Horn introduces modular milling system

Cutting tool manufacturer Horn has introduced a modular, interchangeable-head milling system, the DG range, designed to deliver micron-level precision, faster changeovers and improved sustainability in machining operations.

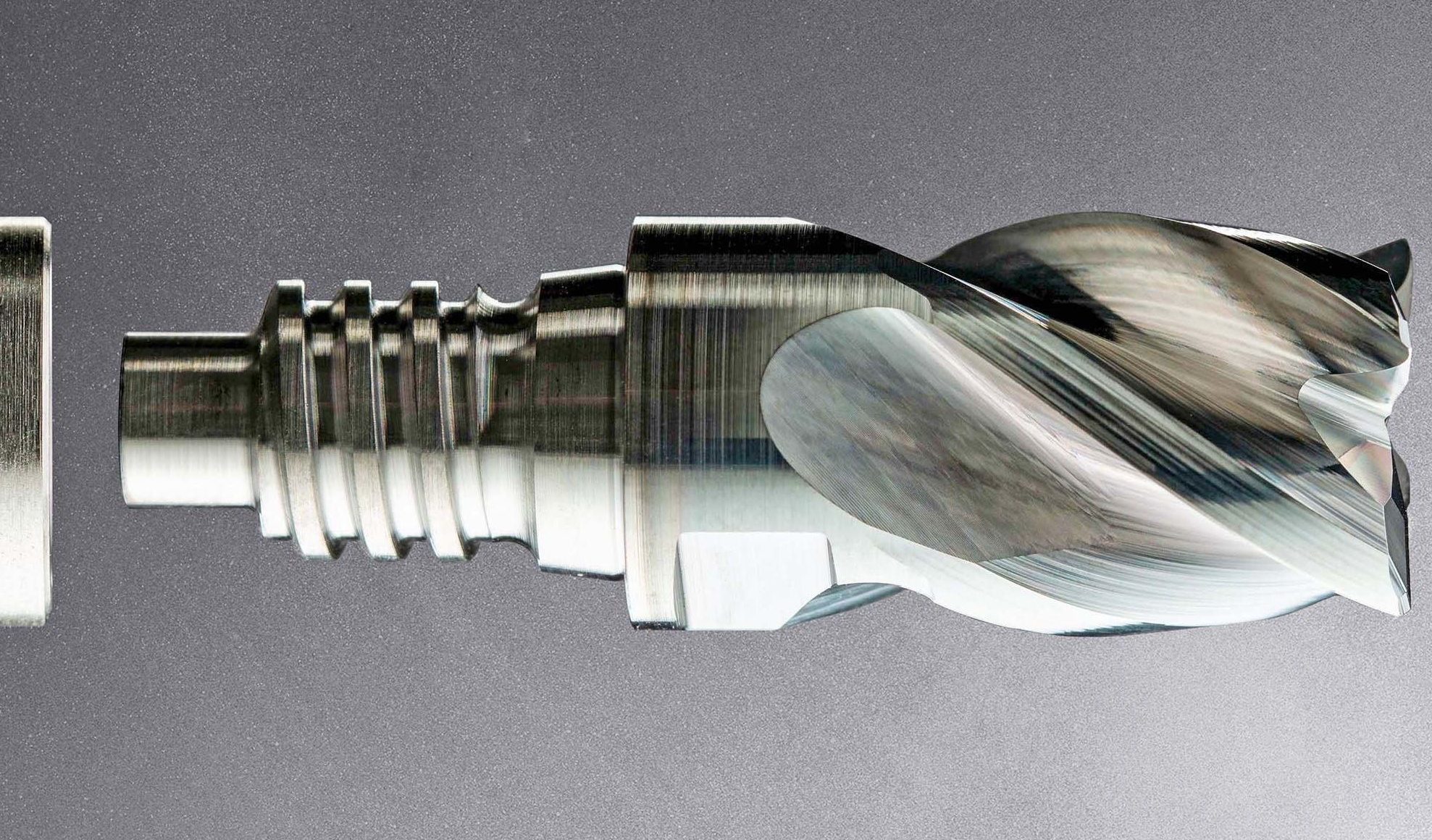

The DG system features a robust interface between the solid-carbide monobloc cutting head and the shank, which is available in either solid carbide or steel and includes an internal coolant supply. Its design incorporates a guide pin, a trapezoidal thread and a face-and-taper contact, ensuring high repeatability and stability while reducing manufacturing and set-up costs.

Horn’s modular approach allows users to switch quickly between standard or custom cutting heads, helping to minimise downtime and increase flexibility. Standard cutting diameters include 10, 12, 16, 20 and 25 mm, with cutting edge lengths of either 0.5xD 1xD.

Horn offers the cutting heads in a new carbide grade, RC4P, which is engineered for productive and economical machining of material groups P (steels) and K (cast irons).