Electro-hydraulic linear actuators suit pressing, joining, forming, clinching and punching applications

Among current customer projects at CyTec Systems UK, the official sales partner for AHP Merkle products in the UK and Ireland, involves AHP Merkle’s energy-efficient electrohydraulic linear drives. This innovation not only offers new opportunities for clients but also presents what the company describes as a game-changing chance for users to advance their presswork processes with minimal ecological impact.

Previously, the customer presses were powered by an energy-optimised hydraulic power unit. The system used a 75 kW motor and a modern axial hydraulic pump to generate the necessary hydraulic energy. With the new electrohydraulic drives, power consumption has been reduced by 80%, while the working environment is also quieter (operating below 60 dBA). This eliminates the need for complex noise protection measures and, best of all, removes the need for hydraulic piping. Our customer now saves an entire technical room that would’ve otherwise been used for the hydraulic power unit.

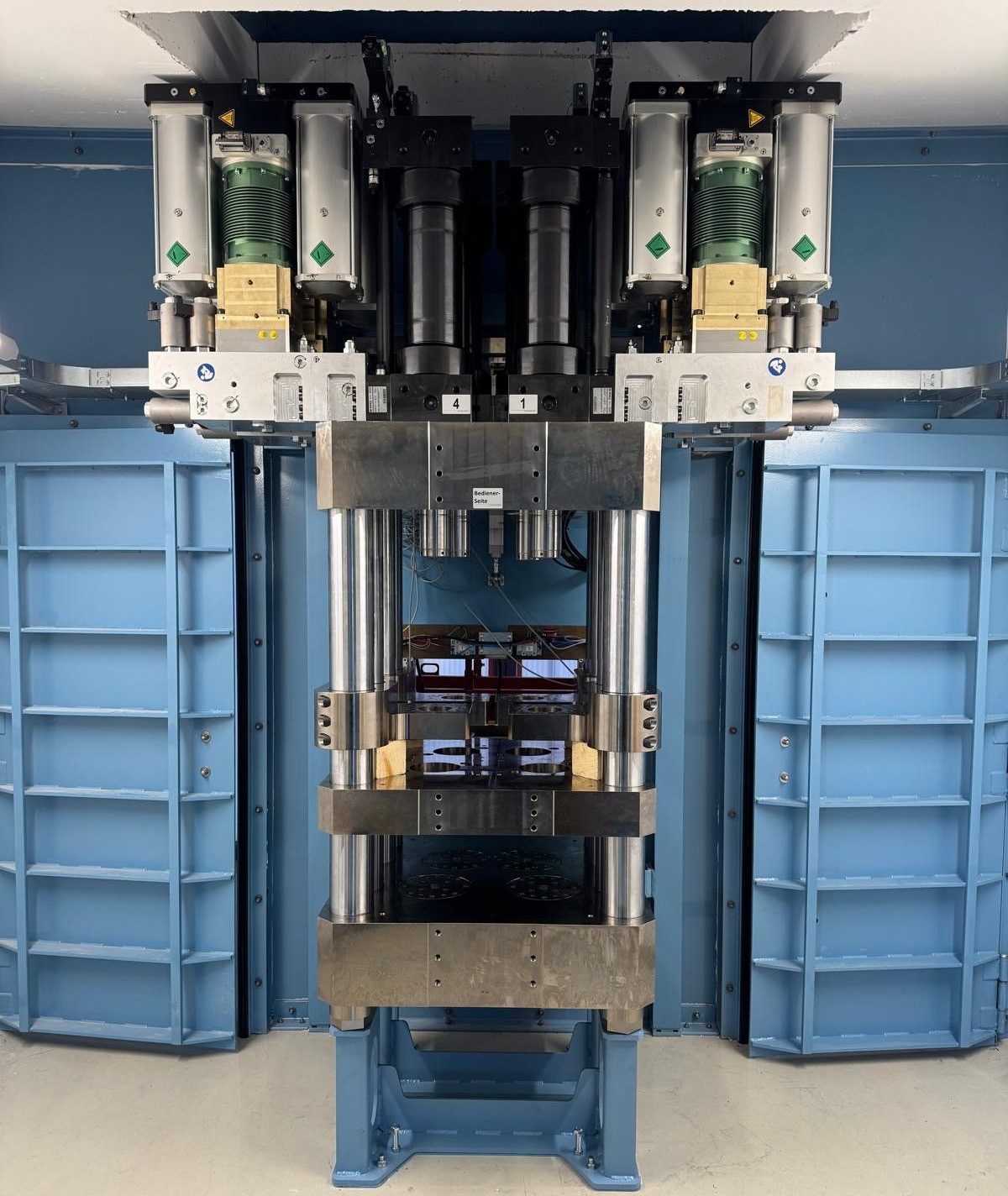

In this case, four drives, each with a pressing force of 250 kN and a maximum speed of 150 mm/s, operate in parallel, independently, with precise control. To top it off, the system includes a production data acquisition tool that tracks every step of the process in minute detail.