CYTEC’s clamping systems continue to drive efficiency in automotive manufacturing

CYTEC says it is continuing to set the benchmark in industrial automation with the company’s range of self-locking clamping systems, engineered for reliability, precision and adapatability in universal joining and mounting processes.

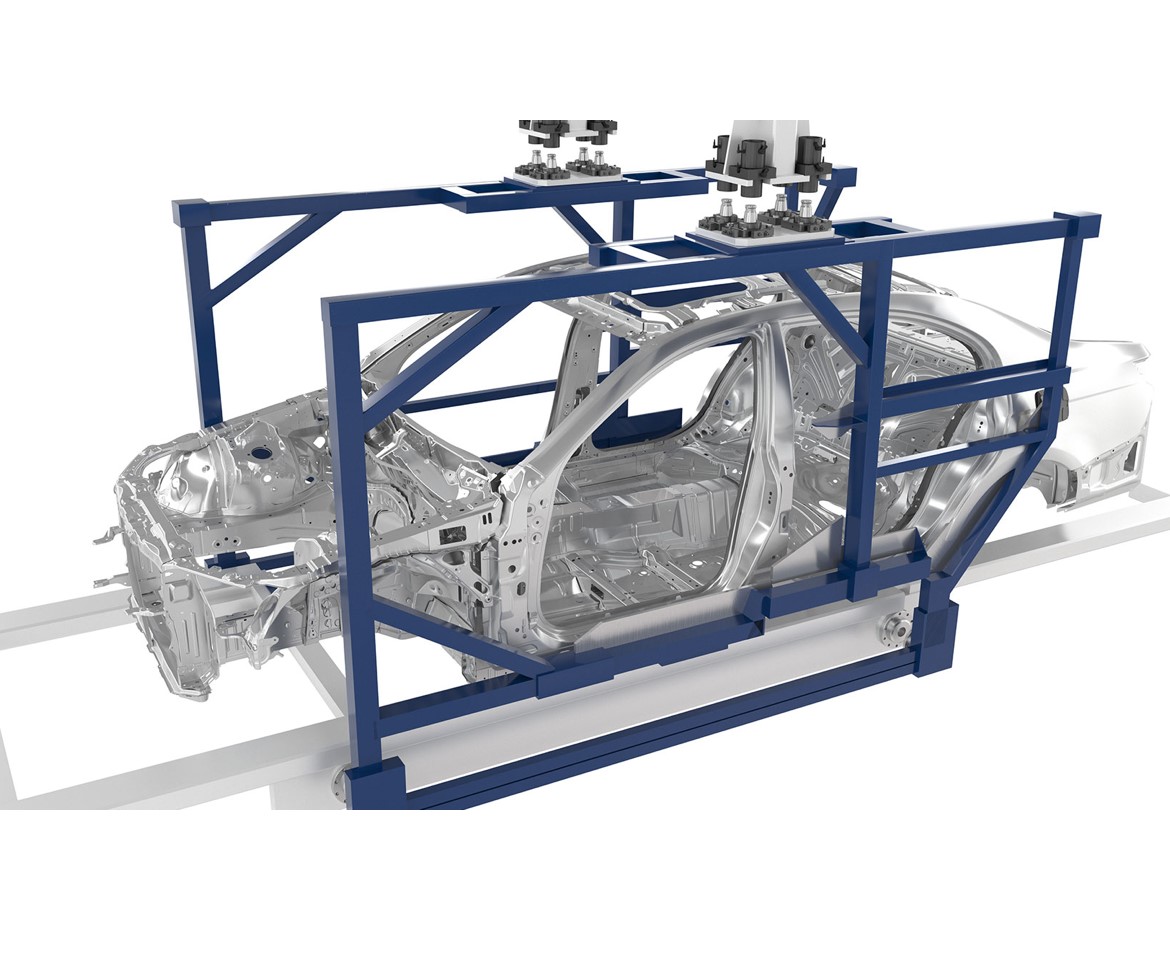

The CYTEC CyTab clamping system has seen widespread adoption in automated welding and assembly lines throughout the automotive sector. In use at leading vehicle manufacturers, CYTEC reports that CyTab systems consistently deliver safe, flexible and cost-effective production performance, helping streamline operations while meeting ever-evolving industry standards.

The clamping systems are engineered to be 100% failsafe, offering high clamping and holding forces, repetition accuracy, and secure self-locking in the clamped position. They are designed to perform reliably across a wide range of automotive applications, from framing units and gripper systems to press line tooling.

In addition to performance, CYTEC ensures that accessories and spare parts are readily available, supporting long-term operational continuity and ease of maintenance.

For manufacturers seeking robust, precision-engineered clamping solutions, CYTEC invites industry professionals to connect with its team and explore how these systems can elevate production capabilities.