ISCAR Explores – Advanced Solutions for Heat Exchanger Manufacturing

Heat exchangers are the quiet workhorses of modern industry. From powering vehicles and generating electricity to ensuring the safety of aircraft systems, they play a central role in thermal management. These components transfer heat with remarkable efficiency, but creating them is anything but simple. Large dimensions, intricate geometry and difficult-to-machine materials make their manufacture one of engineering’s greatest challenges.

ISCAR explores these challenges with a portfolio of precision tooling that covers every stage of production. From robust roughing tools to finishing systems that deliver micron-level accuracy, ISCAR provides manufacturers with the capability to turn complexity into opportunity.

Setting the Stage: Tube Sheet Preparation

The tube sheet forms the foundation of most heat exchangers, and its preparation is critical. Face milling is the first step, and the surface quality achieved here influences every operation that follows.

ISCAR approaches this task with a family of face mills designed to combine toughness with finesse. For high-feed milling, the FFQ4 SOMT 0904 insert provides four effective cutting edges that keep productivity high while maintaining surface integrity. The H1200 HXCU 0606, with its double-sided hexagonal design, offers twelve edges, extending tool life and reducing changeovers. For more general applications, the IQ845 stands out as a versatile performer with eight edges and reliable stability. Meanwhile, the octagonal ONMU and ONHU inserts, boasting sixteen helical edges, provide an economical option that delivers excellent finish quality.

Each solution is crafted to give manufacturers confidence that their tube sheet preparation will not only meet specifications but also enhance the efficiency of subsequent processes.

Mastering the Art of Heavy-Duty Turning

Turning operations in heat exchanger production are notorious for their intensity. Machinists often contend with stainless steels and other stubborn materials, and the cuts themselves can be deep and unforgiving. Tool stability, chip control and accuracy are non-negotiable.

ISCAR’s turning platforms embrace these challenges. The DOVE-IQ system, for instance, is engineered for heavy-duty steel turning, its double-sided rhombic inserts built to endure high loads without losing edge integrity. For rough machining stainless and low-carbon steels, the CNMG-R3M insert has become a trusted choice, balancing strength with precision. When it comes to aggressive roughing, round RCMX inserts provide a strong cutting edge that keeps performance steady under pressure. At the upper end of material removal, tangential LOMX inserts handle depths of cut up to 35 millimetres on steel, delivering both productivity and dimensional accuracy.

The result is a turning suite that allows manufacturers to tackle heavy-duty applications with confidence, transforming what might seem like a limitation into an opportunity for efficiency.

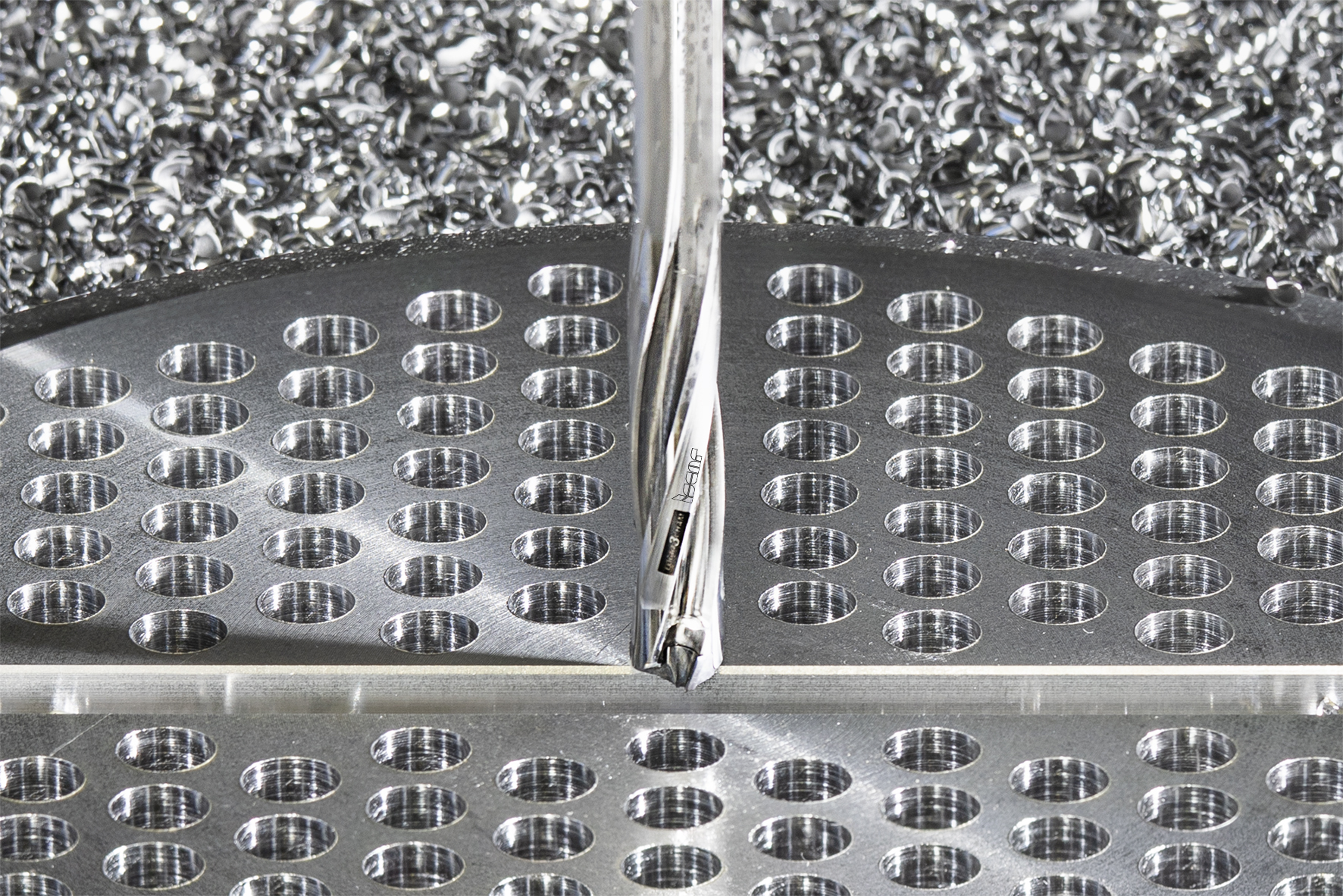

Redefining Precision Drilling

Few operations test accuracy more stringently than drilling tube sheets and baffles. Hundreds of holes must be produced with absolute repeatability, and every minute of downtime costs money.

The SUMOCHAM line is ISCAR’s answer. This modular system employs exchangeable heads and a quick-change clamping mechanism to minimise set-up time while maintaining consistent accuracy. With diameters ranging from 4 to 32.9 millimetres, SUMOCHAM offers flexibility across material groups. Its self-centring chisel design eliminates the need for pilot holes up to twelve times the diameter, while polished flutes ensure smooth chip evacuation and stable operation.

For those seeking to push productivity even further, the QUICK-3-CHAM drill offers a breakthrough. Its three-flute design cuts cycle times by up to 50 per cent compared with traditional two-flute tools. Patented concave cutting edges and wavy geometries produce chips that are easy to evacuate, while wear-resistant features such as corner chamfers extend tool life. Stability, speed and precision combine to deliver a new level of drilling performance.

Going Deeper: The TRI-DEEP and ISCAR-DEEP-DRILL Lines

Some heat exchangers demand drilling depths that challenge even the most advanced tools. ISCAR explores this frontier with the TRI-DEEP and ISCAR-DEEP-DRILL ranges.

The TRI-DEEP platform provides flexibility through gun drills and single- and double-tube systems, with diameters spanning from just under eight millimetres to 40 millimetres. For larger requirements, the ISCAR-DEEP-DRILL line expands the range dramatically, offering tools up to 294 millimetres in diameter. Cartridge-equipped designs enable diameter expansion without sacrificing stability, making it possible to tackle extreme depths with confidence.

These solutions allow manufacturers to produce deep, precise holes that were once considered beyond reach, enabling new possibilities in heat exchanger design.

Perfecting the Finishing Touch

After the heavy lifting of roughing and drilling, the finishing stages of grooving, chamfering and reaming bring everything together. These operations may appear minor, but they guarantee sealing integrity, reliable performance and long service life.

For grooving, ISCAR’s MULTI-MASTER system provides chatter-free cutting, producing smooth surfaces with minimal burr formation. Its modular design allows easy adaptation to different diameters, ensuring flexibility as well as accuracy. Chamfering heads with up to six flutes and point angles of 45 or 60 degrees deliver fast, crisp edge finishes, speeding up the process without compromising quality.

When it comes to reaming, the BAYO-T-REAM system sets the standard. With diameters from 11.5 to 32 millimetres and repeatability within three microns, it delivers the tight tolerances that sealing surfaces demand. Internal coolant flow enhances chip control, improving both tool life and surface finish.

Tackling the Complex with Specialised Solutions

Not every challenge in heat exchanger manufacturing can be solved with conventional methods. Trepanning, core drilling and modular head applications often require specialised tools.

ISCAR’s TREPAN-DRILL offers an elegant solution for core drilling by retaining the removed material, reducing waste and allowing it to be reused. The CHAM-IQ-DRILL pushes tolerance boundaries, achieving accuracy levels that often remove the need for secondary finishing. For semi-finishing and rough operations under demanding conditions, the ISCAR-DR-DH heads provide robust performance, while the COMBI-CHAM range enables accurate deep drilling without the need for pilot holes.

These tools represent ISCAR’s commitment to exploring every corner of the machining landscape, ensuring that even the most complex requirements can be met with confidence.

Precision without Compromise

From the first milling pass on a tube sheet to the last micron of a reamed hole, ISCAR explores the full journey of heat exchanger manufacturing. Each tool in the company’s portfolio reflects a blend of innovation, durability and precision, helping manufacturers not only meet industry standards but often surpass them.

In a sector where efficiency, reliability and accuracy are essential, ISCAR’s solutions provide the assurance that there is no compromise at any stage. Heat exchanger machining is one of engineering’s greatest challenges. With ISCAR’s expertise and tooling, it becomes an opportunity to achieve more than ever before.