Eight principals of Advanced Grinding Solutions set to show at EMO 2025

As always, the principals of UK-based Advanced Grinding Solutions are set to make a strong presence at EMO, which this year takes place on 22-26 September in Hanover, Germany. However, for the first time, all eight are conveniently in the same Hall – Hall 11.

Tschudin is highlighting the use of automation on its range of centerless grinding machines (photo above). The company is showing two machines on Stand D38 in Hall 11: the compact Tschudin Cube 350 machine and the larger Tschudin Proline 400 machine. Loading and unloading is particularly fast and easy on the Tschudin machines thanks to the patented W-axis whereby the work-rest blade is mounted on its own CNC axis and slides out of the working zone for component exchange.

Nova – a manufacturer of high-performance CNC machines for internal, external and combined grinding applications (with a particular focus on the bearing industry) – can be found in Hall 11 on Stand E82. The company says its machines are renowned for precision, speed and uptime, featuring easy access for quick changeovers and maintenance. Flexible work-holding options, including roller/shoe, magnetic/shoe and chucking systems, accommodate a wide range of part geometries and materials.

Comat, whose Superfiltration systems filter used cutting oil to a better-than-new standard, are on Stand F46 in Hall 11. Specialists will be on hand to discuss the company’s wide range of options, from compact stand-alone filter systems to the largest centralised solutions.

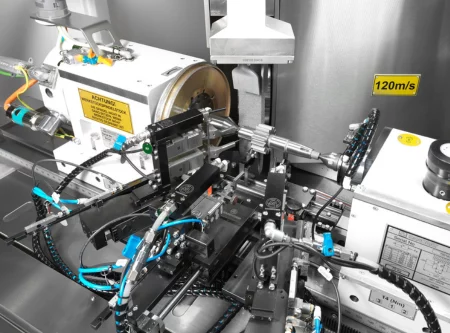

Danobat, which consists of 3 renowned brands – Danobat, Overbeck and Hembrug – is located on Stand F60 in Hall 11. The Danobat brand is known for its custom-built precision grinding and machining solutions (photo below) as used in the aerospace, railway, automotive and other industries. Overbeck has specialised in precision ID, face, radius, and OD grinding of hard materials for close to 100 years, while Hembrug focuses on hard turning and turning/grinding machines. At EMO, Danobat will unveil new grinding models ― all designed for greater flexibility, tighter tolerances, improved reliability, reduced footprint and automation. Staying true to its innovative spirit, Danobat will also present its latest robotic solutions that optimise existing processes and open new production possibilities. According to Danobat, the most accurate, stiff and stable CNC robot on the market is going to perform real-time machining at EMO.

Wick AG, which manufactures a range of deburring machines for Magnetfinish, will be using EMO to showcase the very latest Magnetfinish deburring machine for cutting tools of all kinds. The company has developed a strong reputation for designing and producing customised robot cells tailored to diverse industrial applications. Processes such as checking and measuring, washing, drying, laser marking, deburring, and assembly can all be included within a turnkey automated solution. Wick/Magnetfinish will be present in Hall 11 on Stand E89.

Gerber has been specialising in brush honing and polishing of ultra-hard materials for over 70 years. The company’s machines use special brushes – nylon for basic parts or natural fibres with diamond paste for complex shapes – to polish surfaces and create consistent edge radii. With planetary polishing tables, the machines deburr, polish and edge-round components on one or both sides with high precision. See the latest Gerber machines on Stand D18 in Hall 11.

FLP Microfinishing, in Hall 11 on Stand E77, is a manufacturer of high-precision fine-grinding, lapping and polishing machines. In addition to the automotive industry, the broad range of applications also includes the fields of optical, aerospace and medical engineering.

GPA Innova – DLyte machines use a patented dry electropolishing process, a non-abrasive technology that polishes metal parts without using liquid electrolytes. In a single automated step, DLyte can polish and deburr steel, stainless steel, cobalt chrome, titanium, aluminium, nickel and precious metals. Surface finishes below 0.09μm Ra are achievable with zero impact on part geometry. Dlyte is on Stand E38 in Hall 11.

Simon Backhouse from Advanced Grinding Solutions will be at EMO to meet with customers on its principals’ stands from 22 to 24 September.