Investment in Starrag machines helps productivity take-off at aerospace manufacturer

By investing in machine tools from Starrag, Missouri, US-based Seyer Industries is today a major manufacturer of critical aerospace components, evolving a long way from its origins in a farmer’s garage back in 1957.

Self-taught tinkerer and inventor Lou Seyer made enough money in the 1950s from his ‘Easy Egg Cracker’ invention for boiled eggs to partner with Harold Buckner and purchase machinery from a failing business. In the early 1980s, the company started manufacturing support equipment for the military and began working on McDonnell Douglas Aircraft. Success has been exponential ever since.

Today, Seyer is a third-generation family-owned aerospace company that offers four primary product groups and operates from a 210,000 sq ft facility. Its activities include supporting customers in the commercial aerospace, military aerospace, military support equipment and maritime industries. The company’s ongoging investment strategy is proving so successful, the AS9100D, ISO9001, ITAR-registered and NADCAP-certified company has grown 20% per annum for the past five years.

One impressive element of the company’s investment strategy is its 1.8 MW solar panel system that generates over 30% of Seyer’s electricity needs. Covering three of its four buildings, the only reason the 4,216-panel installation does not qualify as Missouri’s largest commercial solar-powered system is because it is spread over three buildings. Even so, Seyer’s commitment to minimising its carbon footprint is admirable and exceeds the largest in-state installation of 4,085 panels on top of a globally renowned Swedish furniture store.

Discussing the company’s activities, Mark Seyer, Director of Operations at Seyer Industries, says: “Our mission is to be the best-in-class supplier of complex aerospace products. Seyer specialises in hard metal machining and large bills of material. We offer great value through vertical integration and a high degree of collaboration with customers. As part of efforts to take complex problems off the hands of our customers we’ve built our process offering to support large, hard-material machined parts and assemblies. As price and lead time are everything in aerospace, adding the capability of large-capacity machining will help Seyer offer a complete partner solution for more of our customers. To achieve this, we decided to invest in machine tools from Starrag.”

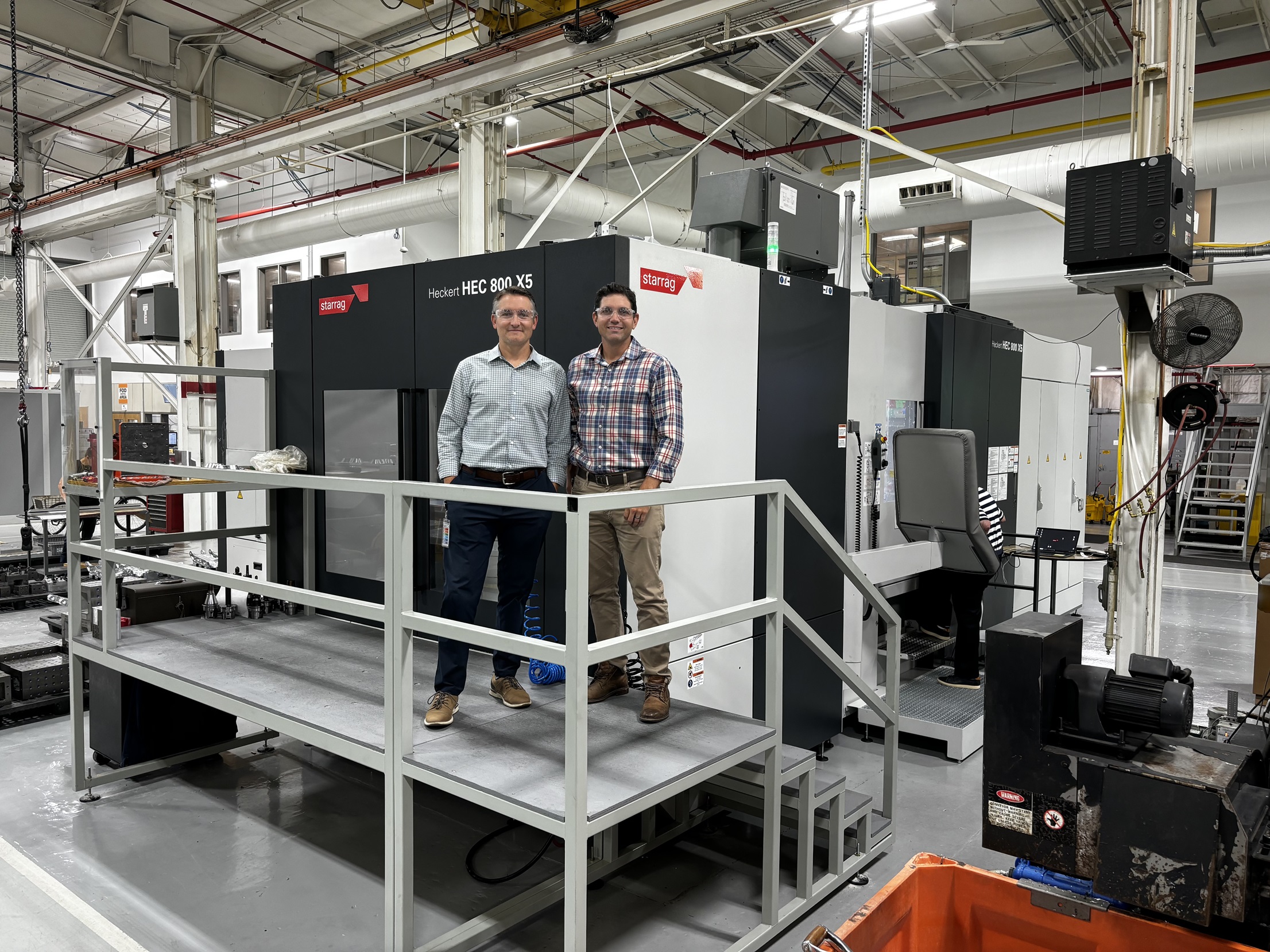

Working with most of the world’s aerospace primes and their supply chains, Starrag was the obvious choice for Seyer when it won a contract to manufacture defence industry components. With the project requiring the machining of hard metal parts with dimensions of 1,000 x 300 x 300 mm, the billets had to undergo high material removal machining with impeccable precision and surface finishes. The solution was the Starrag Heckert 800 X5.

The Heckert 800 X5 is a five-axis horizontal machine with a trunnion design that delivers both the precision and rigidity required for Seyer to machine the hardest materials at high material removal rates. This is complemented by a 12,500 rpm spindle specifically selected by Seyer to deliver the torque needed for milling hard aerospace-grade alloys. The spindle also offers the higher speed and horsepower necessary to machine softer materials. The pallet changer allows the operator to set up the next part while the machine is in operation. This capability ensures the spindle is always turning, maximising efficiency, output and minimising set-up times. Set-ups and downtime see further reduction thanks to a 180-position tool changer with temperature-controlled coolant, part probing and laser tool probing. These features enable the new Heckert 800 X5 to run for prolonged periods unmanned while providing maximum output with minimal operator intervention.

Commenting upon the relationship with Starrag, Seyer says: “Starrag comes with a great reputation of providing robust machines with top-notch precision. There’s no room for error with the parts we plan to produce on this machine. That’s why we’ve partnered with Starrag. The build quality, rigidity, stability, performance and precision – backed by Starrag’s support network and technical experts – will ensure we attain impeccable quality levels to exceed our customer expectations.”

He continues: “During the sales journey, Starrag sold itself as an ‘engineering company that manufactures machines’. From contract negotiations through the build cycle of the machine, Starrag has come through on their word and they’ve been fantastic to work with, especially regarding the customisation and design elements of the machine.”

Looking to the next step, the company has already committed to machine number two: a six-axis Starrag STC1800-170 set to arrive in autumn 2025. The machine will manufacture large titanium structural parts for the defence industry and, with its 3.3 x 2 x 2 m capacity, the Starrag STC1800-170 will add both capacity and capability to Seyer’s competitive advantage.

“We expect this machine to process stainless steel, titanium and Inconel structural aerospace components, typically in smaller batch sizes in the realm of 2 to 10 pieces,” he says.

To manufacture these challenging materials, Seyer has specified its STC1800-170 with a 53 kW spindle that boasts over 1300 Nm of torque at 100% duty cycle with a spindle speed of 5,600 rpm. The power of the HSK-A100-24 spindle enables this machine to deliver material removal rates of beyond 800 cm3/min on titanium. The quality and stability of this spindle are so assured, Starrag provides a five-year warranty that is extendable to a decade.

Optimising flexible manufacturing, the six-axis STC1800-170 features a tilt station that allows the machining of parts in both the horizontal and vertical orientation. Additional standard features include the automatic calibration and verification of machine kinematics, temperature-controlled coolant and the generation of probing reports. Furthermore, with Seyer recognising that hard metals require a large number of cutting tools, the manufacturer has chosen to equip its new STC with a 450-position automatic tool changer with RFID system and tool verification laser.

Highlighting the attributes of the Starrag brand and how it fits with the demands that the company places on its machines, Seyer says: “Precision and repeatability are key components that we focus on when selecting a machine. Depending on the gap we’re trying to fill, spindle selection, envelope size, tool capacity and automation abilities can be other areas of interest.”

He adds: “With automation becoming more and more the norm, high tool capacity and data gathering are a must. Offline programming, set up and quick changeovers are also necessary to ensure full machine utilisation. Intuitive and maintainable controls that allow our skilled machinists, programmers and engineers to get optimal performance from the machine across diverse products are also essential. In summary, we need a highly flexible solution that is intuitive to operate with the highest degree of accuracy and repeatability.”