Heller to emphasise engineering support

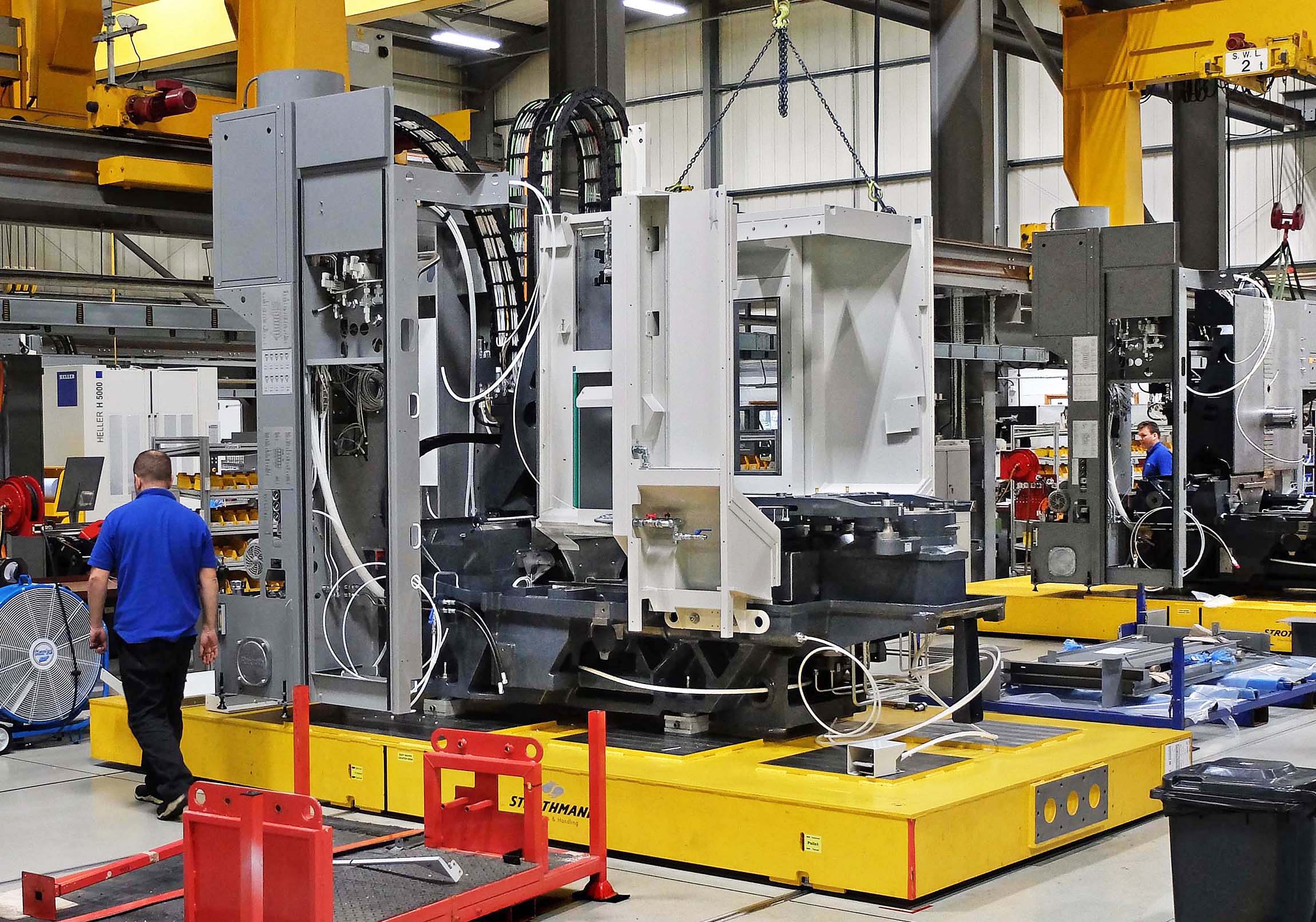

German-owned Heller Machine Tools whose factory in Redditch produces selected 4-axis and 5-axis horizontal machining centres (HMCs) for world markets, will stress at MACH 2024 that this facility places it in an excellent position to provide customers with an elevated level of applications and service support. The Worcestershire facility, which is celebrating its 50th anniversary in 2024, is also a global competence centre within the group for top-level turnkey projects and innovative manufacturing solutions.

360-degree solutions is Heller’s name for its pre- and post-sales services. Based on this principle, the machine tool manufacturer provides users with solutions to maximise machine availability and productivity, helping them to produce parts reliably and at a competitive cost per part in day-to-day manufacturing.

The holistic Heller service includes time studies which are accurate to ± 5 percent, evaluation of requisite workholding, consideration of automation and unmanned running requirements, built-in chillers for cooling the machine elements if they are required to achieve tolerance, tool life monitoring and broken tool detection.

John Dineen, Sales and Service Manager at Heller Machine Tools in the UK commented, “Our 360-degree approach to manufacturing solutions begins with understanding what the customer is trying to achieve and this entails looking closely at the enquiry and listening carefully.

“However, there is much more to it than that. We draw decisive conclusions from the discussions and communicate our finding clearly and precisely at all contact points with the potential user.

“To achieve this, every member of staff at Redditch requires agility and flexibility, as they are needed in order to adapt to what can be a rapidly developing situation when the pace of change accelerates during a project.”