AXILE Gives ETG Customers Lessons in the ART of Industry 4.0

The Engineering Technology Group (ETG) has always been revered for the technology behind its industry-leading brands and the respective solutions available. However, with the arrival of the AXILE brand, ETG has in its presence a brand that takes Industry 4.0 and digitalisation to new levels for its customer base.

Since announcing its technology partnership with AXILE, ETG has sold several high-end 5-axis machine tools – what has lit the imagination for these customers is not just the potential of the machine tools, but also the innovation embedded within the digital platform.

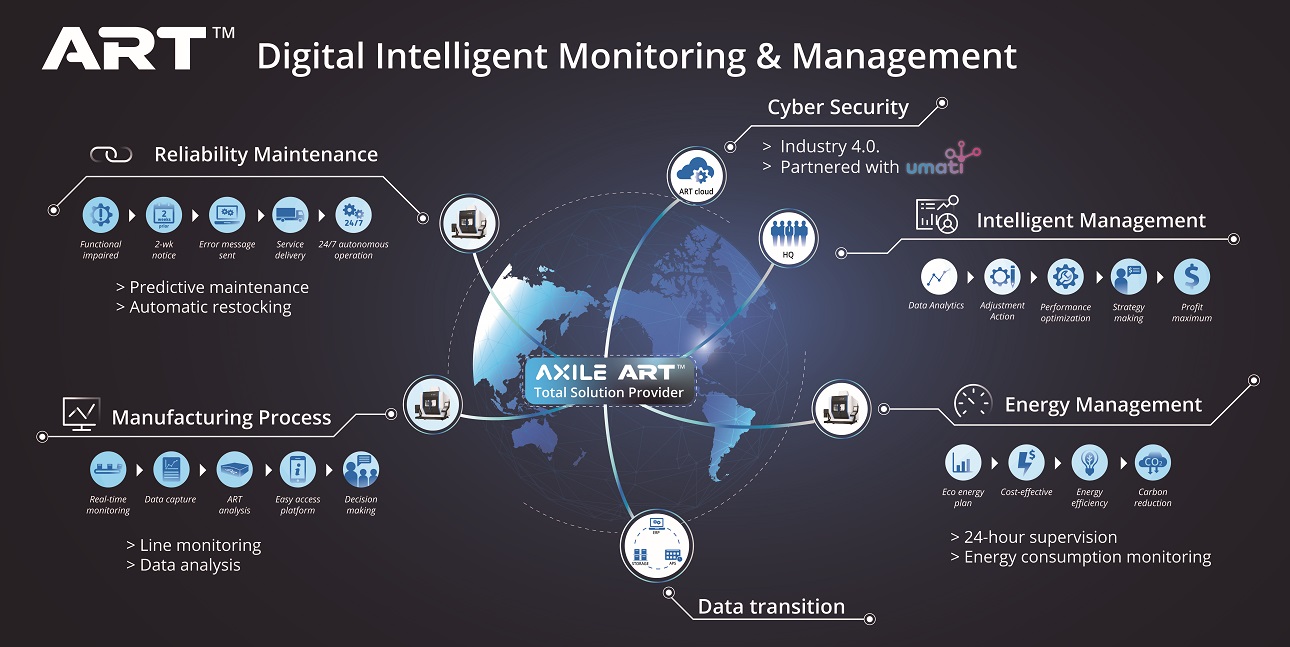

As a machine tools builder with a solid digital management background, AXILE understands the need to integrate environmental and economic aspects into its operations. Therefore, it has developed the ART™ system to focus on improving operational performance and the energy efficiency of its products. To deliver agile smart machining and that all-important competitive edge, ART™ enables 24/7 automated production and allows operators to digitally manage, plan and strategise through comprehensive data analysis.

ART™ monitors all the wearing components, energy consumption and fluids such as lubricant and coolant to supply real-time status updates on the machine and its components and to pre-empt future issues. AXILE’s ART™ system empowers manufacturers to make informed decisions, optimising production and greatly improving efficiency.

In a nutshell, ART™ has four core functions. This includes Reliability Maintenance (RM) where ART™ delivers machine components diagnosis, machine lifetime estimation, and consumable supplies monitoring to prevent machine failure and eliminate unplanned downtime. The next core function is the Manufacturing Process (MP) intelligent monitoring system that offers transparency. Data collection and analytics deliver critical information on the health and production schedule of each machine and vital internal components. The next critical aspect is the Energy Management (EM) system that enables manufacturers to monitor power consumption to identify ways to maximise energy efficiency and reduce expenditure. The fourth pillar is the Intelligent Management (IM) feature which provides analytic information for managers to understand the machine’s performance and take immediate actions to optimise the machine’s capability.

The ART™ technology adapts OPC UA, a data exchange communication standard developed for Industry 4.0 applications to secure the framework of industrial inter-operability. It offers the most suitable conditions to adopt digitalisation, monitor and manage entire operations. The proprietary monitors and analysers developed by AXILE are the critical key to allowing ART to achieve the mission of collecting, analysing, and presenting valuable data. It uses mechatronics functions to watch the entire system’s wearing components and determine the working status.

Preventative Maintenance

The wearing of the mechanical components presents a significant limitation to machining productivity. There is a close relationship between the tool life, cutting speed and feed, but it’s not always easy to predict. The ART proprietary technology was developed to pick up signals accurately and analyse the critical components during machining, such as linear guideways, ball screws, bearings, coolant, hydraulic and pneumatic devices and chip conveyors.

With the analytic data, component lifetime can be predicted more accurately. Therefore, managers can arrange maintenance services and restocking of components to ensure operations are always on track. The analysers can also help raise issues through real-time monitoring of the wearing components.

Energy Efficiency

As stated by CECIMO, the amount of energy supplied to a machine tool is not an adequate indicator of its energy efficiency. Only energy consumption during use is a significant indicator. It must also be considered against the number of workpieces produced, their shape, quality, accuracy and other relevant factors following ISO: 14955 evaluation. Through the ART proprietary analyser, energy consumption during various applications and across components is collected. The analytic power consumption data allows managers to understand daily energy performance.

Strategic Decision Making

The ultimate purpose of the proprietary monitors is to gather all the required raw data and provide analytic information for engineers to make operational management more intelligent and sustainable. With digitalisation, customers can now directly access real-time machine data and production process information daily, weekly, and monthly, even retrieving the synchronised information worldwide using PC and mobile. Accurate information management allows managers to understand machine performance and take immediate actions – optimising machine capability, arranging maintenance, and making better future investment plans – regardless of location. There is of course far more to this system than meets the eye – there are reasons why the AXILE brand is selling so fast. Isn’t it time that you found out more?