Five new machines set to take the spotlight at DMG Mori in-house exhibition

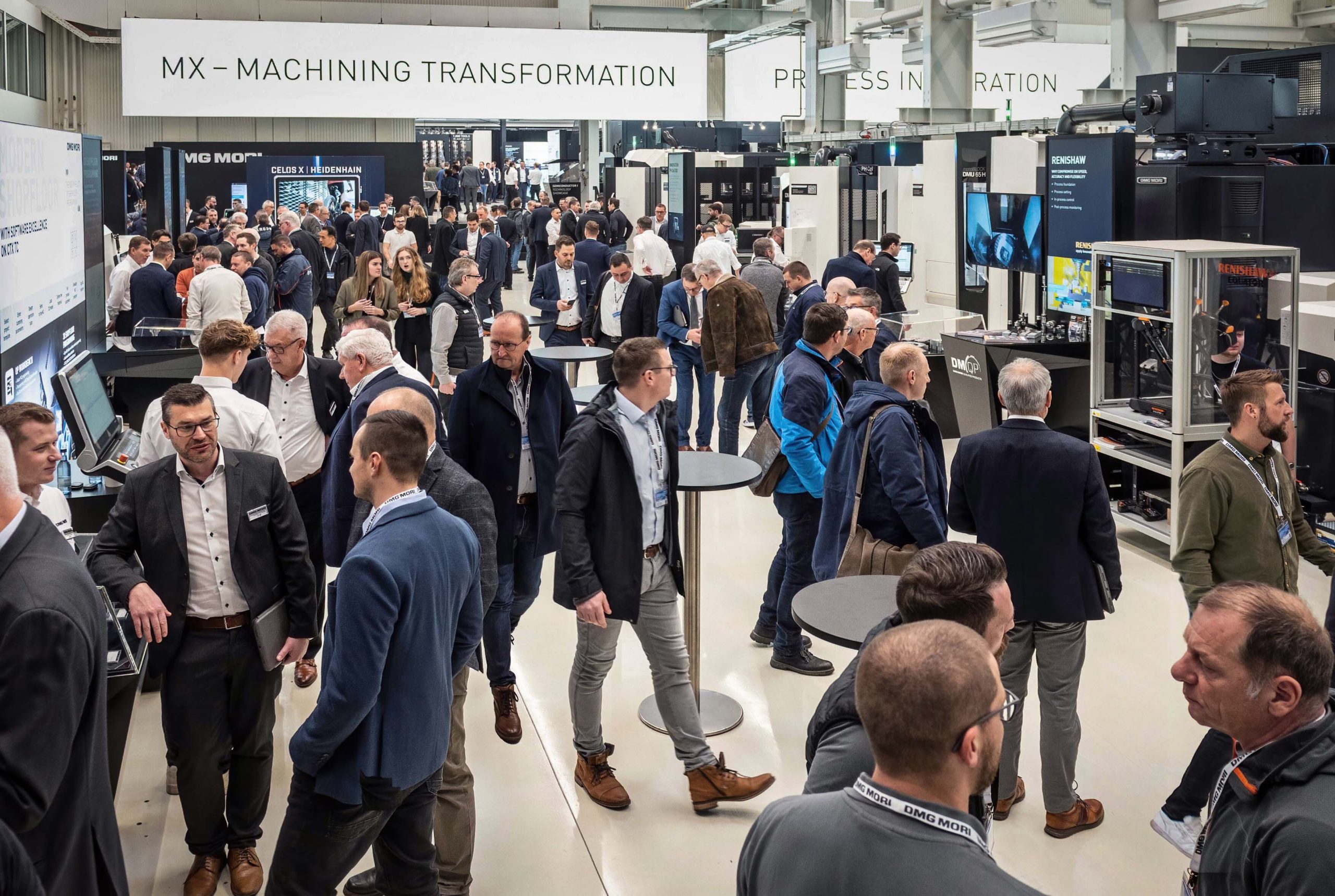

At its in-house exhibition in Pfronten, Germany on 10-21 February 2025, machine tool manufacturer DMG MORI will launch five production platforms under its machining transformation (MX) strategy. It was 30 years ago that the doors of the group’s largest European production site were first opened to customers, suppliers and other trade visitors.

DMU 60 eVo 2nd generation

DMG MORI says that its DMU 60 eVo 2nd generation 5-axis machining centre, with its proprietary table kinematics and proven machine concept, will further meet increasing demands for precision, dynamics and flexibility. The machine, which is set to make its world premiere at the exhibition, integrates several manufacturing processes including mill-turn machining, gear hobbing using the gearSKIVING technology cycle, and grinding.

The multifunctional machining solution can be adapted to suit a range of industrial applications. Intelligent automation solutions optimise machine utilisation around the clock, if necessary. Modern control options include a SINUMERIK One or HEIDENHAIN TNC 7, coupled with DMG MORI’s CELOS X interface with app-based functionalities.

ULTRASONIC 20 linear 3rd generation

New also will be the ULTRASONIC 20 linear 3rd generation 5-axis machine featuring ultrasonic-supported milling and optional grinding. The machine is suited to processing materials such as glass, ceramics and composites for the semiconductor industry. Experience gained from the installation of 600 predecessor models has allowed the manufacturer to raise positioning accuracy to 2 µm in the linear axes and 2 seconds of arc in the rotary swivelling axis.

The machining centre is the manufacturer’s most accurate simultaneous 5-axis model. Superimposition of tool rotation with ultrasonic amplitudes of up to 15 µm reduces process forces by 50% and enables higher feed rates, improved surface finish and longer tool life.

Future-proof production with DMX U series

Based on the design of the existing 3-axis DMV vertical milling machines, DMG MORI has developed the DMX 60 U and DMX 80 U production centres for 5-sided machining of complex workpieces weighing up to 300 and 350 kg respectively. With travels of 600 x 600 x 510 mm for the DMX 60 U and 800 x 600 x 510 mm for the larger model, the new machining centres cover a variety of applications, particularly in the die and mould sector.

The monolithic, cast machine bed incorporates wide roller guideways, endowing the machine with 45% greater rigidity compared to the predecessor series and enabling dynamic machining with rapid traverse rates of up to 42 m/min. Temperature compensation ensures thermal stability and hence consistently precise machining. Linear scales and direct drives in the X and Y axes support high positioning accuracy. The CELOS X app-based control, energy-efficient operation and numerous automation options are further features.

CTX 750|1250 for 6-sided complete machining

A sixth generation addition to the CTX universal turning machine series will be another launch at the show. In a footprint of just 11.7 sq m, the CTX 750|1250 is capable of machining workpieces measuring 700 mm in diameter by 1,290 mm long.

Twin-opposed spindles, an optional Y axis with ±85 mm of travel and 6,000 rpm driven tools ensure productive 6-sided machining of demanding geometries in a single set up. Rigid machine construction, linear guideways up to 55 mm wide, integrated cooling and linear scales from Magnescale guarantee positioning accuracies of 6 µm and 12 seconds of arc.