Emsea boosts productivity and efficiency with Lantek Bend software

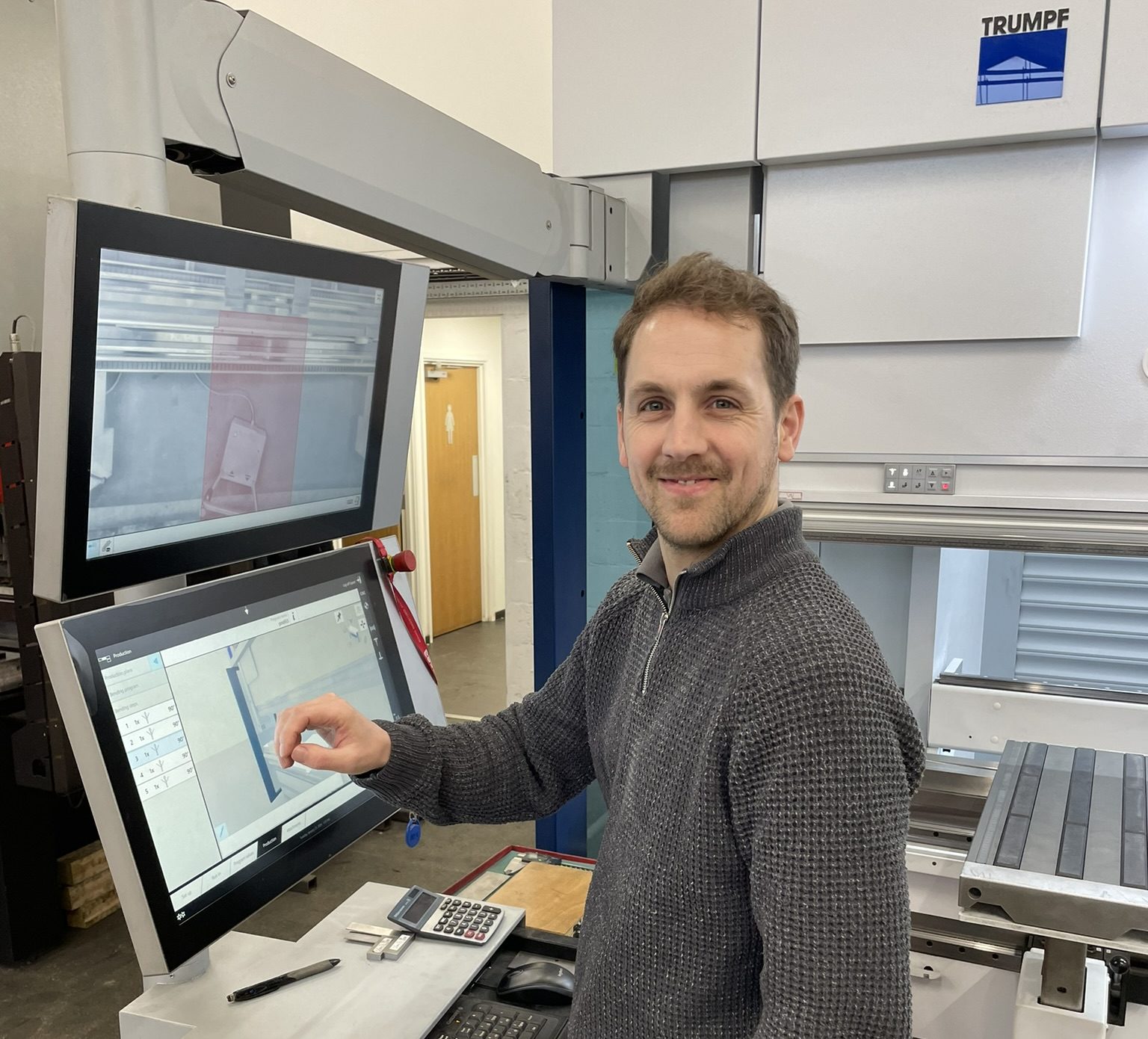

Emsea – a Tewkesbury-based specialist in laser cutting, metal fabrication, machining and sheet metal forming – has boosted productivity and efficiency by implementing Lantek Bend on its Trumpf TrueBend 5000 series press brake.

Lantek Bend’s multi-vendor capability gives Emsea flexibility by enabling the software to interface seamlessly with bending machines from different manufacturers. This provides a standardised process for programming and optimisation, ensuring consistency in production and cost estimation regardless of the machine used.

The software monitors material spring-back and calculates the necessary overbend to achieve precise angles. It can also detect if parts are inserted incorrectly, reducing errors and improving quality.

Jordan Adlam, Sales Engineer at Emsea, explains: “Thanks to Lantek’s advanced technology, we optimise machine productivity by cutting set-up times and avoiding errors, resulting in significant cost and efficiency savings. The integration of Lantek software products allows us to share and optimise data, operating efficiently while delivering excellent customer service.”

Emsea uses Lantek Bend not only for its Trumpf TrueBend but also other bending machines, providing operators with tooling and setting lists plus bending sequences. This efficiency saves time and ensures accurate cost quoting for different processes.

Serving industries such as agriculture, oil and gas, water, food, medical, and packaging, Emsea faces constant changes in materials and component types, making process automation crucial. Previously, bending sequences and tooling were worked out manually on the shop floor, leading to a risk of human error and material waste.

With Lantek Bend, Emsea benefits from a single floating licence integrated into its laser and waterjet machine programming and quoting processes. This integration has cut press brake set-up times by 50% and eliminated human errors.

“The reduction in set-up times allows us to offer better value to customers,” says Jordan Adlam. “Lantek Bend’s flexibility lets blank sizes automatically feed into Lantek Expert for nesting and cutting. Unlike other software, it allows changes to material, tooling sizes or bend radii on the fly. This flexibility, along with more accurate material pricing, is a major advantage.”

He adds: “Lantek Bend is simple to use. We import customer 3D CAD models, which the software breaks down into components, unfolds each part and determines the most efficient bending method with minimal tool set ups.”

The TSO batch job feature is particularly valuable for Emsea, allowing the company to group large batches of diverse parts. The TrueBend’s ACB Wireless and ACB Laser technologies complement Lantek’s software, which analyses all bends, sequences them efficiently and provides tooling lists to minimise tools needed. This reduces set-up times and maximises efficiency.

Emsea has been a Lantek customer since 2004, also using Lantek Expert for laser and waterjet programming, and Lantek Integra for production management and daily quotations.