Guhring – The ‘Pro’ for holemaking applications

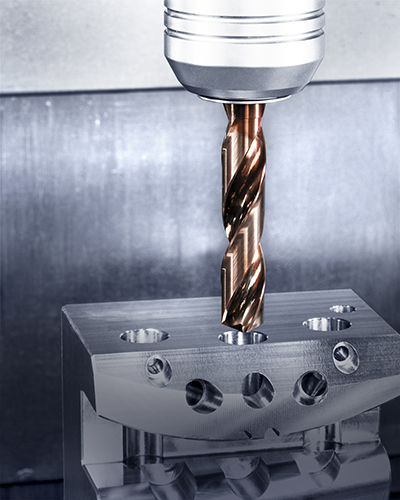

When it comes to holemaking, Guhring is an outright world leader and authority on the process – a fact supported by decades of expertise and the industry’s most comprehensive product portfolio. Now, the cutting tool experts have developed its latest addition to the range, the new RT100 InoxPro series of solid carbide drills.

Developed specifically for manufacturers drilling stainless steels and titanium alloys, the new RT100 InoxPro overcomes the challenges of tool wear with ease, delivering exceptional performance that is a combination of the latest tough carbide grade, the innovative new geometry and a formidable coating technology developed especially for this material group. It gives manufacturers a 50% increase in feed rates and productivity with a 60% improvement in tool life compared to conventional stainless steel drills. Furthermore, the ingenious geometry design of the RT100 InoxPro optimises swarf control and evacuation to ensure unsurpassed process reliability even when drilling up to 7XD.

The remarkable performance level of the Guhring RT100 InoxPro is achieved with an optimised sickle-shaped cutting edge that efficiently forms and evacuates swarf, an ultra-smooth Perrox coating that increases wear protection and premium polished flute surfaces that removes swarf from the cutting area at speed to prevent built-up edges. Available in 3, 5 and 7XD lengths, the RT100 InoxPro is manufactured from an optimised carbide grade that has an improved combination of toughness and wear resistance that prevents the cutting-edge from chipping to maximise tool life and performance.

Provided with a 140-degree point angle and coolant channels to support swarf removal and extend tool life, the RT100 InoxPro is available from 3mm to 20mm diameter in 0.1mm increments, with all imperial dimensions supported within this range. The extremely robust 3XD series has an overall length of 62 to 131mm and a flute length of 20 to 79mm, depending on the chosen diameter. In contrast, the 7XD range of drills has an overall length from 70 to 244mm with a cutting length from 30 to 190mm, making the RT100 InoxPro perfect for high-precision applications that demand unwavering stability and performance.

Complementing the new RT100 InoxPro is the ingenious new InoxPro fluteless taps. The new InoxPro succeeds where other taps fail. It has a perfectly synced macro and micro geometry with an optimised lubricating flute geometry and polygon shape, ensuring reliable fluteless tapping in stainless and other austenitic high-grade steels. To minimise tool wear, the Guhring InoxPro taps rely on an exceptionally smooth and temperature-resistant HiPIMS AICrN coating. This delivers unsurpassed tool life and perfect dimensional accuracy for threads produced in combination with water-mixed emulsions. To find out how the world leader in hole-making and threading can take your productivity, performance and precision to a new level, contact your local Guhring representative for more information.