Added Value in Mould Making

To maintain a competitive edge in die and mould making, Krämer+Grebe GmbH & Co. KG emphasizes efficient production and high process reliability. With a history spanning over a century, Krämer+Grebe has continuously evolved. The company, founded in the early 20th century, initially focused on classic model assembly. Over the years, machine engineering became more significant, leading to the production of foundry machines and meat-processing equipment.

In the 1980s, Krämer+Grebe sold its machine engineering division to refocus on model assembly. This shift eventually led to the company’s current specialization in die and mould making, primarily serving the automotive industry. Their clientele includes major car manufacturers, suppliers, and foundries. Embracing globalization, Krämer+Grebe established an international presence to support their global clients.

From Handicraft to Industrial Precision

Under the leadership of Katrin Grebe, the founder’s great-granddaughter, since 2000, the company has accelerated its transformation, driven by technological advancements and market demands. Krämer+Grebe has transitioned from a handicraft business to an industrial entity, boasting state-of-the-art machinery, including 16 machining centers, a deep-drilling tool, lathes, discharge machines, and 3D printing capabilities. The production staff operates in an 11,000 square meter manufacturing space.

The company excels in solving complex geometries and meeting stringent casting requirements. Their product portfolio includes models related to the motor and power train, core boxes, handling devices, gauges, and low-pressure moulds. Krämer+Grebe has also produced pressure die cast moulds for lightweight designs and is actively participating in the transition to electric mobility. Currently, 20% of their revenue comes from parts for electric vehicles, with a focus on power train components like the stator housing for electric motors.

Embracing Industry 4.0 and Digitalization

To remain economical in a competitive environment, Krämer+Grebe has redesigned its manufacturing processes in line with Industry 4.0 principles, fully digitalizing their workflow. The in-house R&D department plays a crucial role, collaborating with manufacturers to develop parts. Krämer+Grebe is shifting its focus towards service, offering clients added value through simulations of tools, wear and tear analysis, series production, and cooling. “We have also broadened our service and maintenance activities. Our teams are now available to our clients more or less around the clock,” says Sebastian Schneider, Head of Order Centre and Production.

MAPAL has played a pivotal role in Krämer+Grebe’s process optimization efforts over the past five years. The collaboration began with the supply of reamers from MAPAL’s Multi-Bladed Reamer Centre of Competence. MAPAL was the only manufacturer capable of producing the required high-quality tools up to 600 mm long and delivering them on time. These reamers were crucial for inserting heating cartridges in low-pressure moulds, and MAPAL’s application engineers provided on-site training and process commissioning, ensuring smooth operations.

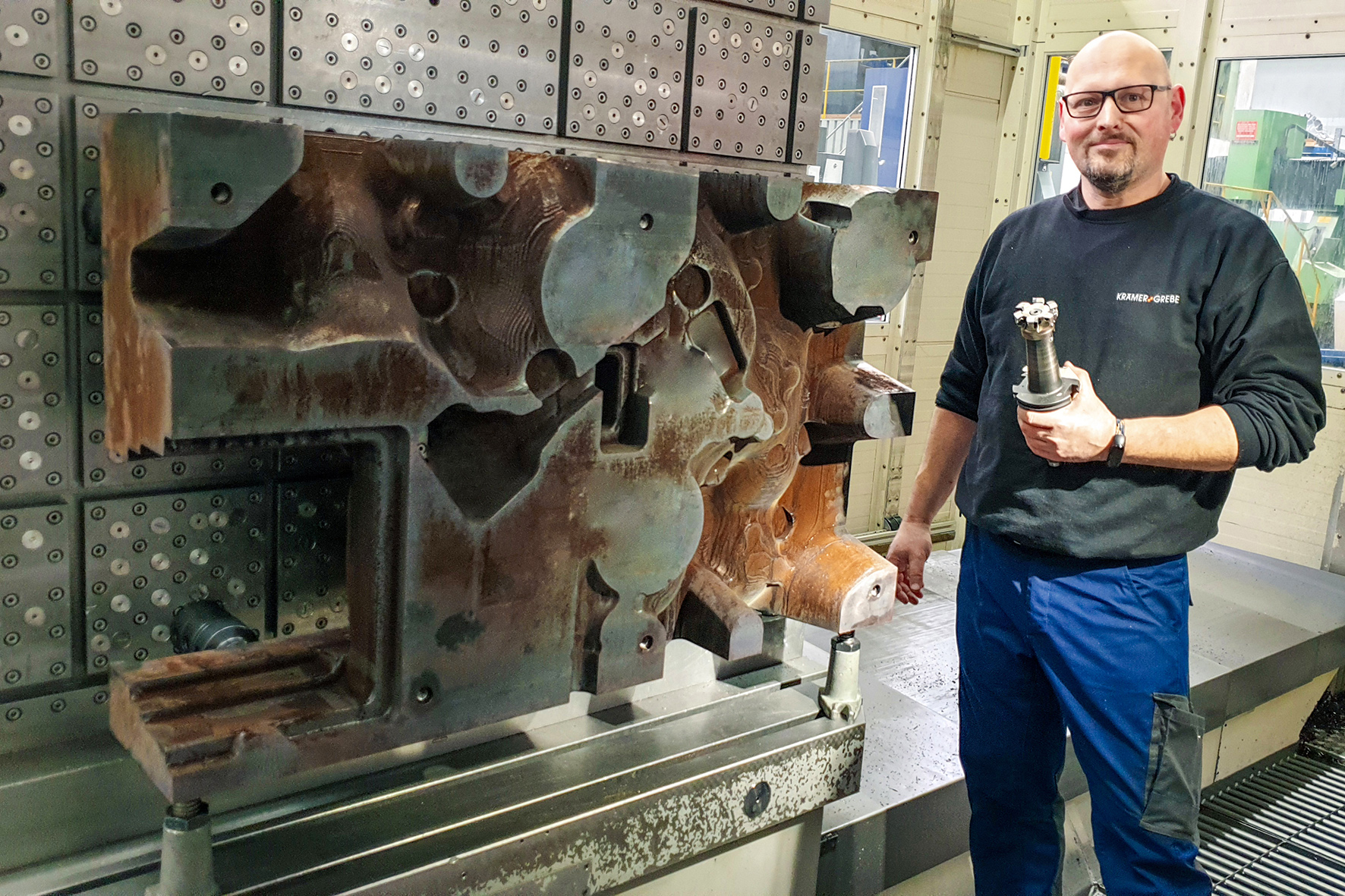

Krämer+Grebe’s process optimization also involved reevaluating their tool suppliers. Dominik Gessner, Mechanical Manufacturing Process Optimiser, highlights the importance of a collaborative partnership and application engineering over tool price. “I don’t just want a tool, I also want added value that I can apply to my processes,” Gessner asserts. This philosophy led to a closer partnership with MAPAL, especially when it came to improving processes with high-feed milling cutters.

Krämer+Grebe uses high-feed cutting for pre-roughing parts before heat treatment. They tested various high-feed milling cutters under realistic conditions, and MAPAL’s NeoMill-4-HiFeed-90 stood out. This indexable insert milling cutter achieved the highest material removal rate and longest tool life, showing uniform wear on the cutting edges. “We found out that you can easily operate the machine for an hour and a half unmanned with MAPAL. This offers us the big advantage that staff can be deployed at another machine during this time,” Schneider explains. Consequently, MAPAL became their preferred choice for high-feed milling cutters.

Strategic Partnerships for Continuous Improvement

Uwe Rein, Business Development Manager Die & Mould at MAPAL, emphasizes the importance of reducing lead times in die and mould making. “Companies that make dies and moulds don’t have a lot of leeway nowadays to reduce their lead time. However, this is precisely the deciding factor as to whether a company makes money or not. That’s why every opportunity to increase productivity must be grasped.” Schneider agrees, noting that in individual part manufacturing, the right strategy, parameters, and tools are crucial from the start.

Krämer+Grebe’s focus on partners that offer good application engineering and CAM support aligns with their goal of continuous improvement. “We want to work with as few steady partners as possible. MAPAL is one of them,” Schneider states. For MAPAL, die and mould making is a relatively new segment. They have previously focused on precise and efficient machining of pre-cast parts but are now getting involved earlier in the process to ensure optimal mould production. “It is very interesting to be on board from the very start,” Rein asserts. Both companies have learned and improved through their collaboration, enhancing the design of new parts.

In conclusion, Krämer+Grebe’s commitment to efficient production, process reliability, and strategic partnerships has enabled them to remain competitive in the die and mould making industry. By embracing digitalization and Industry 4.0 principles, the company continues to innovate and add value for their clients, ensuring their position as a leader in the field.