Automated mill-turn cell halves cutting cycles and operations

British designer and manufacturer of bedpan macerators for healthcare institutions as well as sewage treatment systems for municipal water companies, Haigh Engineering (www.haigh.co.uk), has upgraded the capacity on its shop floor in Ross-on-Wye with the installation of a German-built, 5-axis Hermle C 42 UMT prismatic machining cell with turning capability.

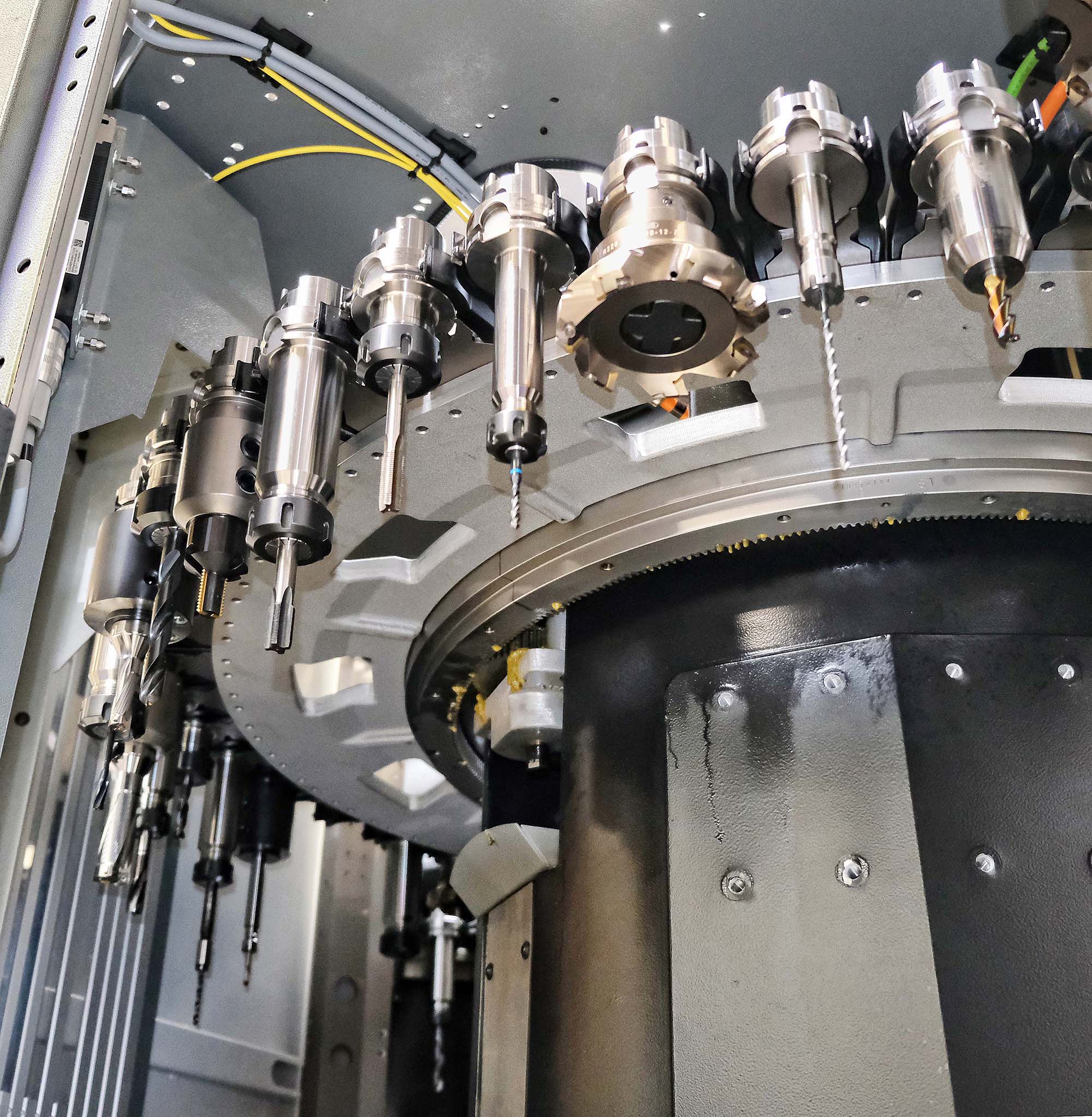

Included are a multi-level tool magazine for holding 50 tools in addition to the standard 42 tools, making a total of 92, and a six-pallet storage system served by a 3-axis HS Flex Heavy robot for automatically transferring pallets with a maximum capacity of 1,200kg into the working area and returning them after components have been machined. The cell was delivered in September 2022 by Kingsbury.

In 2021, Haigh Engineering identified the opportunity to upgrade. After considerable research, three suppliers were shortlisted based on their expertise within the required metal cutting applications. Additionally, Mr Phillips and machine shop manager Jeremy Allen visited a business on the South coast that has extensive experience with Hermle equipment, including a C 42 UMT. As well as the machine being the optimal size for the planned work, the integrated 6-pallet robotic loading system with the option to extend it, the Heidenhain control and the reputation of Kingsbury for UK-based support all swayed the decision.

Kingsbury provided Haigh Engineering with advice and contacts through the installation process. Even though the Hermle C 42 needed to be lifted through Haigh’s factory roof, no small exercise, the project was completed within target dates, with successful commissioning and operator training provided by the Kingsbury team.

A majority of the throughput involves machining of castings, mainly iron but also stainless steel and aluminium, ranging in size from 400 mm high by 600 mm square down to 150 mm diameter by 150 mm long. Some weigh as much as 250 kg.

While the machine is currently attended full time, as the setters optimise usage, the intention is to set up multiple parts on the six pallets and run the system lights-out. Some unattended machining is already achieved at the end of each day shift by loading a raw casting that requires 60 minutes or more of metal cutting time, allowing production to continue past normal working hours.

Before the arrival of the Hermle cell, the production process for most components when the former machining centres were in use involved two prismatic machining operations on either of them, preceded by two turning operations on lathes. With the provision of a torque table on the C 42 UMT, turning is now done in-cycle, so parts come off complete after just two operations. Overall, actual metal cutting time is about half compared with the equivalent machining cycles on the older mills. Moreover, only one inversion of the component at the HS Flex Heavy set-up station is required, rather than the three subsequent re-handlings as previously, saving even more time.

The pallet store is controlled and managed by HACS, Hermle’s automation control system, which enables smart order management via the touch screen. It will be linked to Haigh Engineering’s MRP system, as with other machine tools on site. The connectivity allows production orders to be sent directly to the machine, providing improved job sequencing and optimising output. The resulting availability of more and better data, especially of machine utilisation, will continue to enhance the manufacturer’s operational efficiency.