Five technologies bring a new industry standard

Conventional deep hole drilling, especially when producing small diameter holes, is usually a slow and unreliable process. The special purpose DVAS mini drills have been designed from the outset specifically for drilling small holes in a wide range of materials.

The DVAS series is a total small drilling solution package. With a vast range of lengths ranging from L/D=2 up to 50 L/D and a dedicated set of short pilot drills that start at Ø1.0 mm and are available in 0.1 mm diameter increments up to Ø2.9, meaning that the pilot drill sizes match the sizes of the longer length drills and thus ensures complete compatibility across the whole drilling process.

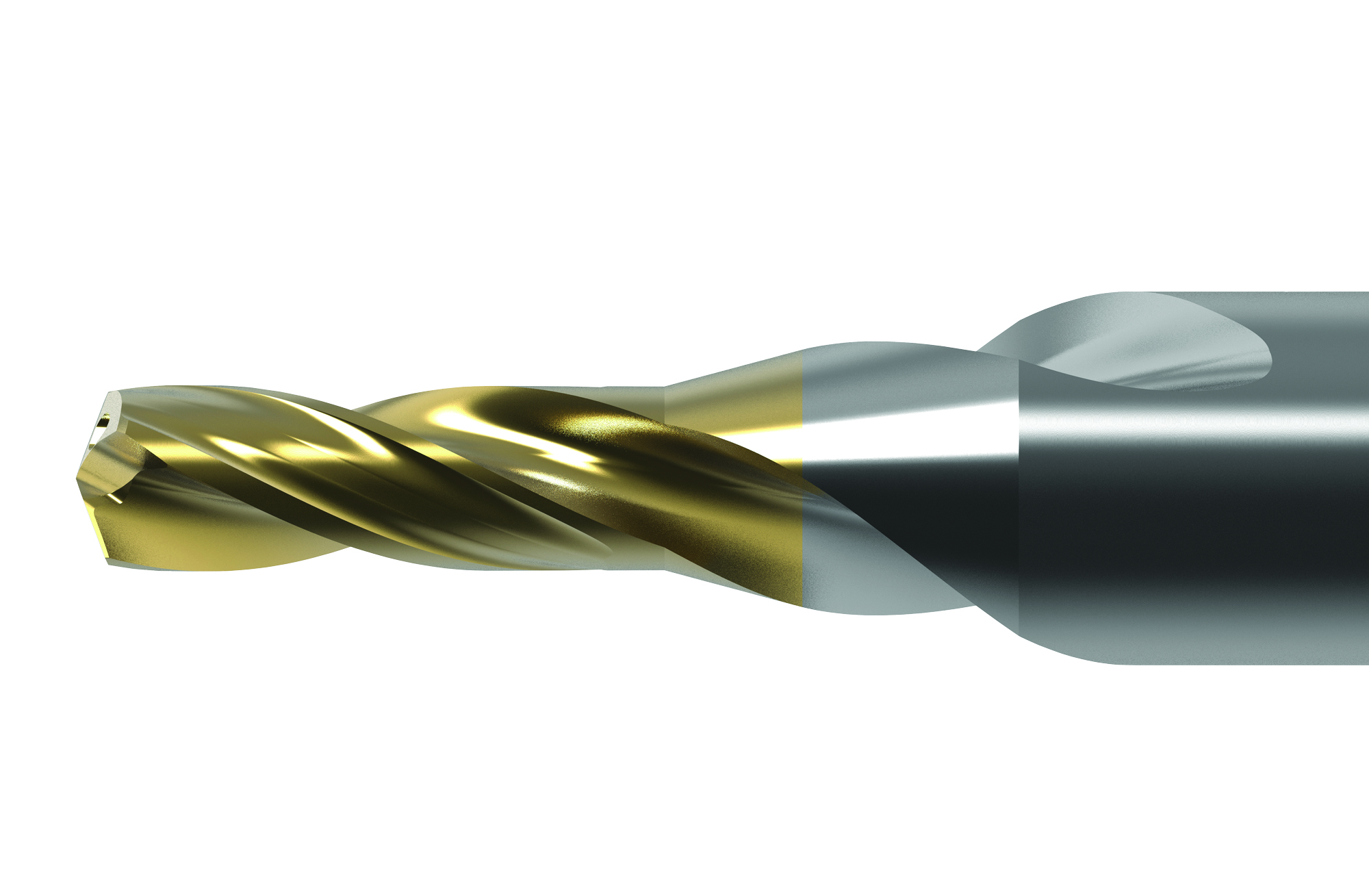

Starting with the important base material, a brand new micro-grain cemented carbide PVD coated grade called DP1120 was developed. The new multi-layer coating has an ultra smooth surface that prevents chip clogging and reduces the instances of breakage commonly found when drilling small diameter deep holes. The Tri-cooling technology is optimal for small diameter drills and can achieve more than double the conventional coolant discharge volume. This dramatically improves chip discharge and heat dissipation and contributes greatly to tool life and stability.