Embracing the future at igus: AI’s transformative impact on manufacturing

The new AI Opportunities Action Plan outlines the ways that Government plans to ramp up the adoption of artificial intelligence (AI) across the UK to boost economic growth, increase jobs for the future and enhance everyday lives. A sector that is already seeing the immense impact of AI is manufacturing, and with the support of leading technology firms and £14bn in funding, AI demands to be taken seriously. Manufacturers like igus are navigating the complexities of Industry 5.0, where AI stands at the forefront, driving unprecedented advancements in efficiency, precision and innovation, while emphasising the importance of maintaining human creativity.

A new dawn for production processes

AI’s integration into manufacturing processes is reshaping the industry. Technologies, such as predictive maintenance and real-time quality control, are enhancing every aspect of production, Motion plastics manufacturer, igus, offers smart maintenance solutions i.Cee (predictive maintenance) and i.Sense (condition monitoring) to enhance operational efficiency and prevent unexpected downtime.

i.Cee leverages AI to analyse data from machinery sensors, and monitor the condition of components such as cables, bearings and energy chains. By collecting data on factors such as temperature, humidity, and vibration, i.Cee enables dynamic service life calculation, determining the optimal time for scheduled maintenance. This proactive approach reduces unexpected downtimes and maintenance costs, ensuring smoother operations and increased productivity.

Condition monitoring technology, i.Sense , also uses AI to monitor the condition of machine components. Any values that arise outside the expected limits result in an alert or notification that maintenance is required. This information provides the basis for planning time for maintenance, made possible through its ability to detect potential issues before they develop further.

Enhancing quality and precision

AI is making significant progress in providing accurate and tailored solutions to problems. Advanced computer vision systems powered by AI can scan products in real-time and identify defects or areas for improvement with incredible accuracy.

The igusGO app demonstrates this new use for AI, allowing anyone to photograph an application and its surroundings, where they are met with product suggestions that will enhance the performance of their machine. This not only ensures the use of higher quality products to optimise performance but also greatly cuts down the time spent searching for the perfect solution.

Smart factories: the future of manufacturing

The concept of smart factories, where AI and other advanced technologies create automated and flexible production environments, is also becoming a reality. These factories use real-time data analytics and AI to monitor and adjust production processes autonomously, maximising efficiency while minimising waste.

This level of automation and adaptability is essential for manufacturers to stay competitive in a fast-paced global market.

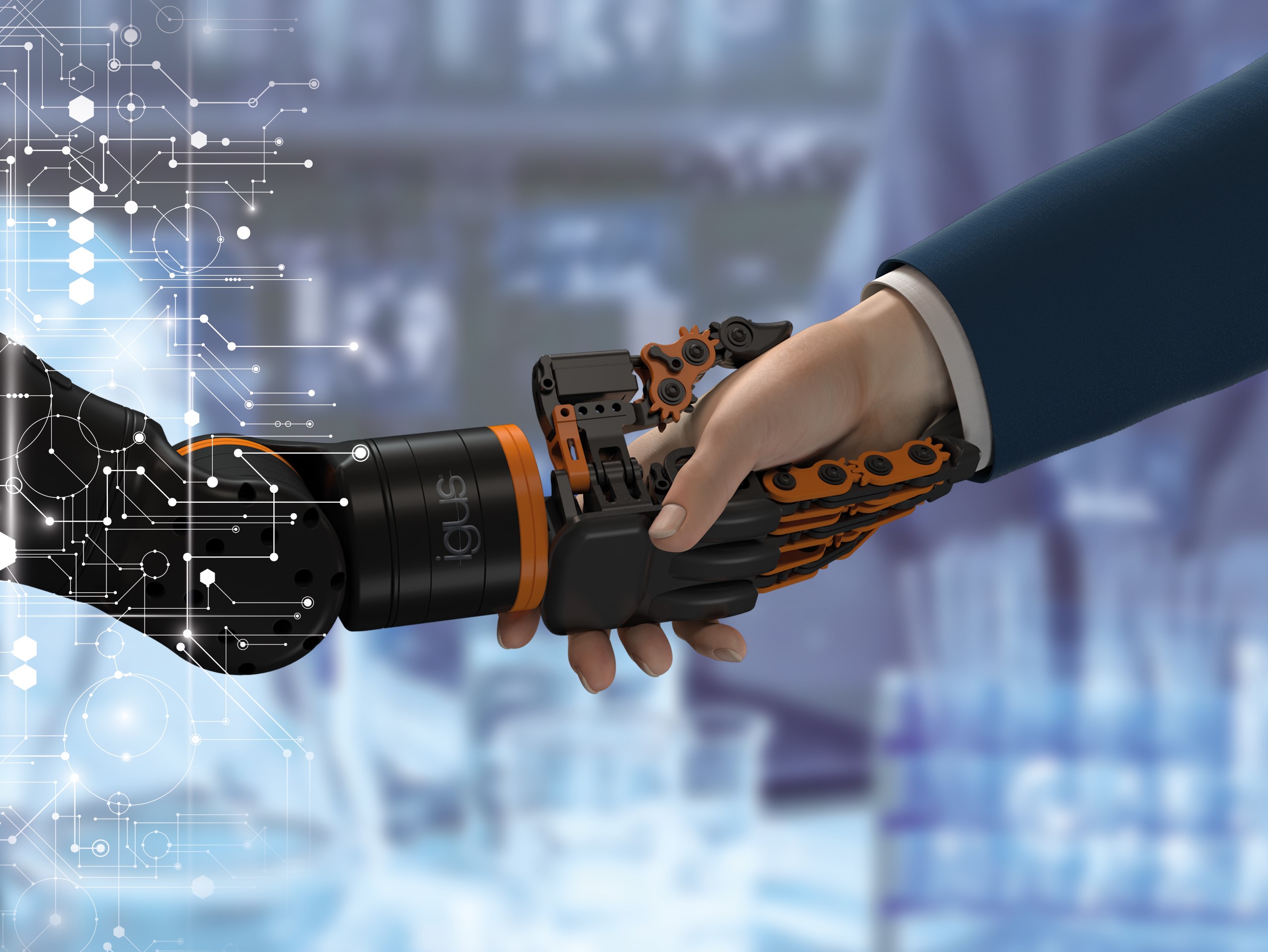

Human-robot collaboration

AI is also transforming the workforce in manufacturing. Collaborative robots, or cobots, such as the igus ReBeL can work alongside humans, taking on low-skill tasks that allow employees to focus on more complex and fulfilling work. This collaboration not only enhances productivity but also improves workplace safety and job satisfaction.

Looking to the future, the role of AI in manufacturing will only continue to grow. By embracing AI and the opportunities it creates, manufacturers can reach new levels of efficiency, quality and innovation, positioning themselves at the cutting edge of the industry. The journey towards realising the full potential of AI in manufacturing is ongoing, but the benefits are already clear. Those adopting these technologies now are undoubtedly shaping the future of manufacturing.