Five-axis HMC features chip-breaking function

NCMT has introduced to the UK and Irish markets the Makino a500iR, a five-axis, twin-pallet-change, horizontal machining centre (HMC) that is being offered with a choice of three spindles. One has a BT40 interface and a maximum speed of 14,000 rpm, while there are two with an HSK-A63 interface and a maximum speed of 20,000 rpm or 24,000 rpm. The latter variants have a 60 kW continuous rating, while the BT spindle is rated at 63/30 kW (15%/cont) and 303/120 Nm (10%/cont) torque.

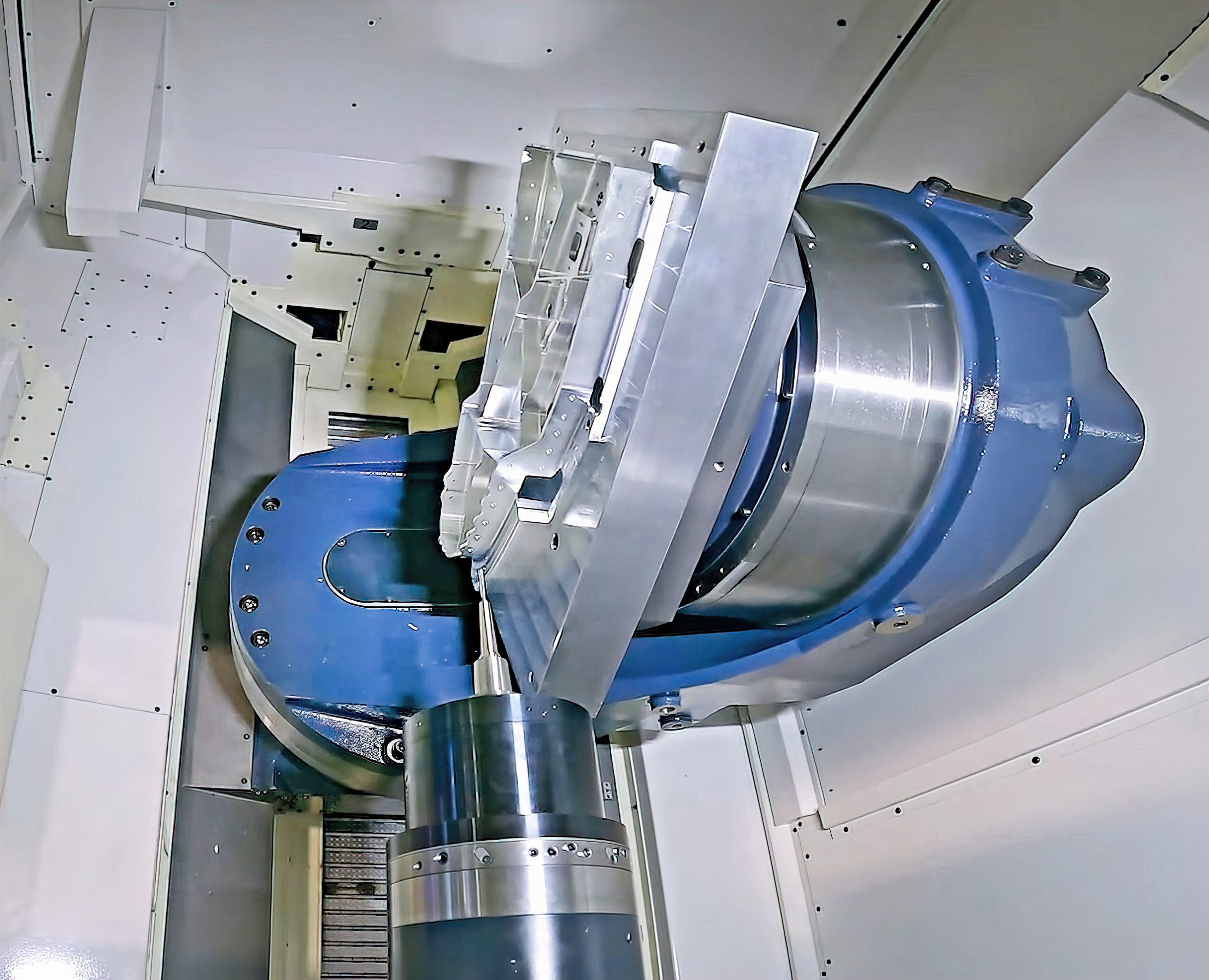

The centre of gravity of the 500 mm square pallet and fixtured workpiece is close to the vertical centreline of the -110 degree to +180 degree rotary B axis, enabling high-speed workpiece positioning at up to 267 degrees per second. The rotating C axis facing the horizontal spindle has an even faster rapid motion of 600 degrees per second. Maximum workpiece size is 900 mm diameter by 600 mm high and the table will accept a load of 400 kg. Linear travels in X, Y, and Z are 900, 750 and 800 mm.

As with all high-performance machining centres, the a500iR generates copious amounts of swarf that is efficiently evacuated by means of slanted panels in the working area and with the assistance of coolant delivered from the spindle head, nozzles and the ceiling of the chamber. The chips fall directly into a trough under the table along which a large volume of coolant washes them towards the stainless steel wire mesh chip conveyor. Coolant is also circulated under the C-axis rotary table to prevent accumulation of chips in that area.

Tool magazine variants are the standard ring-type with 90 pockets or optional matrix types with either 133, 218 or 313 positions. The ATC (automatic tool change) shutter opening is automatically adjusted by a ballscrew drive to match the length of the tool being exchanged, minimising the ingress of chips and coolant, while reducing the already quick 1.0 sec tool-to-tool change time. A camera in the tool magazine detects damaged or broken cutters more quickly than a conventional touch probe.

A new feature is the GI (Geometric Intelligence) breaker function, which introduces micro-movements into a drilling operation to break stringy swarf into small chips, avoiding accumulation within the hole and possible damage to the cutter and component. Manufacturers can therefore leave the Makino to run unattended with confidence. Ingenuously, the GI breaker works without impacting the cycle time. This is in contrast to options offered by other machine tool manufacturers that tend to lengthen a cycle.

The a500iR is equipped with eStabiliser in the control that ensures high-accuracy machining, even in environments in which the temperature varies considerably. It allows power to be saved by eliminating the need for air conditioning. Various other energy-saving functions are included that reduce the power consumed by the machine itself and its auxiliary equipment. Automated workpiece clamping is available via hydraulic and pneumatic supplies through the pallet and automation options are available, including a three-level storage and retrieval system for machine pallets.