Discover engineering excellence Visit Southern Manufacturing & Electronics

Cutting-edge technology from across the engineering spectrum awaits visitors to the next Southern Manufacturing & Electronics trade fair, which will take place from 4th to 6th February 2025 at the Farnborough International Exhibition & Conference Centre. The new owner of the show, Easyfairs, says that a particularly high level of interest in the run-up to the event indicates that it will be a sell-out again.

Widely regarded as the largest and most comprehensive annual industrial exhibition in the UK and a major international showcase for engineering and manufacturing technology, the event is split approximately equally between exhibitors operating in the mechanical engineering and electrical/electronic sectors. It is important enough to attract big-name companies, but it is also readily accessible to the rich ecosystem of SMEs and smaller vendors across the UK and beyond.

To give a flavour of what will be there, from the exhibitor list we have selected a few companies that will be presenting advanced machines and equipment at the show.

Yamazaki Mazak will demonstrate its latest high-performance turning centre for medium to large volume production, the HQR-200/3 NEO. It is of twin-spindle, triple-turret configuration for one-hit production and is said to offer high accuracy, efficiency and profitability. Simultaneous, balanced cutting at both spindles reduces cycle times by up to 25% compared with a twin-turret machine.

The 22 kW / 5,000 rpm spindles provide powerful turning capability, while a 6,000 rpm milling spindle supports everything from end milling to high-speed drilling. The lathe integrates seamlessly with automation solutions, from bar feeders to robotic machine-tending setups, enabling flexible and unattended operation. The model’s long Y-axis stroke enables machining of complex geometries.

The HQR-200/3 NEO is the latest machine to be engineered to align with Mazak’s Go Green strategy that reduces its environmental impact. There will also be a chance to see the new Mazatrol SmoothG3 CNC fitted to the lathe, featuring three channels for intuitively helping operators to optimise tool paths, reduce unnecessary tool changes, balance machining time for each turret and prevent collisions.

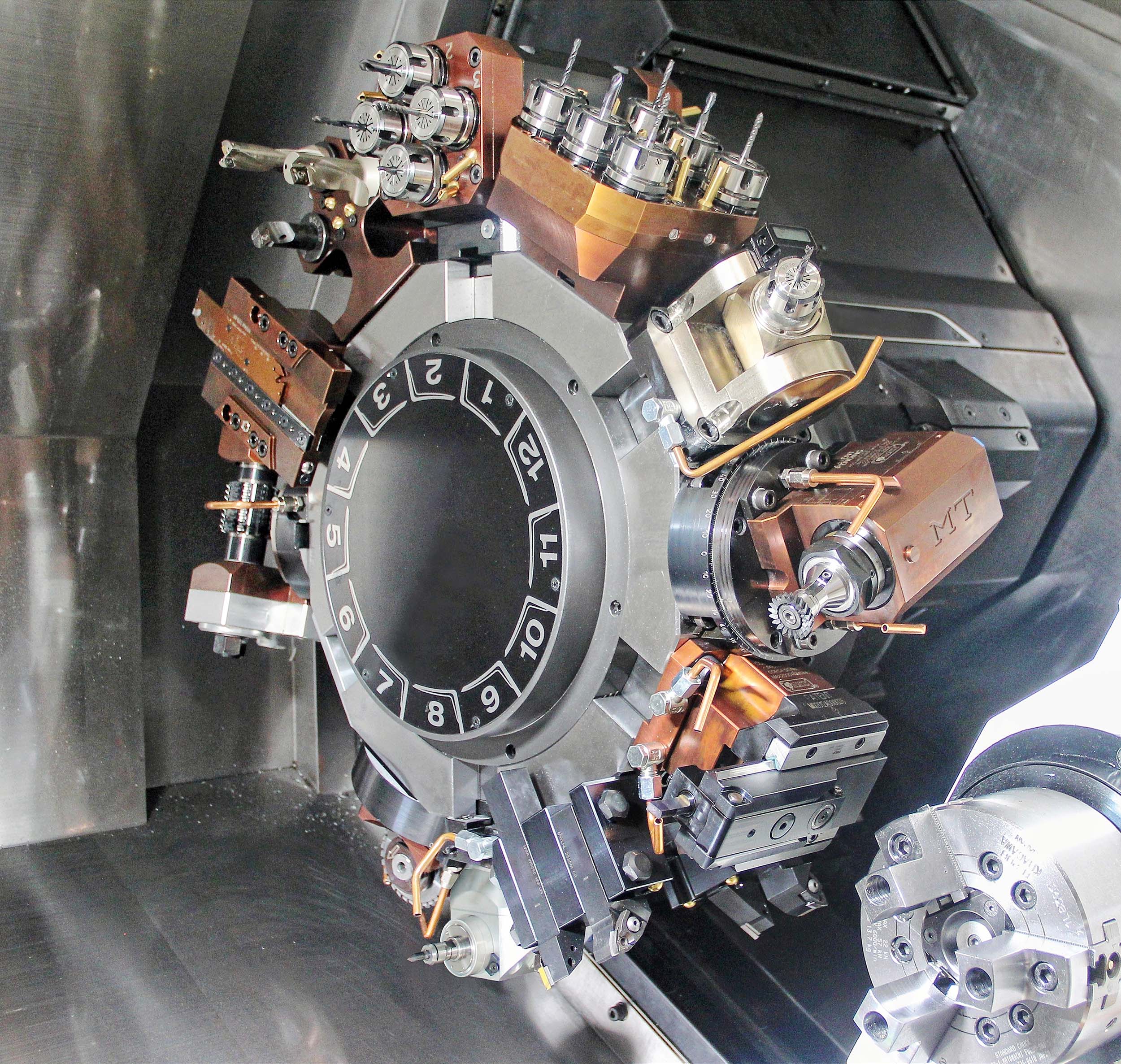

Machine Tool Supplies, one of the UK’s leading specialists in the supply of driven and static toolholders from MT Srl for CNC lathes, angle heads and speed increasers from OMG Srl for machining centres, and broaching and slotting equipment from Brighetti Meccanica, all manufacturers being based in northern Italy. Complementing this line up, the supplier is also sole agent for Sassatelli revolving centres and face drivers, Grippall bar pullers, Scheussler spindle tooling and shrink machines and Allmatic workholding solutions.

On show will be many examples of the high technology driven tooling solutions including gear hobbing, reciprocating broaching and gear skiving. Solutions cover around 40 different lathe brands, with over 11,000 variants of tooling available. Having more than 150 years of combined experience, the team of specialists from Machine Tool Supplies will be on hand to answer technical questions and assist with tooling requirements.

Whitehouse Machine Tools will launch in the UK the CubeBOX Pallet Pool PT-18 machine tool tending solution under its agency agreement with the Turkish manufacturer, Tezmaksan. The robotic cell will be connected to a Japanese-built Brother M300Xd1 30-taper, 5-axis mill-turn machining centre to illustrate how manufacturers can maximise their production output, raise productivity and reduce lead-times through long periods of unattended running.

The system is especially useful for automating production on a shop floor where space is limited and can handle up to 24 pallets, which are loaded and unloaded by a 6-axis robot. Not only that, but the unit also contains 16 extra cutters that can be exchanged by the robot in and out of the tool magazine, again fully automatically. Such an arrangement significantly reduces reliance on loading and unloading of parts and tools by hand and enables up to 24-hour unattended production.

Additionally, Whitehouse will promote Brother’s Speedio Blue Technology, which lowers greenhouse gas emissions at production sites. The optimally compact design of the machining centres reduces waste, resource utilisation and energy during parts machining.

Exhibiting for the first time, Compass Business Finance, will be urging showgoers to “think differently about finance” to get the best possible solutions, tailored to their own business requirements.

A fun highlight on its stand will be the Batak Reaction Game. People’s speed and reactions will be tested, with daily and weekly winners in line for a prize.

Whether companies will be looking to invest in new equipment, increase working capital, move premises, embark on a new project or even buy another company, they are on site there to help.

Mills CNC, the exclusive distributor in the UK and Ireland of machine tools from DN Solutions, Korea and Zayer, Spain, and a leading automation systems supplier to component manufacturers, will be showing a DN Solutions multi-tasking, large-bore, turn-mill lathe. The Fanuc-controlled Puma SMX 2100SB is a popular, proven machine equipped with twin 22 kW / 5,000 rpm spindles, a 12,000 rpm B-axis milling head, a 40-tool position ATC, a 12/24 position turret deploying driven tooling at up to 5,000 rpm and integrated thermal compensation.

The SMX 2100SB attracted considerable attention when it was exhibited at Mills’ open house and tooling company Seco’s Inspiration through Innovation event, both of which were held in October 2024. Tony Dale, Mills’ CEO commented, “This Puma turning centre can help component manufacturers revolutionise the efficiency of their processes and maximise their productivity and we look forward to showing visitors how it is achievable.”

XYZ Machine Tools will promote the rigidity, durability, thermal stability and superior machining performance of its machine tools, which are constructed with a Meehanite cast iron base. They are coupled with capable control systems, either ProtoTRAK or Siemens, and are ideal for prototype and low-volume production. A selection of machining centres and CNC lathes will be on the company’s two stands at the show, including the 65 LTY-S twin-spindle turning centre with live tooling and Y and C axes for single setup turning and milling of complex components. The lathe can produce parts up to 490 mm long and bar diameters up to 66 mm can be fed into the machine. There will be live demonstrations of this and other XYZ machines throughout the show.

In the metrology field, Hexagon Manufacturing Intelligence will explore its full suite of solutions for enhancing efficiency, accuracy and productivity across various manufacturing processes. The company will show its advanced metrology solutions, including precision measurement devices designed to optimise quality control in complex production environments. From portable measuring arms and laser trackers to cutting-edge handheld scanners, the metrology technology empowers manufacturers to achieve high standards and operational consistency.

Visitors will also take a firsthand look at Hexagon’s production software offerings designed to streamline manufacturing workflows. The solutions integrate seamlessly with the hardware on offer, providing data-driven insights that increase productivity and reduce lead-times. In addition, systems will be on display that enable rapid prototyping, simulation and end-to-end digital engineering for efficient product development. They allow users to refine designs and achieve better performance outcomes before products reach the production floor.

LK Metrology, a British co-ordinate measuring machine (CMM) manufacturer, will show an Altera C HA high-accuracy series model equipped with its new EcoAir function, an energy-saving device that automatically stops delivery of compressed air to the CMM after a period of inactivity, reducing consumption by up to 95% when the machine is idle. New also will be LK’s own CMM laser scanning probe, the SLK25 VIVID, and the company’s modular tool storage and change racks for tactile probes, laser scanners, extension bars and other sensor accessories.

There will be a third-generation LK Freedom arm, now supplied as standard with a 4.5 inch diameter mounting ring to allow the unit to sit on a larger base for increased stability and accuracy, rather than the previous 3.5 inch ring. Additionally, there will be a chance to experience LK’s new Interactive Virtual Reality showroom, featuring 10 CMMs running inspection programs.

A company spanning the areas of workholding and automation will be 1st Machine Tool Accessories, which will take two stands at the show. One will be devoted to the UK launch of long and short bar feeders with advanced anti-vibration technology, workpiece load/unload systems, hybrid automation arrangements and custom solutions manufactured by the German firm, Breuning IRCO. The modular, compact, robust equipment is suitable for automating CNC sliding-head and fixed-head turning centres, including multi-tasking lathes, and also mill-turn machining centres, rotary transfer machines and special purpose machine tools.

The second stand will feature other products sold under sole agency agreements with other overseas manufacturers. One is Japanese company Kitagawa, which produces standard and custom manual and power chucks, 4th and 5th axis rotary tables, robot grippers and machine vices. SINCO modular, zero-point clamping solutions from Slovenia can offer hundreds of zero points in one solution for ultimate flexibility when setting up workpieces. Chick quick-acting workholding solutions from the US provide rapid, secure clamping of single or multiple parts, prismatic or round. Additionally, Halter machine tool tending solutions and Darex drill sharpeners will be promoted.

Additive manufacturing will be prevalent. For example, Mark3D will be bringing its Markforged FX10 industrial 3D printer to the exhibition to demonstrate its FDM (fused deposition modelling) capabilities. Reliable, accurate and designed to produce strong components, the FX10 has more in common with machine tools than competitive printers. It is possible to 3D print jigs and fixtures overnight from a range of mechanically resilient materials.

By integrating carbon fibre, Kevlar and fibreglass, the machine creates composite parts that are stronger than aluminium. For components that require even greater strength, users are able to employ 17-4 PH and 316L stainless steel on the same machine and on the same day. FDM means no powder, resin or protective clothing. Its simple spool-off-spool-on material loading and automatic changeover allow the machine to work through the night without human intervention or complex settings.

Numerous subcontractors will be presenting their services. Altex Engineering, for example, will be there to promote its sheet metal fabrication and CNC machining capabilities, as well as its design services and re-engineering advice, which takes a product from initial concept through prototyping to full-scale production. CNC laser cutting, punching, metal forming, inserting, welding, stainless steel fabrication, powder coating, finishing and assembly all come under the company’s remit.

Ongoing investment in new plant, such as an L5 CNC fibre laser cutting machine and a P2 panel bender from Salvagnini, plus a Trumpf TrueArc automated welding robot, ensures that Altex remains at the forefront of technology. Its most recent investment is a six-tonne gantry crane, facilitating the handling of large fabrications. Based in Calne, Wiltshire, the company is certified to ISO9001-2015 and supplies its cost-effective manufactured items throughout the UK and worldwide.

Over the three days, visitors will be able to take advantage of an extensive programme of free-to-attend technical seminars, with a particular focus on the technical, managerial and environmental issues facing manufacturers today. Car parking at the Farnborough site and the regular bus service that runs between the two local railway stations and the showground are also complimentary.