Guhring to unveil comprehensive line up at Southern Manufacturing

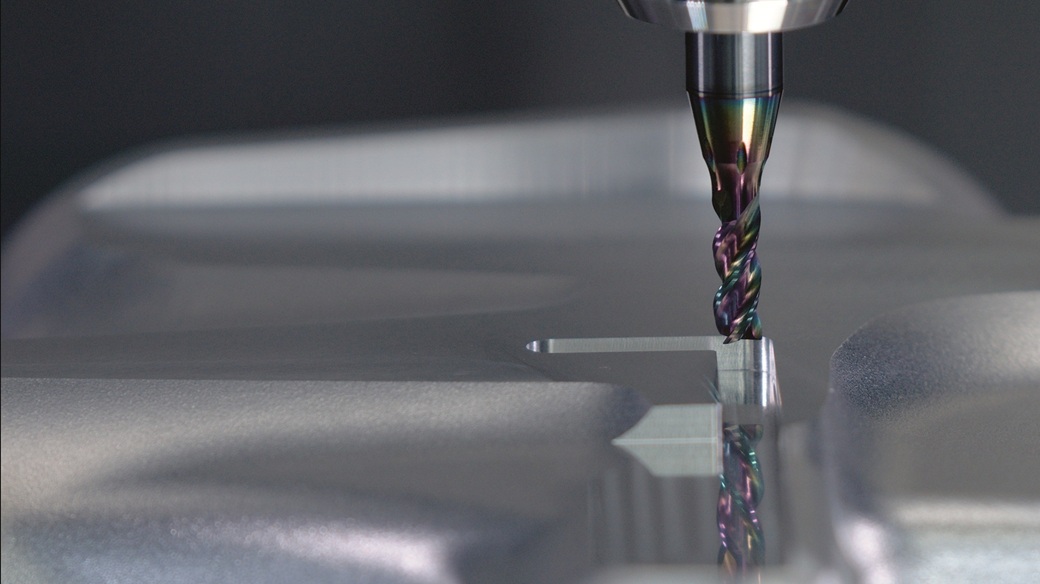

Visitors to Guhring’s stand (D200) at Southern Manufacturing & Electronics 2026 will discover an extensive portfolio of cutting tool solutions spanning drilling, milling, threading, reaming and deburring, with the company’s RF 100 AL milling line among the headline attractions.

Guhrings’ RF 100 AL series of solid-carbide end mills is available in diameters from 0.5 to 25 mm. The range is engineered for aluminium, other non-ferrous metal and plastic machining. The smaller RF 100 AL Micro achieves cycle time reductions of up to 76% compared with conventional small end mills, whilse the standard RF 100 AL delivers a 30% increase in machining performance with real-world data demonstrating 59% faster machining times and 54% longer tool life. Both variants feature Guhring’s ultra-thin Carbo+ coating, nano-polished round bevel support chamfer and GühroJet internal cooling system for optimal chip removal.

Available with either corner radius or corner chamfer configurations, the RF 100 AL Micro offers flexibility for end users by supporting ramping, slotting, trochoidal milling and plunging operations. Complementing the aluminium specialist at the exhibition, the RF 100 Sharp milling cutter represents Guhring’s sharpest cutting edge and is now available with corner radius options for enhanced versatility. This premium solid-carbide end mill is engineered to deliver smooth surface finishes and high precision across a wide range of materials.

Also on show will be Guhring’s drilling innovations, including the RT100 InoxPro drills and the ExclusiveLine micro-precision drill XL capable of achieving drilling depths up to 30xD, as well as the three-fluted FT 200 U for high-feed drilling technology. The modular BT 800 is an interchangeable-head drill system offering rapid head changes and extended overall tool life.

Threading innovations on display include the Energy tap, developed explicitly as the thread specialist for energy sector applications, and the XF fluteless tap that delivers dimensionally accurate threads in steel through material displacement rather than chip formation. The SC-TM-Z SP thread milling cutter impresses with its ability to complete an entire thread in just two passes, reducing programming complexity and cycle times.

Also on Stand D200 will be the HR 500 high-performance reamer. According to Guhring, it achieves speeds up to 50 times faster than conventional reamers, transforming finishing operations. Supporting these cutting tools, the GÜHROSync tapping chuck features clamping technology designed specifically for thread tapping and forming operations, while the new 208 grooving system for sliding-head turning machines delivers process reliability in grooving and parting-off in confined spaces.