Germany’s most advanced die-sinking technology is now available from Warwick Machine Tools

Following a recent agreement with Zimmer & Kreim (Z&K), the German manufacturer of advanced CNC EDM cavity sinking machine tools for the mould tool and die sector will be represented in the UK and Eire by Warwick Machine Tools.

Since its inception in 1985, Z&K has built an enviable reputation within its niche sector starting with the first machine it developed for the Danish toymaker, Lego. Today, the company has a range of ‘genius’ multi axis EDM machines designed and developed to match even the most demanding challenges from almost every industry sector.

Originally derived from the company’s control system developed in 2002, the name has now become synonymous with high-quality EDM machines from ZK. With the genius name, all machines by Z&K prove not only the intelligence of the machine control system, but also the stability of the basic structure, the high precision and the impressively simple programming.

With their compact design, they are the standout space-saving solutions in their respective machine class. Yet they still have all the features needed for perfect results and efficient processes in tool and mould making; including a continuously adjustable work tank, easily accessible, fixed tables, and a C-axis as standard.

Z&K models available from Warwick Machine Tools start with the compact genius 602. At under 1 m wide and only just over 1.5 m deep, this really is an EDM die sinker that can fit into any workshop. Although the footprint is minimal the 576 by 400 mm worktable is generous enough to accommodate substantial workpieces up to 500 kg. Axis travels of 350 x 250 x 315 mm in X, Y and Z provide the flexibility to generate high precision cavities using the 50 A generator in even the hardest conductive materials. Precision is assured with a 1 micron resolution in each linear axis and 0.001o in the C-axis.

Ideal for tall workpieces the genius 1000 is subtitled ‘The Cube’. It features axis travels of 700 mm in X, 500 mm in Y, and 500 mm in Z, and the 900 by 700 mm worktable is mounted on a mineral cast bed that can accept workpieces up to 1,500 kg. For even larger components the genius 1200 is constructed from cast iron and can accommodate up to 3,000 kg on its 1,200 by 850 mm worktable with axis travels of 900 x 680 x 405 mm in X, Y, and Z.

The genius 1200 is equipped with a 5-axis CNC control system and has two simultaneous drives, each with direct measurement systems for the X-axis gantry. This supports the processing of large electrodes as well as highly detailed work on larger parts. The tank can be continuously lowered, saving time. So, interruptions for pumping, flooding, or temperature adjustments are avoided and idle times are reduced.

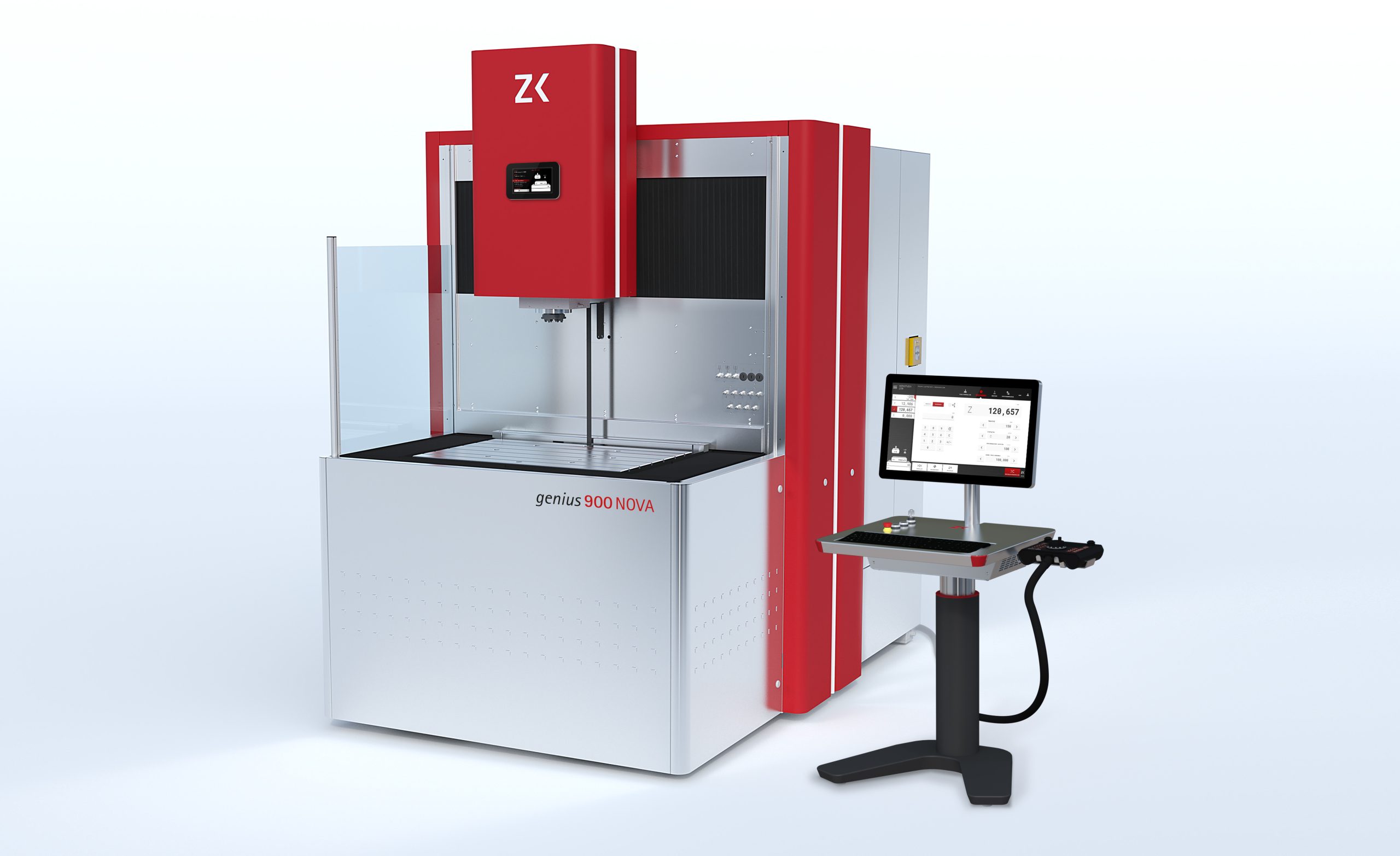

The latest machine developments from Z+K are the genius 750 NOVA and the genius 900 NOVA, and whatever the characteristic being measured including speed, accuracy and precision, stability, or flexibility, these EDM dies sinkers are the best in class. The compact substructure of each is made of cast mineral to ensure accurate working results, even in harsh environments with significant temperature fluctuations.

High-speed drives are used in all axes with 1G acceleration. At the same time, low-wear erosion with copper or graphite electrodes, as well as reliable process cycle times, are ensured thanks to the vibration damping of the mineral castings. Simultaneous 8-axis operations are supported along with manual eroding for teaching electric discharge machining via the joystick function.

The genius 750 NOVA has a 600 by 600 mm table with axis travels of 420 x 420 by 400 mm in X, Y, and Z while the larger genius 900 NOVA is fitted with a 600 by 900 mm table and offers an increased travel of 720 mm in the X-axis.

Ian Holbeche, Managing Director, states: “For die-sinking applications, the Z+K range offers exceptional performance benefits. The accuracy and execution of the erosion is among the best in the world, and each model has been designed and built with consideration for automated operation, be it from the initial installation or retrofitted to increase both the run time and efficiency of the machine.”