How Can the Machine Building Industry Profit from On-Demand Manufacturing in 2024

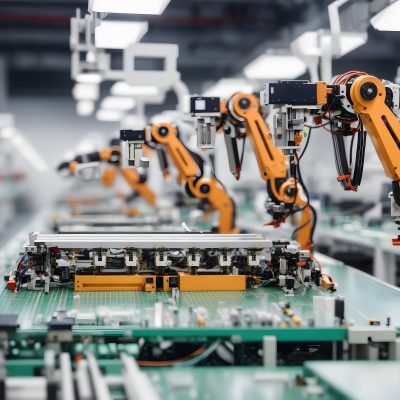

In the era of digital transformation, companies have to evolve and adapt, and this shift is impacting almost every industry. This trend demands new concepts for machinery to advance, which in turn imposes new demands on machine building. As Industry 4.0 and digitisation advances in industries like Industrial Automation and Robotics, many digital tools and platforms are also becoming available to help machine building advance, one of which is known as on-demand manufacture.

What is on-demand manufacture

On-demand manufacturing brings about a revolutionary change in how engineers and buyers can interact with suppliers, particularly in the context of custom fabricated machine building. The rise of cloud-based technologies and platforms has digitised manufacturing, and in so doing, offers machinists a resilient supply chain online, where they can gain access to a massive manufacturing network that offers unlimited capacities to produce high quality industrial parts. An example of a leading on-demand manufacturing platform is Xometry – a free-to-use online platform for part instant quoting and sourcing.

Become a full-service solutions provider

Machine building is a complex process involving tasks like welding and assembling hardware, such as structural components, movement-controlling mechanisms, and control components. Whether engaged in developing machinery for internal purposes or offering services to external clients, choosing an on-demand manufacturer provides a strategic advantage.

By selecting an on-demand manufacturer like Xometry, machine builders gain access to an advanced array of manufacturing technologies, spanning from CNC machining, sheet metal fabrication, injection moulding, and industrial 3D printing. This diverse toolkit empowers machine builders to produce a wide variety of machinery parts, offering flexibility and customisation around their business goals or those of their clients.

Xometry’s extensive capabilities, ranging from prototyping to large-scale production (producing one to one million parts), highlight the scalability and adaptability inherent in on-demand manufacturing. This flexibility allows machine builders to efficiently meet the demands of diverse projects from a single custom machine to a serial parts for high volume machinery. The one-stop-shop solution provided by platforms like Xometry streamlines the entire process, enabling machine builders to navigate project complexities seamlessly.

Increase productivity

Instead of the time-consuming process of qualifying multiple suppliers for a single project, on-demand manufacture can save you up to 60% of project time by providing a resilient, vetted, and consolidated supply chain all in one centralised platform.

The machine building process encompasses design and development, modelling for testing and validation, and finally, machinery construction. Machinists can seamlessly integrate on-demand manufacturing at each stage of their machine building projects:

● Design and Develop: Upload your part designs onto an online quoting platform to receive instant pricing along with Design for Manufacturability (DFM) feedback. This feature allows you to estimate machine building costs and make necessary adjustments for enhanced manufacturability.

● Modelling for Testing and Validation: Leverage a diverse set of manufacturing technologies offered by on-demand platforms to create prototypes and test pieces for validation and customer approvals. Industrial 3D printing, for instance, opens avenues for machinists to explore innovative and complex part manufacturing, facilitating the visualisation of ideas.

● Machinery Construction: On-demand manufacturing platforms go beyond mere production, offering additional services to streamline projects, ranging from Non-Disclosure Agreements (NDA) to comprehensive quality inspection reports (Standard, FAIR, CMM). For those focusing on high-volume machinery production, the on-demand manufacturing model provides the flexibility to produce series parts precisely when needed, thereby reducing inventory costs for your business.

By integrating on-demand manufacturing at every step, machine builders can not only save time and resources but also benefit from a streamlined, comprehensive solution that enhances overall productivity.

High quality equals reliability

Manufacturing highly intricate machines is a challenging endeavour. Behind the scenes of an on-demand manufacturing platform, there exists a dedicated in-house team comprising applications engineers, key account managers, and production specialists. Take Xometry, for instance, a platform that boasts ISO 9001:2015 certification and houses a quality assurance lab. Within this facility, a team of professionally-trained quality engineers continuously refines the quality control process, ensuring peace of mind regarding part quality for every order.

Xometry’s commitment to precision extends to working with both custom and general tolerances. For CNC machining and sheet metal fabrication, they adhere to standards such as ISO 2768 (fine, medium) and ISO 286 (Grades 8, 7, 6). In the realm of formative manufacturing technologies, compliance with DIN 16742 and ISO 8062 is ensured. Additionally, for 3D printing, standard industrial tolerances are maintained.

This meticulous approach to quality control and adherence to industry standards underscores the on-demand manufacturing platform’s dedication to delivering not just highly complex machines but doing so with an unwavering commitment to excellence and precision. Collaborating with such platforms provides the assurance of consistently high-quality components in the creation of sophisticated machinery.

Meet the demands of customisation

Single-unit production focuses on crafting unique products tailored to specific customer requirements. Leveraging modular design principles allows for the efficient manufacturing of small series, leading to significant cost reductions. This approach aligns with the evolving preferences of customers who are increasingly seeking tailored solutions rather than mass-produced items.

In response to this shift in demand, machine builders are recognising the benefits of engaging with on-demand manufacturers as a singular source. This strategic partnership enables machine builders to expedite the configuration of products while effectively managing the costs associated with customisation. On-demand manufacturing proves particularly advantageous when there is a need for high-quality customised parts within a short timeframe or when sourcing specific components from alternative suppliers is either impractical or cost-prohibitive.

In essence, the adaptability and customisation options offered by on-demand manufacturing cater to the changing expectations of customers in the machinery industry. It positions machine builders to provide complete solutions precisely aligned with the unique objectives of each machine building project, fostering efficiency and cost-effectiveness in the production process.

Advance your machine building

In conclusion, on-demand manufacturing serves as a driving force for advancement within the machine building sector. By harnessing a diverse array of manufacturing technologies through a unified platform, machine builders can not only elevate their capabilities but also provide bespoke solutions.

As we look forward into 2024, the ongoing digitalisation of machine building paves the way for more flexible and modular machines, characterised by adaptable software at their core. On-demand manufacturing emerges as a key enabler, empowering machine builders to meet the growing demand for complete and customised solutions from customers. Recognising and seizing the opportunities offered by on-demand manufacturing allows machinists to unlock capacity, drive innovation, and expand their service offerings, ensuring a promising future in the dynamic realm of machine building.