At the C.O.R.E. of Precision Grinding

Given industry’s growing use of the internet of things (IoT) and the emergence of smart factories, potential machine tool customers are increasingly looking to purchase cutting-edge manufacturing aids with ‘smart’ controls and enhanced connectivity capabilities.

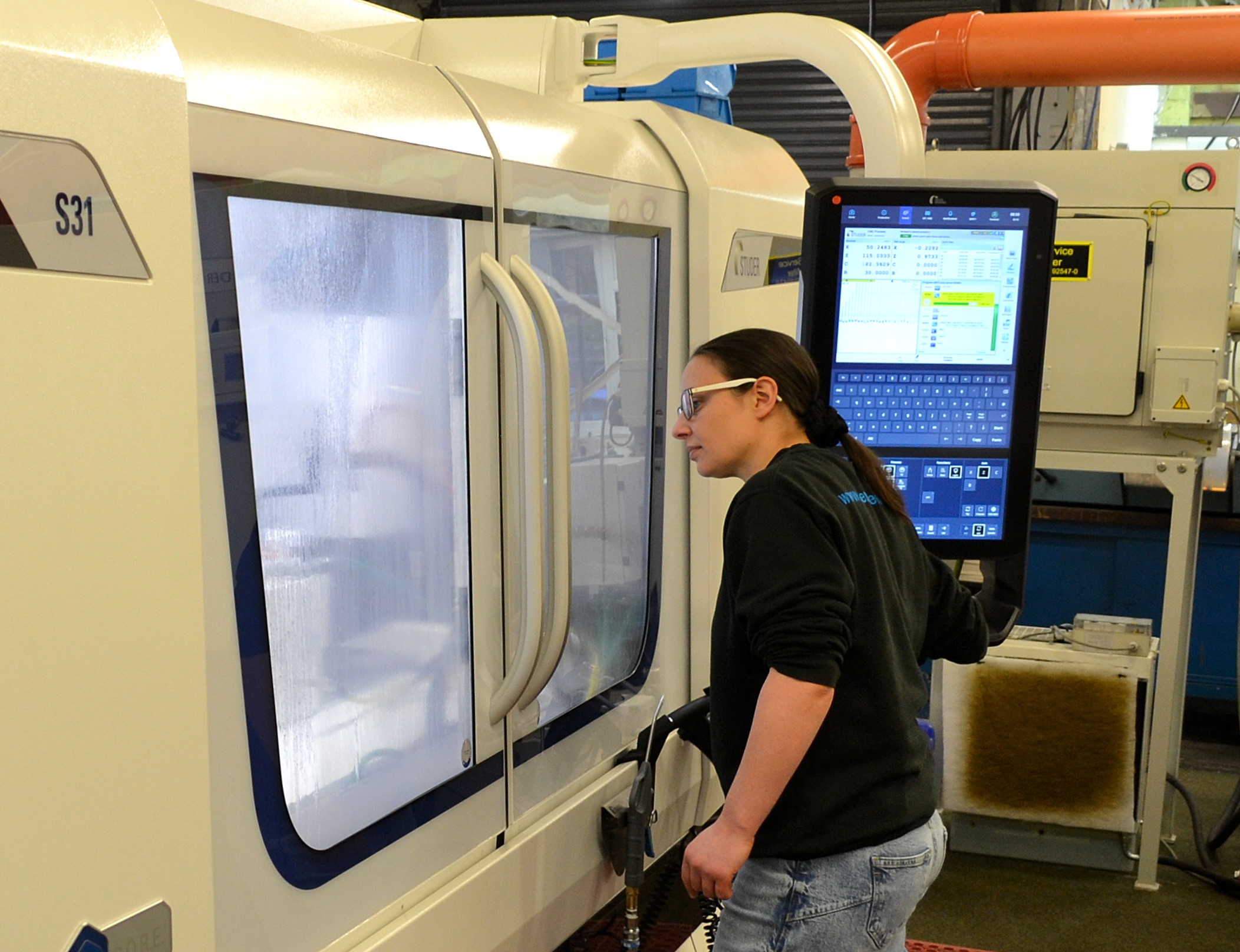

One such progressive company is West Byfleet, Surrey based T&G Engineering. In accordance with the business’ policies of remaining at the cutting-edge of developments within the field of machine tools and of embracing modern data systems, T&G Engineering recently installed the first Studer S31 universal cylindrical grinding machine sold in the UK featuring the latest UNITED GRINDING C.O.R.E. operating system.

T&G Engineering Director Tong Smyth comments. “T&G Engineering’s highly skilled workforce have access to a wide range of state of the art machine tools and advanced systems enabling the efficient production of complex components with extremely close tolerances. Our comprehensive plant list and in-house knowledge means that our customers regard us as a ‘one stop shop for their precision machining needs, this has allowed us to penetrate many technically challenging market sectors. T&G Engineering’s specialist area is the subcontract machining of complex components and assemblies used for demanding applications within harsh environments.

“We have a wide-ranging in-house grinding provision and when tasked with achieving the most demanding levels of precision and surface finish, we use our collection of advanced Studer universal CNC grinding machines. Our first Studer machine was installed more than 20 years ago, so good was, and still is the performance of the machine we have since added several other Studer grinders, each equipped to the highest of specifications. In addition to achieving our demanding levels of dimensional precision and surface finish, our Studer machines are extremely efficient and have proven to be trouble free.

“Our recently installed Studer S31 universal cylindrical grinding machine was ordered because of the ever increasing amount of high-precision cylindrical grinding work we need to perform. As we have done in the past, before our latest Studer purchase we liaised closely with Peter Harding, the Managing Director of Advanced Grinding Supplies, the exclusive Studer agent in the South of England and Wales. This co-operation ensured that we specified our new Studer machine to suit our exacting requirements.

“In keeping with our policy of ordering our machine tools with the latest technology that will aid our efficiency levels, our new Studer grinder uses UNITED GRINDING’s latest C.O.R.E. operating system. C.O.R.E. has now been incorporated into our in-house digital communication and production systems and has further improved our programming and grinding efficiency levels.”

Thanks to the uniform C.O.R.E. software architecture, exchanging data between UNITED GRINDING machines is now effortless. The integrated system’s universal machine technology interface (umati) can also be used to communicate with third-party systems and provides access to UNITED GRINDING Digital Solutions™ products directly on the machine without requiring the installation of additional hardware. C.O.R.E. not only establishes the technical foundation for these advantages and other IoT and data applications, it also forms the basis of a

Peter Harding concluded. ”All at Advanced Grinding Supplies are proud to have worked closely with T&G Engineering for many years. Knowing the level of complexity and the demanding nature of the parts to be ground we were able to configure the company’s new Studer S31 to meet these challenging requirements.”