Expanded Metal boosts output with Kerf fibre laser cutter

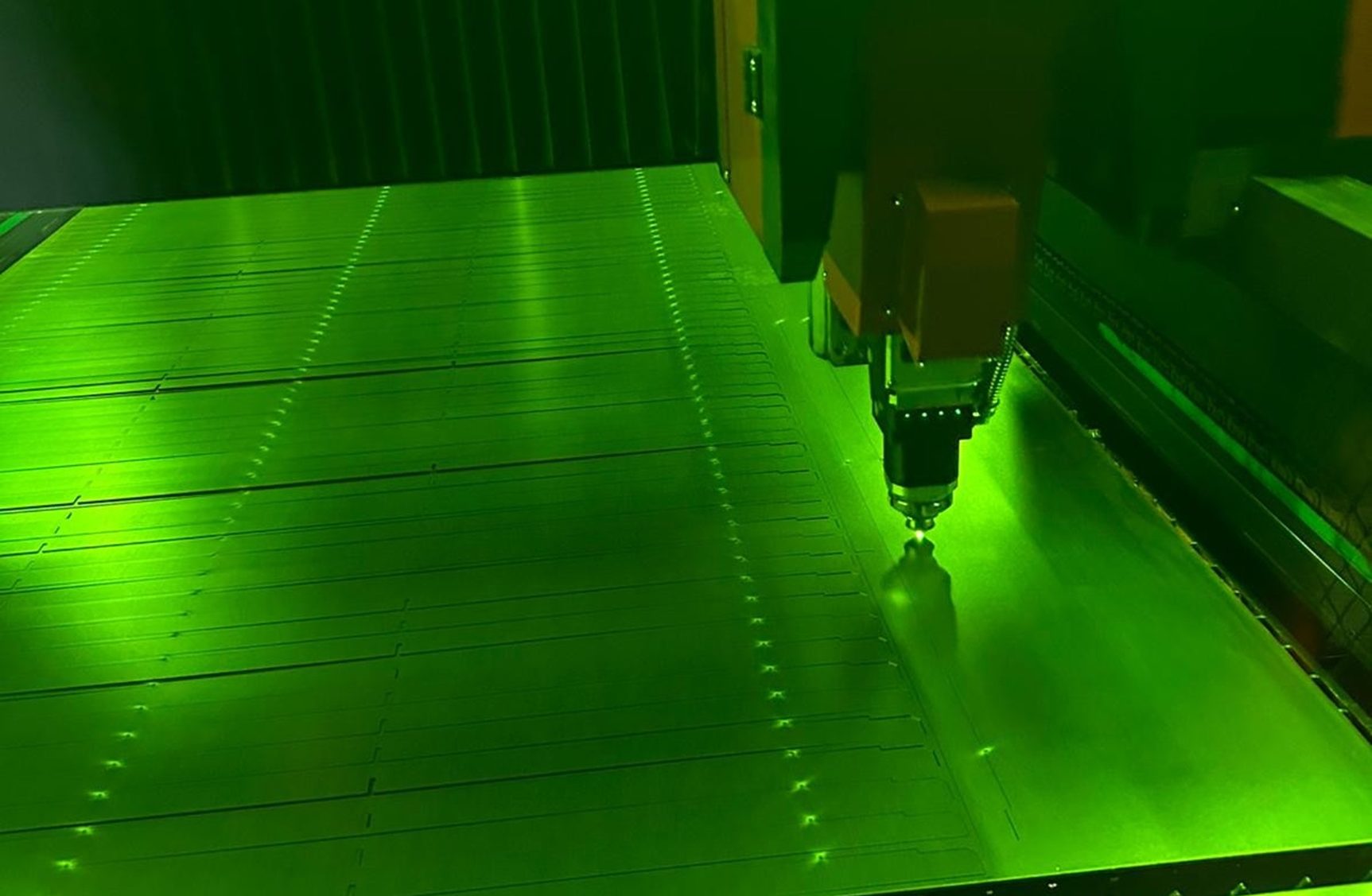

When The Expanded Metal Co recognised its costs for external subcontract laser cutting services were escalating in line with output, the Hartlepool-based manufacturer investigated the market for a fiber laser machine to help manage costs and enhance process control. The solution was a Lincoln Electric Linc-Cut 1530A 6kW fiber laser machine from Kerf Developments, and the benefits are impressive.

The Expanded Metal Co has a rich history that dates back to when its founder, John French Goulding, patented ‘expanded metal’ back in 1884. The company has evolved over the generations, with products ranging from mild steel and aluminium mesh to pre-galvanised steel and specialist products like ExMesh. The diversity of applications covers everything from balustrading, cladding, ramps, walkways and insect guarding in the construction industry to air and liquid filtration, security fencing, crop drying, animal flooring, acoustic applications, and even speaker and car grilles for the automotive industry.

For the past four years, the fabrication department has been buying laser-cut parts to complete fabricated assemblies that, as a finished product, are disability access ramps. Initially, the customer requirement was for four or five different ramp variations, but this has expanded to over 25. With ramps ranging from 900 x 300 mm to 1,500 x 1,500 mm and a host of dimensional variations in between, production volume now stands at 200 to 250 ramps a week. This increased volume created several issues for the northeast manufacturer. Firstly, subcontract laser cutting costs had escalated to become a major monthly cost, and secondly, Expanded Metal had to schedule its production and lead times around its supply chain.

Recalling the situation, Ryan Pinder, Operations Manager and Head of Continuous Improvement at the ExMesh subsidiary of the Expanded Metal Co, says: “Our laser cutting costs were climbing, and production schedules worked on min-max order levels with our supplier. It had to change. We looked at 8 to 10 laser manufacturers and really did our due diligence. Part of this included visiting MACH 2024, where we talked to a contact at Lincoln Electric. We have lots of Lincoln Electric weld sets, and it is a hugely trusted and well-respected brand that has never let us down. We told our Lincoln representative that we were in the market for a 3 kW laser, and he immediately introduced us to Dan Taylor from Kerf Developments as the technology partners were sharing a stand at MACH.”

Despite looking at many vendors, a demonstration at the Kerf showroom in Rochdale sealed the deal.

“This was our first laser purchase, so we needed support and reassurance as we leapt into the unknown,” he adds. “The Kerf team put us at ease and emphasised their level of support, and they couldn’t have been more supportive during demonstrations. We switched our requirement from a 3 kW to a 6 kW fiber laser to futureproof our business, and Kerf introduced us to the Lincoln Electric Linc-Cut 1530A.”

The Linc-Cut 1530A has a 3 x 1.5 m bed and incorporates an automated double shuttle table with 1-tonne capacity for loading and unloading sheets while the machine is cutting. The fibre laser cutting head has a 75 μm compact laser source to enhance cut quality. Furthermore, it incorporates an autofocus function with automatic gas calibration and cutting height for optimised cut quality and repeatability.

Kerf conducted cutting trials and invited the ExMesh production team to trial the machine. At the same time, the ExMesh Health & Safety Manager reviewed the safety attributes of the Linc-Cut 1530A. With a two-camera safety system, protective enclosure, security windows, light safety barrier, high-grade laser, CE certification, a fume extraction system with DigiFilter and a two-year warranty, the Linc-Cut 1530A passed the stringent health and safety requirements of ExMesh. Demonstrating its ease of use, the large-screen CNC interface integrates two monitoring cameras and automated drawing, nesting and database parameters with advanced functions like Flycut, Fast Cutting, Smooth Microjoint, Frame Border and Circle Centering, sealing the deal for the ExMesh operators.

Delivered in August, the Linc-Cut 1530A has hit the ground running, operating for 8 to 16 hours a day. The impact of the machine has been far-reaching. Subcontract supply of laser-cut components ended immediately, saving the 95+ employee business significant monthly costs. This will ensure the Linc-Cut 1530A has a short payback period.

“Despite its build quality and brand reputation, the Linc-Cut 1530A is also a cost-effective machine designed and engineered in Europe,” says Ryan Pinder. “While we have to build labour and consumable costs into our ROI projections, we’re already using the machine for much more than it was purchased – meaning it will pay for itself in the very near future.”

The ISO9001, 14001 and 45001 certified manufacturer has started moving work from punching and pressing machines to the laser.

“Punch and pressing requires tool changeovers and considerable set-up times. Now, we can put jobs straight on the laser and eliminate all that extra work. It’s much faster than our punching machines with much better cut quality. For every job, our first thought now is, ‘Can we put it on the laser?’ This is particularly the case for small batches.”

The Linc-Cut 1530A from Kerf Developments also streamlined lead times and inventory management.

“Working to min-max level with our supply chain, we had to stock inventory of over 1000-off of multiple parts to feed into our subcontractors. This stock level has already dropped to 300-400, which will diminish further, freeing up valuable space and eradicating excess material and stockholding. From a lead time perspective, we don’t have to work to 30 days by waiting for our suppliers. We can now do the laser cutting ourselves, reducing a 30 day lead time to a matter of days.”

Looking to the future, ExMesh purchased the 6 kW Linc-Cut 1530A to open opportunities beyond its current scope – and this is already reaping rewards.

“With the Linc-Cut 1530A, we’re now in charge of our destiny, and we’re already receiving more bespoke subcontract jobs from existing customers,” concludes Ryan Pinder. “Our ambition has always been to offer the Linc-Cut 1530A capacity as a subcontract service, and this is already the case. The next stage for our business is to invest in a press brake, where we can laser cut profiles and then fold the parts – expanding our subcontract scope significantly. So far, we’ve cut everything from 0.7 mm aluminium to 10 mm thick stainless steel and the opportunities are significant.”