Four cutting heads, one vision: Prima Power’s Giga Laser Next

Prima Power has unveiled its latest innovation in 3D laser cutting technology: the Giga Laser Next. Specifically engineered to meet the rapidly evolving demands of high-volume automotive production, the new system represents a milestone in the industry’s ongoing transformation. At the core of Giga Laser Next lies a world-first configuration: four laser heads operating simultaneously on a single component within a cartesian machine. This synchronised approach boosts throughput and efficiency, making the solution relevant for the era of giga-factories and the growing use of giga-presses in electric vehicle (EV) production.

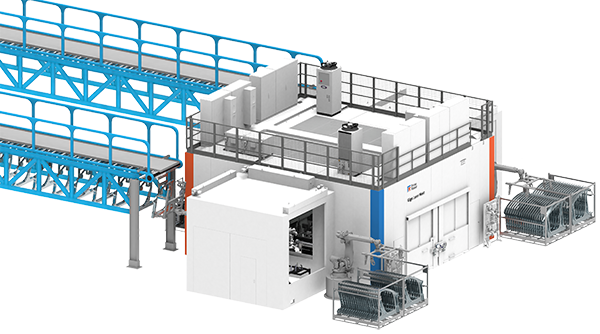

The new machine is designed to integrate seamlessly into fully automated production lines. Its dual-station layout enables simultaneous loading and unloading, while its compact 10×10 m footprint is achieved by positioning ancillary equipment such as laser sources and chillers on a mezzanine level. According to Prima Power, this efficient use of space, combined with a typical idle time of just 2 seconds, positions Giga Laser Next as a leader in space-time productivity.

Since the 1990s, high-strength steel (HSS) has become a mainstay of modern vehicle design due to its strength-to-weight benefits. However, traditional cutting and forming techniques often struggle with the material’s rigidity. This has led to a natural synergy between HSS and 3D laser cutting – a synergy that Giga Laser Next is designed to maximise.

As OEMs scale up to meet increasing demand and diversified model ranges, conventional laser systems may fall short in productivity and flexibility. Giga Laser Next addresses these challenges by offering over 280% higher productivity per sq m, reducing the number of cutting stations and average changeover times by up to 75%, and enabling fully unmanned, one-piece flow automation.

Backed by nearly five decades of experience, Prima Power has a strong track record of innovation in this field. From the earlier Optimo and Rapido to the high-speed Laser Next series, the company says it has consistently pushed the boundaries of 3D laser cutting. The Giga Laser Next is the latest evolution of this legacy.

Giovanni Negri, CEO of Prima Power and Prima Industrie Group, says: “This new solution represents the essence of our strategy – evolve by integration. By combining the productivity of four machines into a single compact unit, we’re delivering a solution designed around real production challenges.”

Giga Laser Next also features digital twin validation, easy fixture changeover, and long-term reliability with minimal maintenance requirements. With built-in capabilities for quality control, marking and direct connection to stamping or assembly lines, it’s positioned as a turnkey solution for future-facing automotive manufacturers.