Alloyed CEO Michael Holmes says advanced manufacturing can make the UK an industrial powerhouse again

Traditional manufacturing has been in decline in the UK for a while now. In the sector as a whole, employment levels have fallen for three years in a row, while factory output is expected to shrink by 0.6% this year. These figures are particularly disappointing given manufacturing is one sector where Britain was once world-leading. Indeed, last year was the first time since the industrial revolution that the UK fell out of the top 10 list of manufacturing nations.

All is not lost, however. While global demand may have evolved beyond the UK’s industrial roots and manufacturing now accounts for a smaller percentage of the UK economy than 30 years ago, there are other areas which have remained more consistent.

The UK still has a reputation for academic and research excellence. And it had a highly skilled workforce of science and engineering graduates. The door on traditional manufacturing might be closing. But in advanced manufacturing, another door of high growth potential is opening.

The opportunity

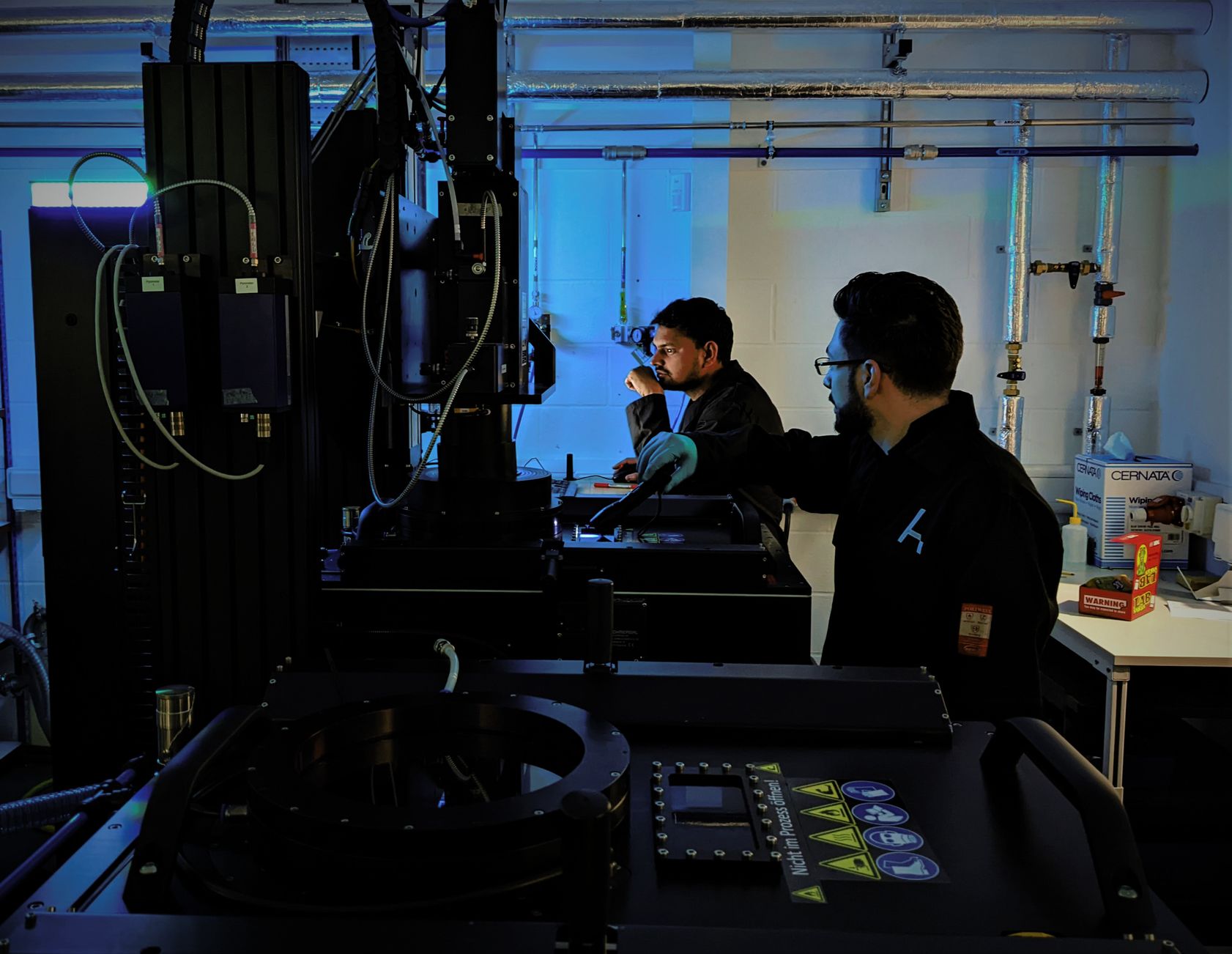

Advanced manufacturing is already reshaping the global economic landscape. From AI-powered design to digital twins and smart factories, global demand for technological innovation is only growing.

In the UK, the potential is enormous. Last year, the advanced manufacturing sector turned over £117.1 billion and received £15.4 billion of investment. It is growing at 2.0% per year, while some sub-verticals are performing even better.

The metal additive manufacturing industry, for example, grew by around 15%, far outperforming traditional manufacturing sectors and demonstrating resilience in challenging conditions.

With the Government urgently seeking sectors of the economy capable of driving immediate progress on its highly prized ‘growth agenda’, advanced manufacturing can’t be overlooked.

There’s an innovation argument of course. A renewed focus on putting innovative products at the heart of the UK economy again would bring with it investment, business support and skilled employees – all of which are beneficial for growth.

Seizing the moment

But there’s a real argument for why advanced manufacturing specifically should be the sector to drive this growth right now.

On an international level, there is a need to reduce carbon emissions – and quickly. In the race to achieve goals on decarbonisation, manufacturers need new materials. Particularly in polluting industries like aviation and the automotive sector, demand for lighter, cleverer, more locally sourced materials is booming.

The search is also on for metals capable of withstanding higher temperatures (and therefore more efficient) is growing rapidly.

As well as decarbonisation, the other trend driving demand in advanced manufacturing is miniaturisation. Electronics companies are looking to fit more computing power into increasingly smaller forms – which need to be supported by highly specialised metal structures. Think wearable tech that can handle ever more powerful AI.

These are not fleeting trends, but fundamental shifts that are defining the products and innovations of tomorrow’s economy. And advanced manufacturing is the driving force capable of delivering them to market at the speed and scale needed.

What’s more, the use of ever more sophisticated 3D printing technology offers significant advantages for advanced manufacturing. Particularly in a hostile international trading environment – where tariffs on exported goods can be introduced almost at a moment’s notice – the ability to be able to build world-leading innovations domestically is invaluable.

Not only this, but material waste and transportation emissions are reduced, production costs are lowered, and highly customisable and complex designs can be developed in a much shorter time frame.

The UK’s unique advantage

With the UK’s rich heritage of engineering excellence and its highly skilled workforce, the foundations for the development of world-leading advanced manufacturing are already in place.

A strong focus on high-value sectors such as aerospace, automotive and pharmaceuticals, means that the UK’s engineering talent is already adept in the environments where advanced manufacturing techniques can offer a competitive edge through greater efficiency, customisation and sustainability.

The UK’s world-leading research institutions also strengthen its position in this field. Investment into university spinouts has grown 240% in 10 years, with world class engineering departments at the likes of the University of Oxford leading groundbreaking research in areas such as additive manufacturing, robotics and materials science, often in collaboration with industry partners.

Indeed, the focus of Oxford and other leading institutions on bridging academic excellence with industrial application means that the UK is well stocked with a steady pipeline of highly qualified engineers equipped with the theoretical knowledge and practical skills needed to drive forwards innovation in additive manufacturing.

What needs to happen

Now is the moment for the government, private sector and academic institutions to work together to cement the UK’s world leading position in advanced manufacturing.

This unique window of opportunity won’t last forever – the UK has already been surpassed in the manufacturing of key innovations, such as semiconductors. But in areas of advanced manufacturing like additive metals, there is still potential to be world leading.

One area where the Government can act decisively is strategic procurement. The ‘significant’ increase in Ministry of Defence investment in novel technologies, including dual-use, was an encouraging takeaway from March’s Spring Statement. And the fact that the department’s first ever advanced manufacturing strategy followed days afterwards is a sign that the Government is starting to understand its potential. More commitments like this will be important for creating demand, de-risking innovation and supporting the scaling of cutting-edge manufacturing.

Seizing this moment for the UK’s advanced manufacturing sector will require bold investments in R&D, infrastructure and talent. As well as this, it’s vital that partnerships between industry and academia continue to be supported to ensure that the next generation of engineers is both trained in the latest technologies and also empowered to push the boundaries of innovation.