FCR end mills ensure vibration-free machining

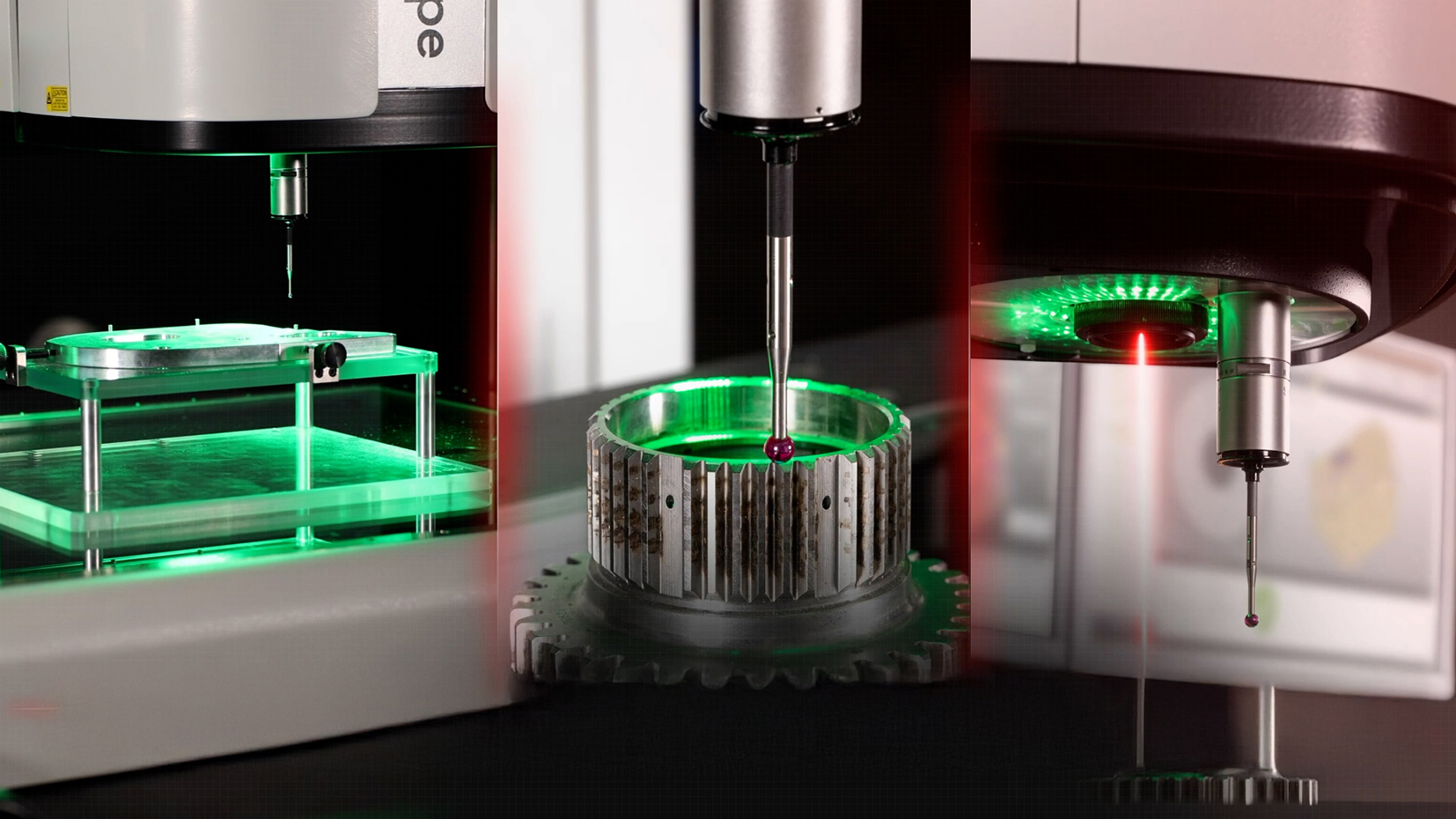

If you want to achieve vibration-free machining and impeccable surface finishes and tool life, Industrial Tooling Corporation (ITC) has now introduced the new Fullcut Mill FCR indexable end mills from BIG KAISER.

Incorporating a monoblock design, the new BIG KAISER system integrates the indexable inserts with the machine spindle in the BBT (BIG-PLUS BT taper) interface. To complete the range, the FCR end mills are also available in HSK A-63 and BDV interfaces. The monoblock design helps to reduce vibration and chatter whilst improving the rigidity of the system. As a result, manufacturers can achieve improved process reliability and consistency.

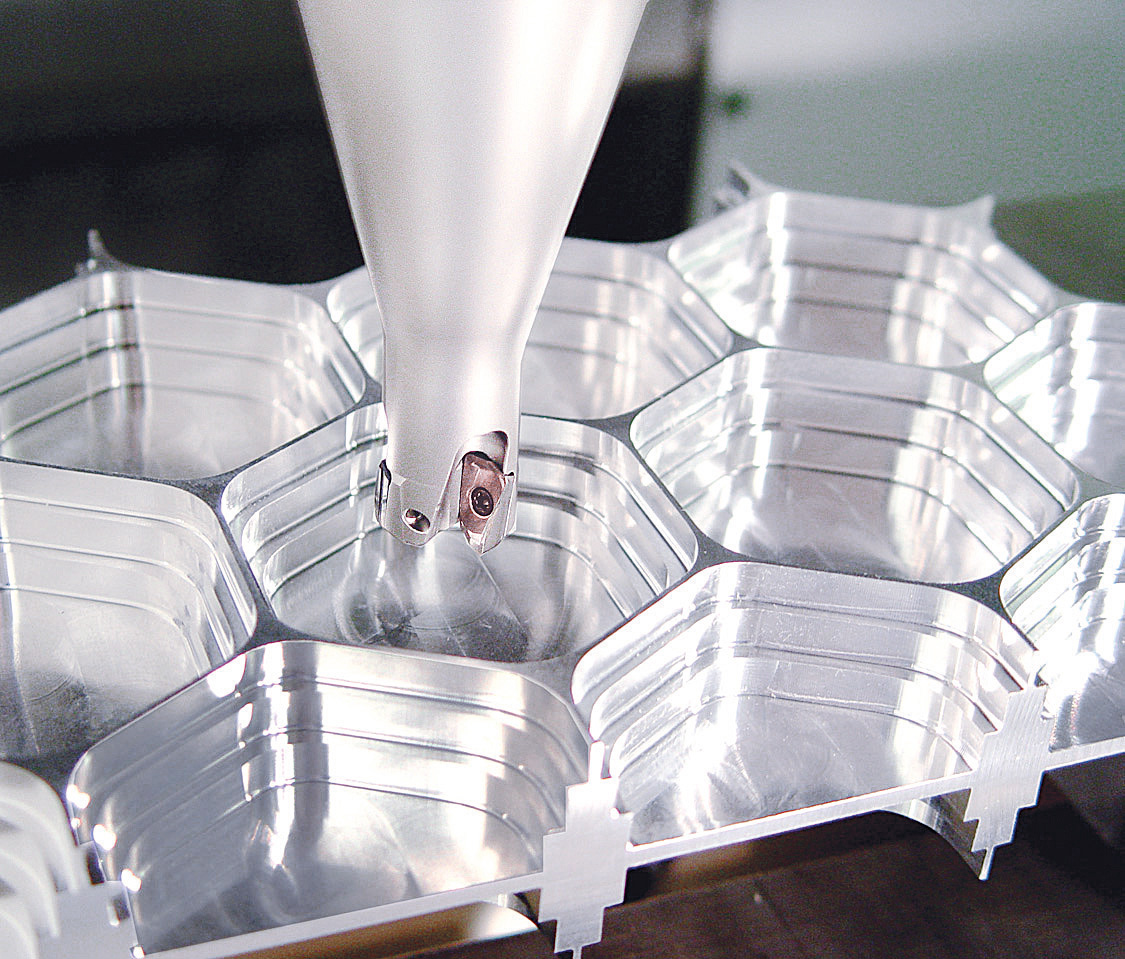

The Fullcut Mill FCR available from Tamworth-based ITC is an indexable insert tool that delivers excellent cutting performance for demanding milling applications. There are two variants available, the standard and long nose variants that are both supplied with a BBT interface. The FCR is available in 4 diameters that range from 16 to 32mm with two or three insert seats. The long nose version is more cylindrical and thinner, resulting in less interference contour. This is perfect for difficult-to-access work surfaces.

Compared to solid carbide end mills, the Fullcut Mill has significantly enhanced performance through its increased stability and lower running costs. This is a credit to users only needing to swap out inserts and not an entire solid carbide end mill. The advantage of the Fullcut Mill is the insert geometry that consists of a dedicated single-diameter geometry with a sharp cutting edge for both high radial and axial rake angles. This allows a smooth cut that requires less cutting effort and therefore less spindle power, leaving the surface smooth and burr-free. This special geometry makes them particularly robust even where there is a strong interrupted cut.

“The Fullcut Mill FCR is a versatile tool that’s able to handle multi-functional operations such as helical milling, peck-milling, grooving and shoulder milling. It is especially suitable for those typical hot mould materials with excellent tenacity. It is ideal for anyone who wants to achieve improved productivity and maximum material removal,” said Giampaolo Roccatello, Chief Sales & Marketing Officer for BIG KAISER Europe.