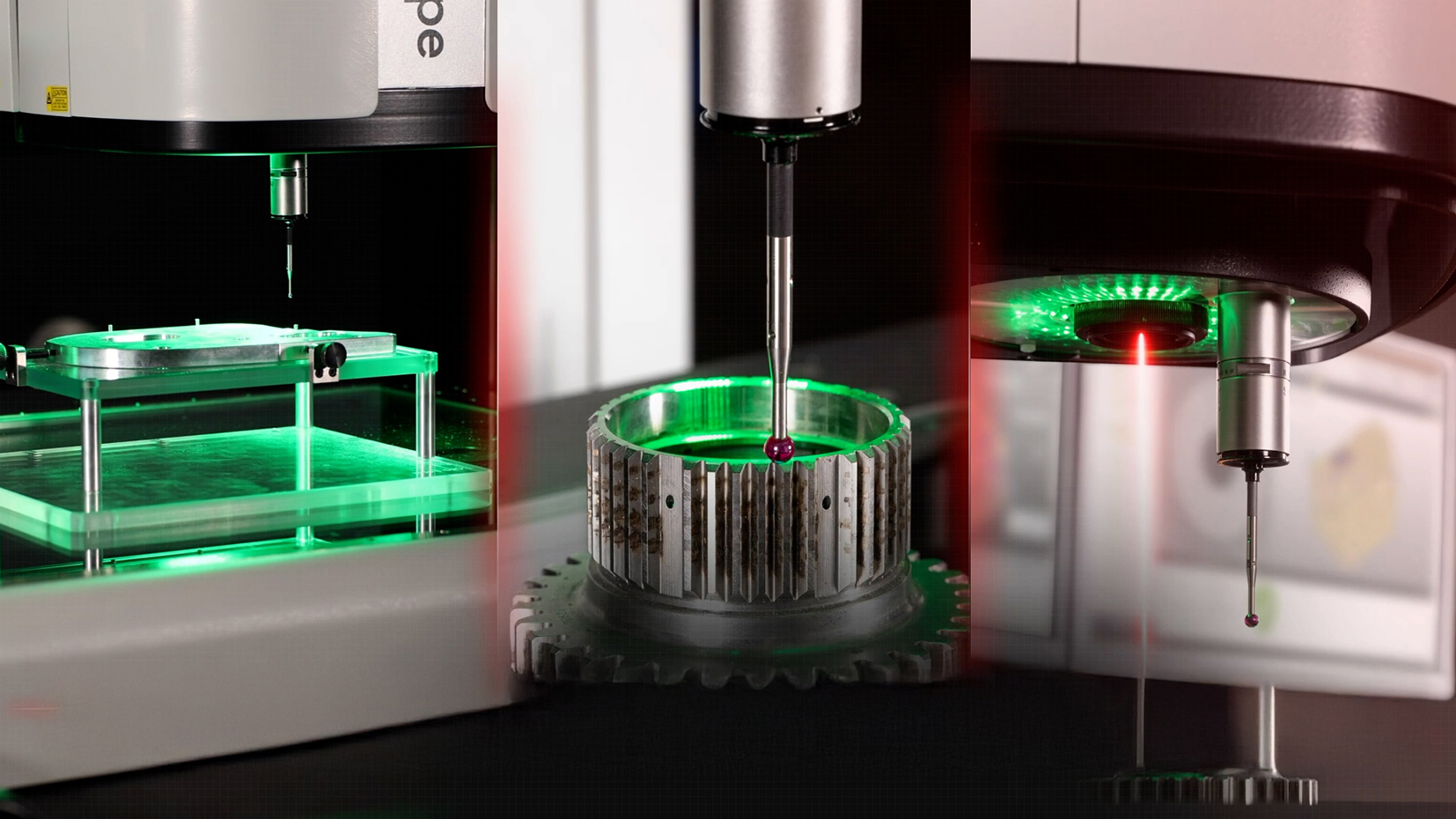

Working to ISO: 9001 and AS: 9100, Tml has invested in the very latest technology with multi-pallet 5-axis machine tools from Matsuura and DMG MORI, mill/turn centres from Mazak and turning centres from Mazak and Nakamura-Tome (ETG). With high-quality machine tools offering extended periods of unmanned machining, Tml was looking to improve its tool life whilst simultaneously reducing cycle times and consequentially its commercial advantage – an initial market review led to ITC being chosen to deliver the results based on service capability and technical support.

Local ITC Technical Engineer Dan Smith called upon the Norfolk manufacturer and initially trialled several ITCs 2041 Series of solid carbide end mills for aluminium machining. Applied to a series of battery system components for a Norfolk-based automotive OEM, the initial trial proved fruitful with productivity rates and tool life both improving. The improved results led to the 2041 Series and other aluminium specific end mills being adopted on the shopfloor at Tml. It also gave the manufacturer confidence in both ITC’s products and the expertise of the technical engineering team to trial the WIDIA range of indexable turning tools. The results were once again impressive.

The WIDIA Victory Series of CNMG and WNMG indexable inserts from ITC for machining steel and stainless were applied to a family of more than 10 different flow regulator and pipe assembly components to undertake rough turning. Machined on one of the company’s Mazak Integrex mill/turn centres, the ITC engineer swapped out the previous inserts and retained ‘like-for-like’ cutting data with the four-edged inserts. The ITC WIDIA Victory turning series yielded a tool life of 16 parts per insert edge compared to the previous four parts per insert edge. This significant tool life saving has proven hugely beneficial for Tml, especially as the pipe assembly parts are high-volume components manufactured throughout the year.

One of the components in the assembly was particularly challenging, as ITC’s Dan Smith recalls: “One part manufactured from stainless steel bar has a seam weld that results in intermittent cutting, which is why tool life was an issue for Tml. However, the performance of the WIDIA Victory turning series massively improved tool life and another benefit was reduced insert changeovers and subsequent cost reductions. To further reduce costs in the mill/turn department, we introduced the latest WIDIA WCE4 Series of solid carbide end mills. Introducing the 3, 4, 6 and 8mm diameter end mills with the variable helix flutes, tool life was improved and the variable helix enhanced surface finishes and reduced vibration on milling operations in the mill/turn centres.”

No Run of the Mill Tools

Following the earlier successes established for aluminium milling and the subsequent introduction of small diameter end mills to the mill/turn machines, ITC had an opportunity to look at other milling projects – the results did not disappoint. An aluminium component that is regularly machined in batches up to circa 100-off required 30mm of metal removal on the face. Previously, Tml was using a 4-flute solid carbide end mill from a rival supplier, which was resulting in poor tool life and surface finishes – this was primarily caused by vibration and poor chip evacuation. Furthermore, with poor surface finishes and excessive noise and vibration, Tml had to use one end mill for rough machining and a second tool for finishing. The ITC engineer rapidly eradicated this with the introduction of a 16mm diameter ITC 4104 Series aluminium roughing tool with chipbreaker. To maximise the rigidity of the set-up, the ITC Technical Engineer introduced a BIG KAISER HMC chuck to complement the end mill.

The combination of the 4104 chipbreaker end mill and the BIG KAISER HMC chuck enabled Tml to take a full flute 30mm depth of cut and run at 10,000rpm with a 1.8mm step over and a feed rate of 7200mm/min. On a batch of 80 parts, the ITC 4104 Series proved to be a more cost-effective tool that subsequently reduced the cycle time by upwards of 20% whilst improving the surface finish substantially – to the point that a secondary finishing tool was not required. The single tool machined the entire batch of 80 parts and saved more time with no additional tool changeover or cost implications.

The combined benefits of the respective tools have been significant after just 6 months of working with ITC. However, the most impressive result to date has been achieved on the latest part that ITC has been introduced to. A large EN8 component for the entertainment industry requires 77% material removal – taking the part from 9kg down to just 2kg. On the rough facing of the component, Tml was previously applying a face mill, which was yielding a roughing cycle time of 1.5 hours. The ITC engineer swapped out the face mill for an ITC 16mm diameter 6054-16 Series 6-flute end mill with a chipbreaker. With a 50mm flute length, the 6054-16 Series cut at a full 50mm flute depth with a 0.8mm stepover and a cutting speed of 4777rpm. Cutting with such aggressive material removal rates on a Matsuura MAM72, the stability of the end mill was further enhanced by a BIG KAISER HMC chuck that demonstrates complete face and taper contact for maximum rigidity. The combination of the BIG KAISER chuck and the 6054-16 Series end mill cut the roughing cycle from 1.5 hours to just 15 minutes – and with a quantity of 60 parts, the cycle time reduction is equal to more than 3 days of machining.

Most engineers would be happy to deliver such a substantial saving for a customer, but not the engineers at ITC. On the same part, ITC’s Dan identified an opportunity to remove a 90 degree indexable end mill that was being used for interpolating bores. Replacing the indexable tool with ITCs solid carbide 4081 Series of 4-flute end mills with AlTiN coating, another 45 minutes were shaved from the cycle time, taking the complete cycle time from 3 hours to just over 1 hour.

Concluding on the working relationship with Tml, Dan says: “We have worked with TML for little over 6 months, but the results have been exceptional. This is a credit to the receptiveness of Tml to adopt new techniques to improve their cycle times, reduce tooling costs and consumption. However, such significant benefits would not be possible with other tooling manufacturers. ITC can manufacture and provide high-quality UK manufactured solid carbide tooling, industry-leading indexable tools from WIDIA along with the world’s leading toolholding systems from BIG KAISER. The combination certainly gives our customers an advantage, as Tml is currently witnessing.”