Automating AM – Finding the balance

Since the 19th century, the power loom has enabled significant improvements in textile and fabric production. Novel technologies like non-stop shuttle changing devices and thread replenishment systems made quality cloth available to a mass market. Developing automation in additive manufacturing (AM) can have similar benefits and one way to reduce cost per part is to optimise in-machine processes, says David Beeby, New Product Development Manager at global engineering technologies company, Renishaw.

Across the manufacturing industry, automation has helped enable low-cost, high-volume production by reducing operator input, improving part consistency and increasing productivity. In AM too, automation can lower cost per part and improve return on investment (ROI) for users, but the specific processes that are most worthy of automation will depend on how a manufacturer uses AM technology.

Automating around the system

Production lines in a modern factory are increasingly automated, with an increasing number of fully automated ‘lights out’ factories in operation. These automated lines often use robots to move parts between machines, freeing human technicians to move away from repetitive actions and focus more on critical tasks such as quality control. AM is a relatively new technology and was initially used for rapid prototyping, reducing the need to automate. However, as more manufacturers begin using AM as a mass production tool, businesses must consider how to implement levels of automation in a way that preserve the technology’s benefits, such as design freedom and high efficiency, to generate profit.

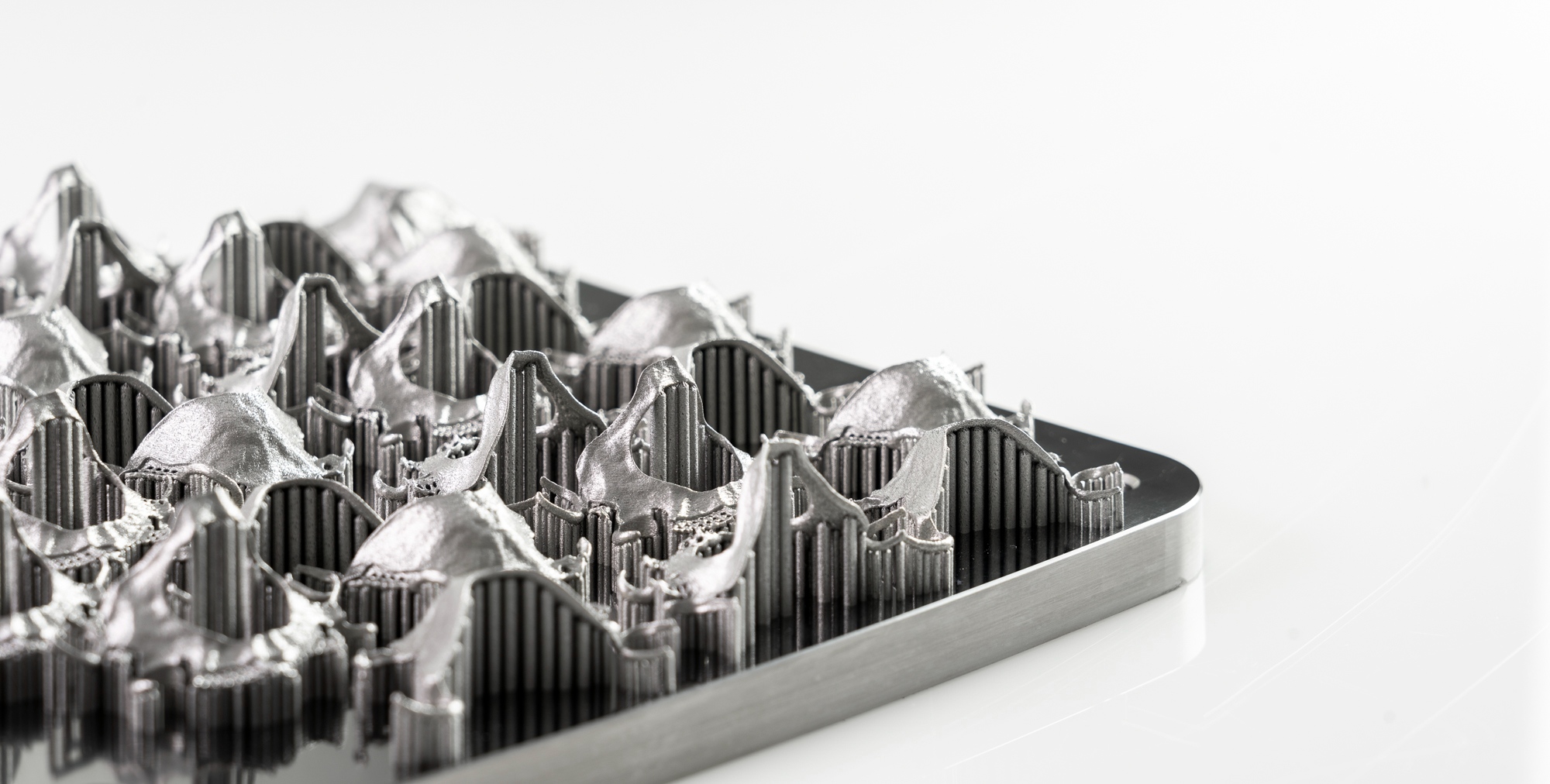

For instance, consider a between-machine feature that automatically moves complete components from the build plate to a storage area once a run is finished. This could eliminate a labour bottleneck in high volume applications where builds finish throughout the day and night but cutting the parts from the build plate might create a swarf and coolant slurry within the build chamber. The machine would then require additional systems to prevent the slurry from contaminating the build chamber or feedstock, impacting the next build.

Introducing this additional complexity to the machine would increase its running costs and might thereby make it unsuitable for lower volume applications, or negate the benefits gained from reducing manual input in the first place. For example, an organisation using AM to print one large, complex component over several days, would benefit less from automated part removal than a manufacturer producing multiple components at a time in a build lasting twenty minutes.

In addition, integrating more between-machine or peripheral systems, such as automated component support removal, risks duplicating function on a factory floor. If support removal takes one tenth of the time of the actual build, a factory would only need one support removal machine per ten build installations — any more would waste valuable floor space and lock up capital, so having one on each build module would be redundant.

Automating AM systems

For manufacturers that do want to increase AM productivity, automating in-machine processes is one of the most promising opportunities for growth. For example, the automatic powder recycling and conditioning system featured in Renishaw’s RenAM 500 series of metal AM systems can greatly reduce variability in feedstock condition and keep peripheral parameters more stable.

The system also saves significant time by reducing initial set-up and eliminating the need to externally prepare feedstock and transport it to the machine. Pouring virgin powder into each machine is workable in some cases, but in a factory containing dozens of systems and producing thousands of components per day, it could create a production bottleneck.

Another example of in-machine automation is Renishaw’s new TEMPUS™ technology, which is retrofittable to all current RenAM 500 systems. TEMPUS™ technology is a new scanning algorithm that delivers a substantial increase in AM productivity without compromising on part quality. It allows the system lasers to fire as the powder recoater is moving, removing up to nine seconds of build time from every layer. With builds frequently containing thousands of layers, this can reduce total build times by tens of hours.

The future

As loom technology matured and production efficiencies increased, attention naturally shifted towards optimising downstream processes, leading to the development of automated material handling systems. Likewise, manufacturers at the beginning of their AM journey might benefit from focussing on in-machine automation before between-machine automation.