Automated mill-turn cell from Brother is optimal for subcontractor’s unattended production

A shortage of skilled engineers and a desire to continue with single day shift operation over an existing pattern of a four-day working week have all played a part over the past five years in prompting JWA CNC to research the best way to automate its production. It led in early March 2023 to the purchase of a Brother 30-taper M200X3 mill-turn centre with integrated BV7 component stocker and robotic handling. Installed in one of the subcontractor’s two factory units in Leicester, the turnkey cell was supplied by the Japanese manufacturer’s sole sales and service agent for the UK and Ireland, Whitehouse Machine Tools, Kenilworth.

Currently serving mainly the aerospace and defence industries as well as the emerging hydrogen fuel cell sector, JWA CNC produces a lot of prismatically machined components in mainly non-ferrous materials such as aluminium, stainless steel, copper, brass and plastics, often to single-figure micron tolerances. They are required in relatively limited quantities in the range 30- to 100-off, sometimes fewer if they are for R&D projects, so the company needs automated production systems that are fast to change over to a new batch run.

Pete Wood, Operations Director at JWA CNC said, “Automation of lathes is easy using bar magazines and we have numerous such turning cells on our shop floor. However, autonomous production of milled components is more problematic because of the high diversity of shapes and small batch quantities.

“The typical selling price of prismatic parts going through our factory does not justify the purchase of a machining centre with a pallet storage and retrieval system, as they tend to be expensive and are also space-hungry. So robotic handling of the components themselves into and out of the machining area was a necessity.”

An early move towards this type of automation to compete with manufacturers in low-wage countries was made three years ago when the company decided to add a 6-axis cobot to a 4-axis BT40 machining centre on the shop floor. Operating with a single tray of parts, it works well unattended but has a couple of drawbacks. First, it is relatively slow to exchange a finish machined component for a new billet, taking around 3.5 minutes; and second, the automation takes up a lot of space.

In contrast, the Brother system avoids both of these negatives by executing component exchange in well under half a minute and by compressing the machining centre complete with its automation into a 3.5 metre x 4.1 metre footprint, only a little larger than that occupied by the cobot alone. With space at a premium at the Leicester facility, the compactness of the new cell is an important plus-point.

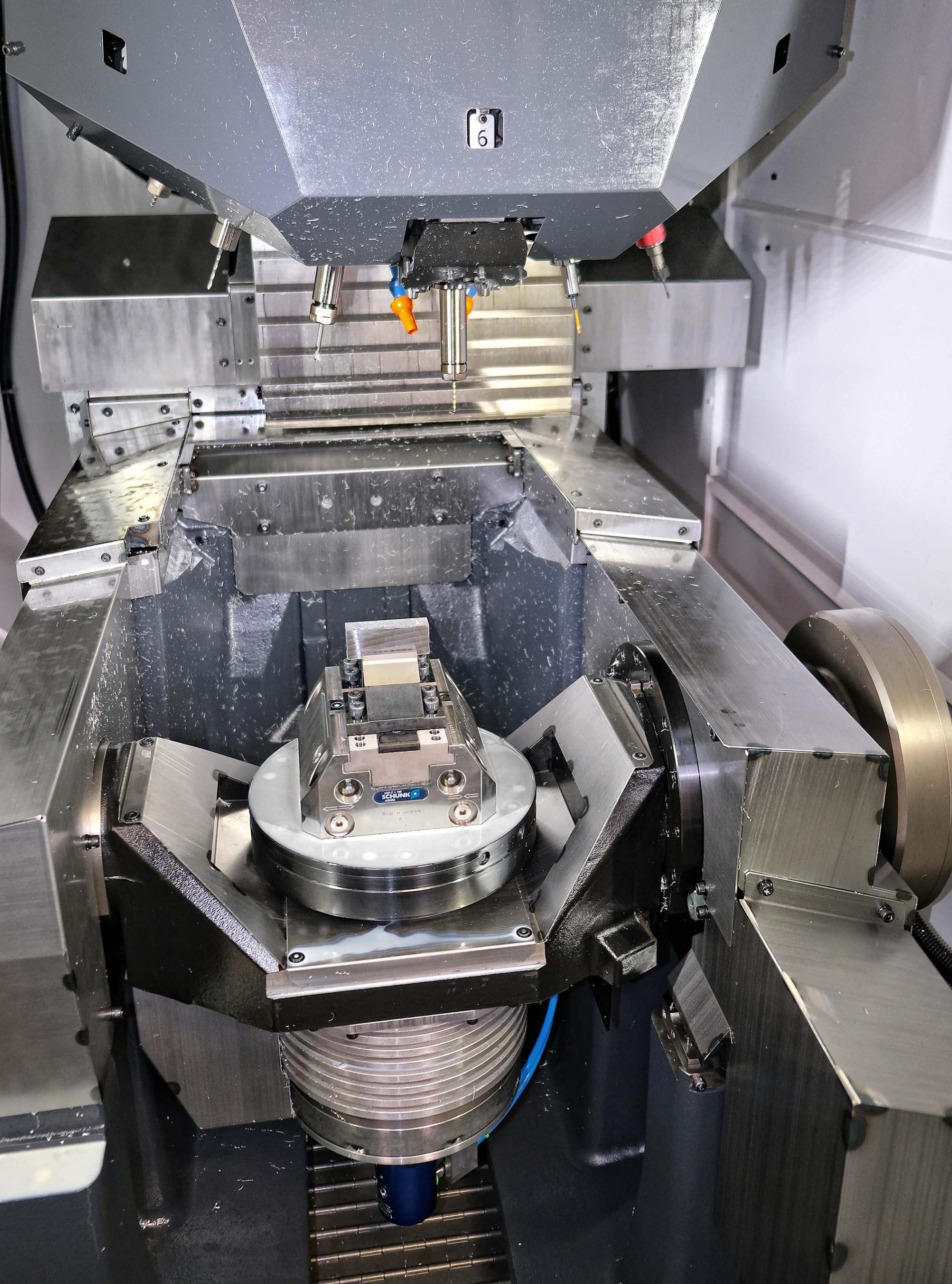

The integral robot effecting load/unload of the individual workpieces has four CNC axes, three rotational and one linear into and out of the machine via an automatic door. It carries twin grippers with the end effectors opposed to each other at 180 degrees. They load and unload parts into and out of a pneumatically-actuated fixture on the rotary table mounted on a trunnion that swivels from +120 to -30 degrees. According to JWA CNC’s technical director Tim Shillabeer, the fact that a 4-axis rather than a 6-axis robot performs component transfer reduces set-up time and gives him confidence in a high level of ongoing operational reliability.

Three notable aspects of the Brother M200X3 are that it is the third BT30 machining centre in the factory but the first with a face-and-taper spindle; the second 5-axis model on site; and the only milling centre with a torque table capable of turning components in the same set-up. Several parts produced by JWA CNC require pre-turning before prismatic machining, so there will be a saving by performing both operations on the Brother, especially if the subsequent 5-axis milling and drilling allows parts to exit the machine in fewer set-ups, or perhaps even one.

Another advantage of 30-taper machining centres is that they are highly productive. The Brother machine, for example, has 50 m/min linear rapids and fast rotary motions that reposition a part for the next cut while the 1.4-second chip-to-chip tool change is taking place, avoiding undue idle time. The 22 cutters in the tool magazine are deployed by the dynamic, 16,000 rpm face-and-taper contact spindle that combines speed with precision.

An often overlooked additional benefit of a 30-taper machine over a 40-taper model is that, due to the former’s high productivity, a typical part is produced faster and therefore with less energy. Combined with numerous efficiency measures within the machine, such as reduced air consumption, hybrid drive motors with power regeneration, high efficiency pumps and auto-off functions, it results in less power being consumed per part manufactured.

Brother claims an overall reduction in energy consumption of around 80% compared with using a 40-taper machine to produce any given component. With the M200X3 installation being so recent, JWA CNC is unable to substantiate this saving. What it can say, however, is that with electricity costs having nearly quadrupled in the first six months of 2023, every little helps.