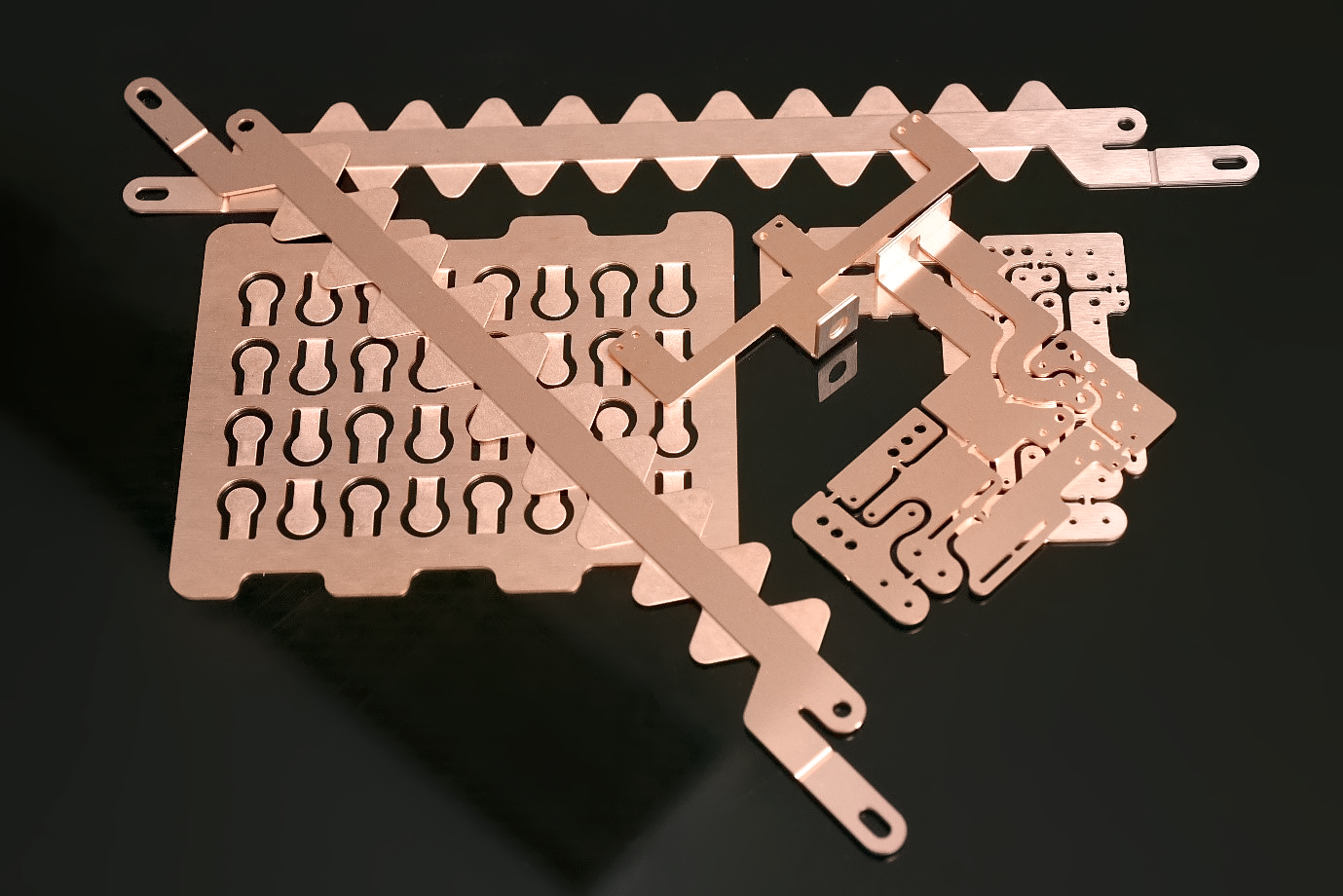

Chemical etching from ACE at Southern Manufacturing

Based in Telford, Advanced Chemical Etching (ACE) uses innovative chemical etching processes to manufacture precision metal components at volume, providing today’s product development engineers with greater design flexibility and shorter lead-times. It has seen volumes in the automotive and aerospace sectors increase rapidly, alongside new opportunities for its titanium, copper and aluminium etching expertise in the race for electrification and hydrogen fuel cell systems. The process lends itself to battery interconnect and fuel cell component manufacture, important to the development of energy management in existing and future electric vehicles and alternative fuel systems, as will be showcased on the company’s stand.

ACE also specialises in the development of prototypes, pre-production and volume manufacture for customers in the electronics, medical, telecoms and renewables sectors. The scope of its activities includes anything from safety critical components for aircraft and F1 cars to meshes, electronic connectors and heat exchangers. It works to exacting tolerances and can manufacture components in stainless steel, nickel alloys, copper, beryllium copper, phosphor bronze, brass and, thanks to ground-breaking new processes, aluminium, molybdenum, titanium, nitinol and elgiloy.