Ceetak builds sustainable vacuum sealer for Johnson Matthey

A reliable, safe and sustainable vacuum sealer built by Ceetak Heat Sealing for global technology giant Johnson Matthey was the result of collaboration and a shared passion for sustainable and efficient engineering.

Johnson Matthey’s mission is to innovate and improve the way it operates with the highest safety standards for its people and the protection of the planet. The technology giant approached Ceetak with a simple brief: upgrade the company’s existing vacuum sealer, make it more user friendly and increase efficiency.

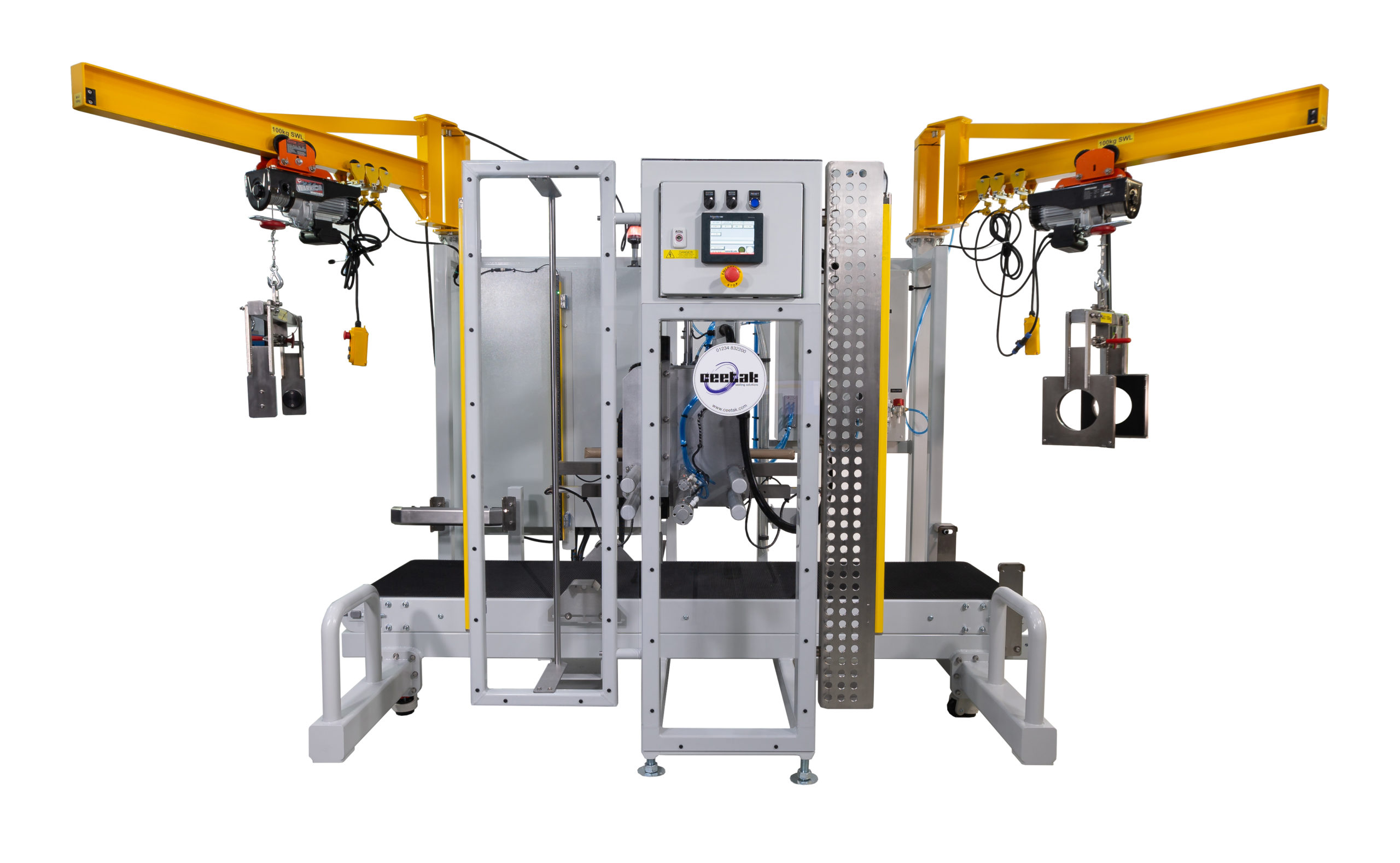

The existing machine was a 100% manually operated vacuum sealer for heavy and high value products contained in a robust laminate material bag. Operator ease for handling and loading was a further priority, while Ceetak’s brief also included building a machine that one person can manage (a reduction from two operators).

The vision was a machine whereby an operator placed the bagged product on a conveyor to be passed through for vacuuming and sealing. To accelerate efficiency, Ceetak proposed installing electric and adjustable hoists to lift and move the sealed package.

Ceetak’s ImPulse Heat (IPH) sealing system was confirmed as the optimal solution. The sealing bars create leak-proof seals both around and over variations in material thickness. Additionally, they compress and adapt to the contours of the material, ensuring a reliable seal, even when creases form during the vacuuming process.

Richard Piper, Mechanical Engineering Lead from Johnson Matthey, says: “The machine has already improved operator output and efficiency. It’s extremely well received among the team because it’s safer and easier to use than our old machine.”