A&D achieve the ‘Apex’ of Precision

Since the relatively recent launch of the CRYSTA-Apex V Series of Coordinate Measuring Machines (CMMs), the precision, speed and flexibility delivered by the innovative Mitutoyo CNC CMMs has ensured high levels of sales across a wide range of UK industries, not least within the country’s subcontracting sector. One such busy subcontractor now reaping the benefits of using a CRYSTA-Apex V Series CMM is Glenrothes, Fife based A & D Precision Engineering Ltd.

Much of A&D’s success is based on the business regarding quality and efficiency as being one and the same thing, these values are reflected in the company’s use of highly efficient CNC machine tools. The use of advanced 5 Axis Milling allows the machining of complex multi-sided parts with improved accuracy and reduced setup times. Whilst CNC Turning with a Y-axis and Live Tooling allows the highly efficient turning and complete machining of parts that previously required separate milling operations.

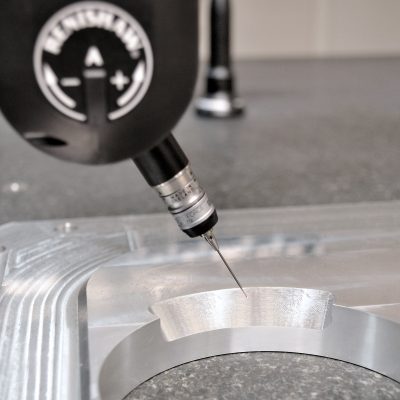

Further ensuring enhanced quality and efficiency standards, A&D employ a variety of advanced Mitutoyo quality control equipment, including laser-scan micrometers, a Crysta Apex/Ko-Ga-Me shop floor CMM and a non-contact Quick Vision measuring system. The latest addition to A&D’s Mitutoyo quality control aids is the company’s recently installed CRYSTA-Apex V Series CMM fitted with a Renishaw RTP20 motorised head with a TP20 touch-trigger probe.

Explaining the reason for the CMMs purchase A&D Managing Director, John Trolland said. “In addition to employing highly skilled staff that uphold our standards we also invest in high-precision quality control equipment. As Mitutoyo products provide the accuracy and speed of use we require, and have also proven to be extremely reliable, over many years we have remained loyal to the brand. In addition, it helps that we also receive an excellent service from the company.

“Having recently secured a long-term contract for the production of large, complex components with demanding specifications, from a multi-national corporation, we needed a high-precision CMM with a capacity greater than that of our existing machine. After studying the impressive specification and the many new features included in the new CRYSTA-Apex V Series, as a previous user of Mitutoyo CMMs I was able to appreciate the technical leap forward, in terms of precision, speed, ease of use and flexibility, that the new CNC CMMs provide. Therefore, we were happy to place an order.

“Any bottlenecks in inspection can delay the delivery of components, therefore as well as our advanced new CMM solving our inspection capacity problem and further improving our already excellent precision measuring capabilities, its impressive speed has significantly improved the throughput of parts in our busy Quality Control department. Now, in addition to accurately inspecting single large components, our staff are able to load large batches of smaller parts onto the new machine’s granite bed and start rapid, fully automated CNC inspection routines. On completion, we are able to archive all inspection results and if required generate detailed inspection reports.

“The rapid action of our new CRYSTA-Apex V CMM allows our quality personnel to provide quicker feed-back, related to situations such as component features that are drifting towards out of tolerance conditions, to our production staff. Also, as our new CMM can perform an increased number of inspection routine each day it will be able to keep-pace with all anticipated increases in production.

“Our purchasing decision was further influenced by the fact that the new Mitutoyo CMMs feature advanced SMS technology. Although we aren’t currently using this facility, when we begin to link our various in-house systems, we anticipate making full use of this advanced Mitutoyo communication system.”

Since its launch, the accuracy, speed and versatility of the CRYSTA-Apex V series of CMMs has resulted in record numbers of global sales. With a line-up of ten models covering the measurements of small to mid-sized workpieces, the cutting-edge CMMs are able to accommodate the majority of parts. In addition to standard tactile probes the new machines offer multi-sensor flexibility, if required, all models can be specified with vision, laser, surface-finish and scanning probe technologies. The A&D CRYSTA-Apex V series CMM was supplied fitted with an advanced Renishaw RTP20 motorised head with an integral TP20 touch-trigger probe, providing improved productivity, increased reach and greater flexibility.

As the successor to the popular Mitutoyo CRYSTA-Apex S range, the new CMMs build on their predecessors’ success and are able to perform very accurate measurements at high speed. In addition to use in quality departments, as the CRYSTA-Apex V series machines have a high resistance to environmental conditions, they are equally suitable for use on the shopfloor.

Given the advent of Smart Factories and the increasing use of The Internet of Things (IoT), CRYSTA-Apex V CMMs are equipped with Mitutoyo’s recently introduced Smart Measuring System (SMS) technology. Proving extremely popular with many early users, SMS allows the online monitoring of each CMMs’ operational status and the capture of records related to key parts. Although at present SMS is not relative to some customers, given the renowned longevity of Mitutoyo CMMs, if users wish to embrace the IoT at a later time, future proof CRYSTA-Apex V CMMs will be able to seamlessly integrate into all new advanced communication systems.