Airbus A350 nose landing gear: A symbol of Starrag’s 20+ years of partnership with Liebherr-Aerospace

Smooth, precise and with perfect timing: modern landing gear works just like an eagle about to land. For the first time, Starrag presented a fully assembled nose landing gear of the Airbus A350 at the recent EMO 2025 exhibition in Hanover, Germany, representing a symbol of a close partnership with Liebherr-Aerospace that has lasted over 20 years.

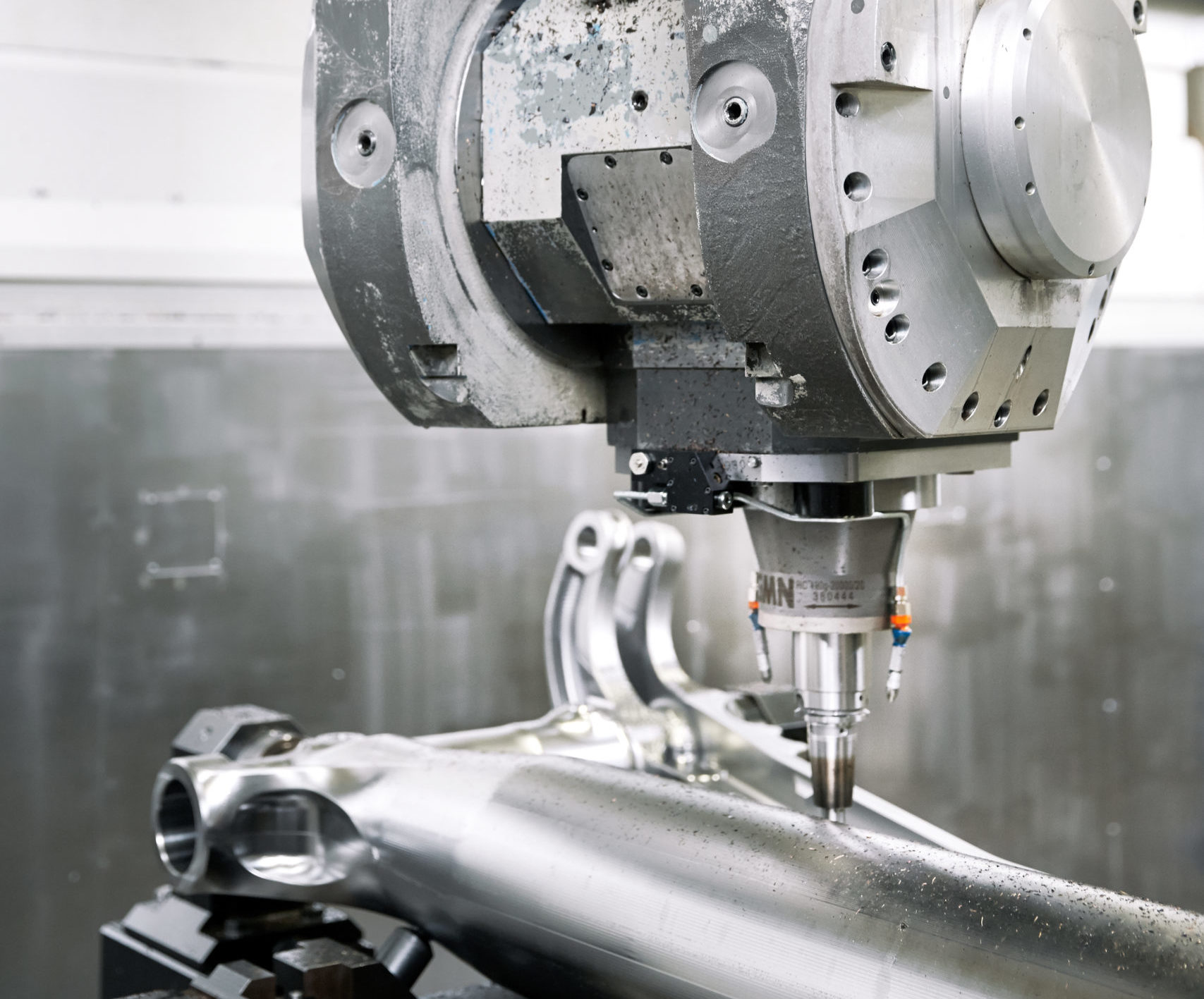

It all began in 2004 in Lindenberg, Bavaria, with a single Droop+Rein FOGS machine. Today, the partnership has developed into one of the most productive in the field of landing gear production. To celebrate, Starrag exhibited a fully assembled nose landing gear for the Airbus A350 – manufactured by Liebherr-Aerospace Lindenberg and machined on a Droop+Rein machining centre.

A landing gear partnership of equals

The partnership represents the shared journey of two global specialists – one at the system level, the other in mechanical engineering. It is a collaboration of equals based on technical understanding, long-term thinking and a global perspective.

“The trust that Liebherr-Aerospace has placed in us for two decades is both an obligation and an incentive for us,” emphasises Heiko Quack, Director of Sales for Large Projects. “Together, we’ve developed processes that are considered a global benchmark – especially when it comes to safety-critical components.”

For over 20 years, the two companies have been working closely together to produce one of the most demanding components in the aviation industry efficiently, reliably and with maximum vertical integration – landing gear. Starrag supplies the machining technology; Liebherr the system solution.

Liebherr-Aerospace operates one of the most modern landing gear production sites in Europe at its Lindenberg site, where four Droop+Rein FOGS machining centres work in combination. This capability is supplemented by robot-supported tool systems, laser measurement and integrated automation. The decision to purchase the first Droop+Rein FOGS machine was made back in 2004 because its concept – originally developed for tool and mould making – was ideally suited to the complex outer contours and tolerance requirements of landing gear parts.

The philosophy: As many work steps as possible in one clamping operation

Nose landing gear

The nose landing gear is smaller than the main landing gear but plays a key role. It enables directional changes when taxiing, absorbs high impact forces when touching down and functions under all climatic conditions. The system was redesigned for the A350-1000 long version with a take-off weight of 308 tonnes. Liebherr was able to draw on its decades of experience to do so.

These kinds of sophisticated systems are no longer solely produced in-house, but in a global production network. In addition to the four Droop+Rein machines in Lindenberg, nine more machines were installed across Europe and Asia. This investment was made possible through close technological co-operation with Starrag. The Bielefeld-produced machines not only provide the necessary precision, but also the basis for a globally standardised production approach – tailored to the requirements of safety-critical components and their highly repeatable accuracy.

Reliability right from the start

“Since the first machine installations, we’ve been working with a contractually guaranteed availability of over 95%,” highlights Quack. “This reliability is an important prerequisite for stable series production processes and therefore for ensuring the trust of our partners.”

The concept also applies to the machining centres installed at the very beginning – they are still in use today and continue to achieve the same high level of availability.