Hill Helicopter’s quality ‘takes-off’

Given the extremely competitive environment global aerospace manufacturers operate within, as well as ensuring the precision capabilities of their quality control equipment, the speed and operational efficiency of the sector’s inspection aids are becoming ever more important.

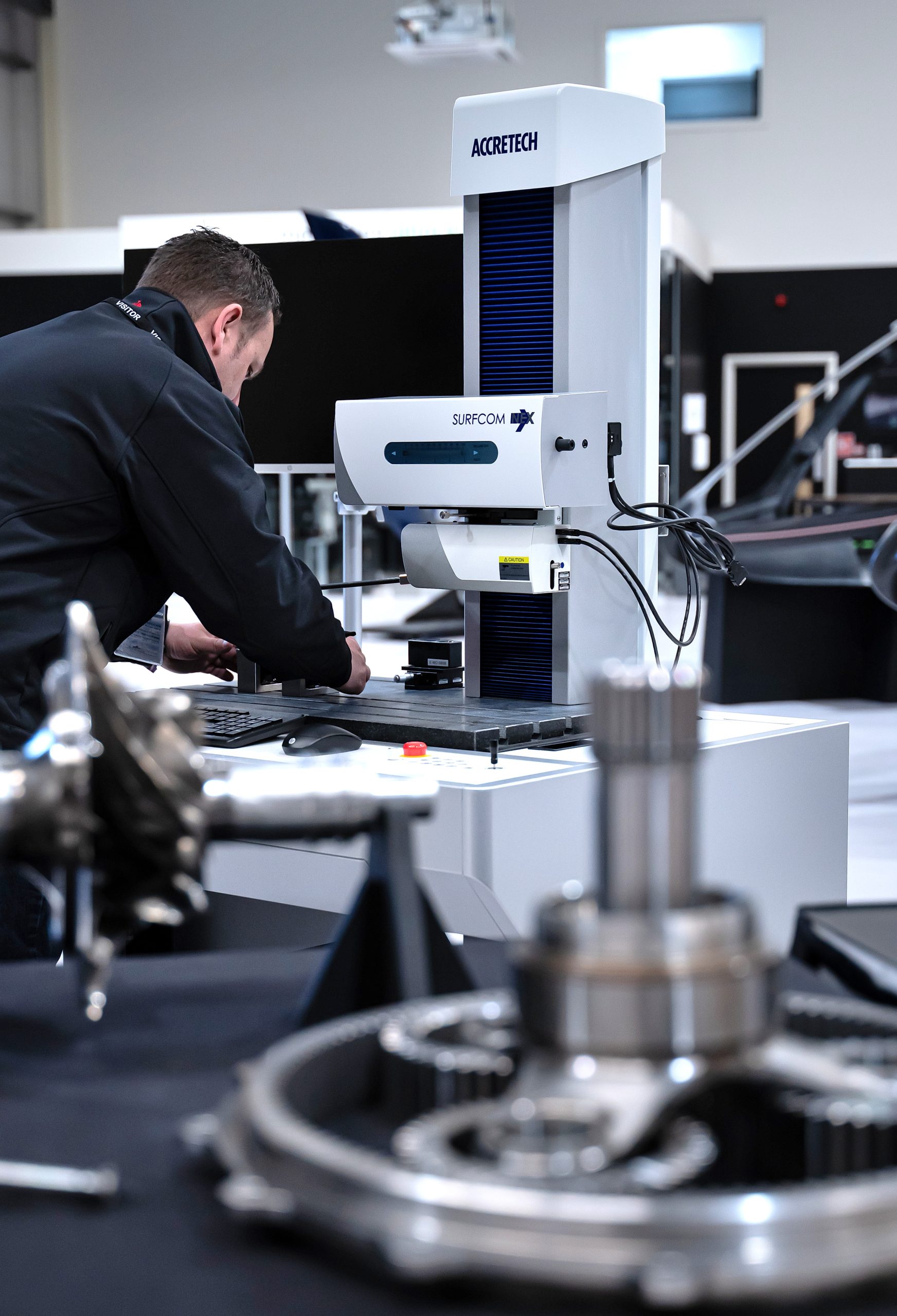

The recent installation of an ACCRETECH SURFCOM NEX surface and contour measuring machine at the premises of Hill Helicopters illustrates the advantages aerospace manufacturers gain when they are able to achieve rapid, high-precision inspection results.

Staffordshire based Hill Helicopters has pioneered a reimagined approach to delivering and supporting safe, exciting luxury private aircraft ownership at an affordable price. The company call this approach General Aviation 2.0. General Aviation 2.0 (GA2.0) extends far beyond the aircraft. It represents an end-to-end ownership experience delivering the aircraft customers have always wanted and combining it with all the support needed to get the best out of private aviation.

Dr Jason Hill, founder and CEO of Hill Helicopters recently unveiled the HX50, a new UK-built, five-seat, turbine-powered helicopter concept. To enable the extremely efficient, high-precision surface and contour inspection of its in-house manufactured components Hill Helicopters recently purchased a SURFCOM NEX 240 DX-13 from ACCRETECH UK.

Explaining the reason for the recently installed machine, Mark Webb, Lead Production Engineer at Hill Helicopters said “Hill Helicopter literature describes the HX50 as delivering of a whole new experience in safety, performance, adventure, comfort and elegance. It isn’t a coincident that ‘safety’ comes first on this list of attributes. To ensure the highest safety standards we oversee a rigorous company-wide quality regime. In addition to employing skilled quality personnel, we invest in the best available inspection equipment.

“The latest addition to our impressive list of inspection aids is our advanced SURFCOM NEX 240 DX-13. After searching for a high-precision, rapid-acting surface and contour measuring instrument we concluded that the advanced ACCRETECH machine best met our demanding accuracy and efficiency standards. In addition to the performance of the instrument, ACCRETECH’s reputation for producing high-quality machines, and for providing excellent levels of customer service, were major factors in our decision.

“During the development and testing of our components our new ACCRETECH machine will be used by our skilled machinists and our production and quality engineers. Then, when we move into full production, we plan to purchase further SURFCOM NEX machines for use on our shopfloor. Given the SURFCOM NEX’s ability to provide high-precision surface and contour measuring results within production environments, it will be ideal for inspecting components throughout our production runs and for generating and archiving FAIRs (first article inspection reports).

“As each of our helicopters have 38 different high-precision bearings, our SURFCOM NEX machines will be used to inspect the critical surface and contour specifications of all of our manufactured bearings. In addition, they will be used on all other relevant in-house produced components. The impressive operational speed and ease of use of our first SURFCOM NEX and that of our planned additional models means that they will be able to keep pace with our high-precision surface and contour inspection needs as our production volumes continue to grow.”

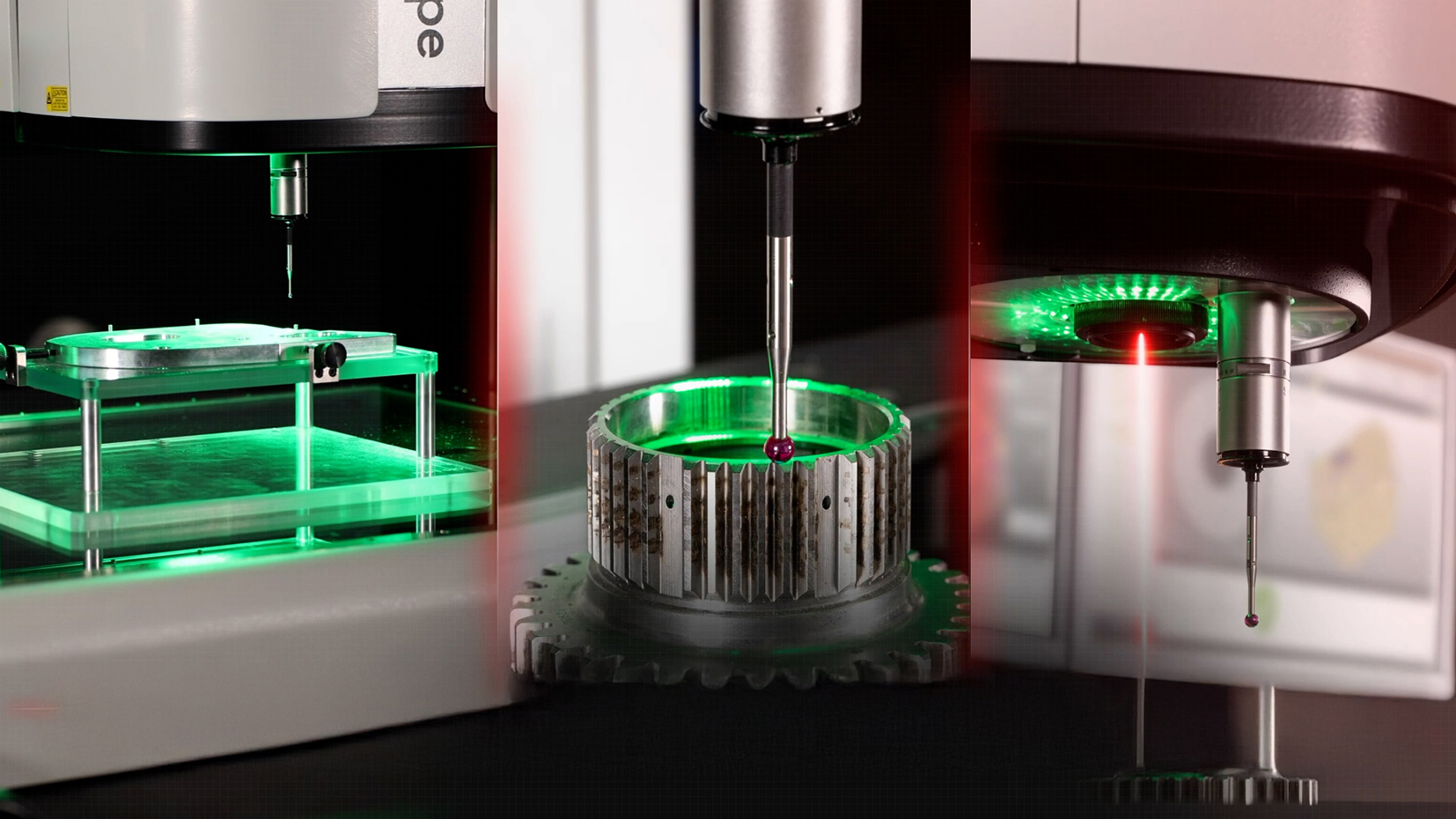

Building on the global success of the company’s previous SURFCOM product, the recently launched ACCRETECH SURFCOM NEX range is currently exceeding all anticipated sales projections. Rather than invest in two expensive, dedicated machines, cutting-edge SURFCOM NEX models allows users to achieve high-precision surface and contour measurements by the use of a single, cost-effective instrument. Moreover, as well as occupying much less space than two separate machines, the highly efficient new range delivers up to 60% faster measurement processes’.

Given the growing trend for component inspection to take place close to the point of manufacture, in addition to being ideal for use within pristine, temperature controlled cleanrooms, due to their ability to deliver accurate results across a range of temperatures, the robust SURFCOM NEX range can also be employed within serial production environments.

The new range’s innovations include the use of a flexible hybrid detector that allow simultaneous contour and surface measurements to be made. Rather than use a traditional ball-screw assembly SURFCOM NEX machines employs a progressive linear drive system that ensures rapid, low-oscillation measurements with no disruptive noises and vibrations.

Much of the success of the new range is based on the machines’ flexible modular platform. Rather than settle for a surface and contour measuring instrument that represents a near match for their requirements, potential customers are now able to specify a system that exactly meets their own specific needs. For example, the Hill Helicopters’ SURFCOM NEX 240 DX-13 machine was supplied with two separate detectors. In addition to an advanced hybrid detector that allows simultaneous high-precision contour and roughness measurements to be made in single pass, the DX-13 variant also boasts a high-resolution contour detector that provides an upwards and downwards measuring bias.

Tim Wood, ACCRETECH SBS Regional Director North Europe concluded. “ACCRETECH products enable the high-precision tactile and non-contact measurement of component’s surface roughness and profiles. Features able to be inspected include the measurement of roundness, flatness, levelness, concentricity, coaxiality, axial run-out, radial run-out, perpendicularity, cylindricity, parallelism and straightness.

“Thanks to their modular construction, our advanced test equipment can be adapted to meet individual clients’ specific requirements. As Hill Helicopters had several alternative suppliers to choose from, we were delighted to receive an order for a generous capacity SURFCOM NEX 240 DX-13 machine. This option has a 700mm x 450mm granite bed and a column with 450mm of travel. To further aid precision, the Hill Helicopters 240 DX-13 model was also supplied with an integrated anti-vibration table.”