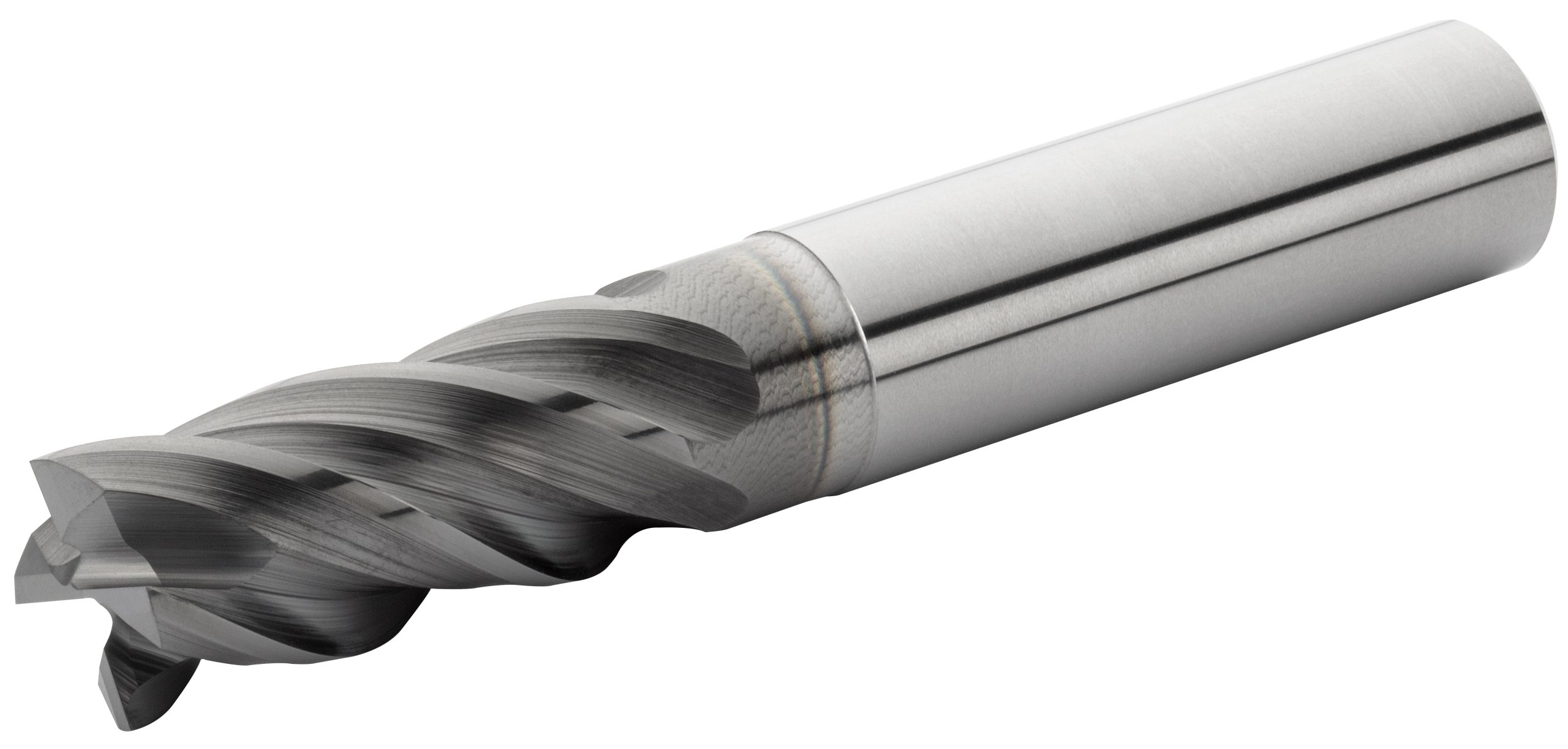

End mill innovation from Mitsubishi Materials

VQ, the top of the range series of carbide end mills from Mitsubishi Materials has recently expanded to include a new innovative type, the VQ4MVM. This latest addition is ideal for machining stainless steels and difficult-to-cut-materials including titanium and heat resistant super alloys. The modern metal cutting world also demands versatility and a reduction of cutting tool inventory, therefore it is also suitable for carbon and alloy steel applications.

VQ4MVM is multi-functional with a strong ramping capability of up to 30° on a wide range of materials. This eliminates the need for a pilot hole when machining pockets, thereby reducing costs through tool consolidation. Compared to direct plunge cutting, ramping enables simultaneous multi-axis feed at high speeds..

The reliability and high performance of all the new VQ4MVM end mills can be attributed to the (Al,Cr)N coating which delivers substantial resistance to wear. The special ramping capability of up to 30° is made possible by several innovative features. The end face geometry includes 2 separate gashes. These combine to provide super-efficient chip evacuation that far exceeds conventional designs when ramping.