A Week of innovation and technology – EMO 2025

EMO 2025 did not disappoint, in fact the 50th anniversary edition proved to be an electrifying showcase of technology and innovation.

The Machinery and Manufacturing team spent a week in Germany exploring the Hannover halls, witnessing firsthand how the industry is redefining productivity, sustainability, and flexibility. From cutting-edge machining solutions to intelligent automation and sustainable practices, the long-awaited event highlighted the technologies shaping the future of manufacturing.

Machining & Tooling Innovations

High-mix, low-volume production drew attention with Mazak’s INTEGREX j-Series NEO multi-tasking machines. The j-200 NEO and j-200S NEO combined powerful spindles, increased bar capacity, and expanded tool magazines with automation compatibility, while inverter-driven hydraulics and chillers underlined a strong sustainability focus.

DMG MORI’s expansive display of over 40 high-technology production centres, including eight world premieres and 33 automated manufacturing solutions, demonstrated how integrated production and digitalisation are shaping modern manufacturing workflows.

ISCAR’s bold message, “You Machining Intelligently?”, introduced new grades, coatings, and geometries designed to boost productivity and extend tool life, alongside multifunction tools for complete machining on CNC mill-turn centres. The stand reinforced that intelligent machining combines speed, precision, and sustainability.

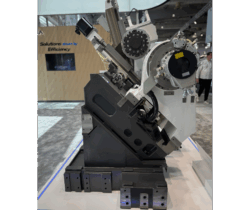

Grinding and finishing technology impressed with machines capable of handling both complex and high-volume tasks. Fritz Studer presented a universal cylindrical grinding machine, alongside the versatile S31 with insertLoad, the all-round S41, the cost-effective favoritCNC, and the internal and radius-focused S131 Radius. Live demonstrations highlighted accuracy, performance, and software integration across the range.

Okuma created a “wow moment” with the debut of the MB-100 3-axis VMC, featuring a massive 2m x 1m bed in a world-exclusive unveiling. Visitors admired the engineering quality of the solid, slanted cast base, manufactured in Okuma’s Japanese foundry to optimise rigidity and performance. Mill-turn machines, including the new M70 and M20 with automation towers, drew attention with live machining demonstrations, showing practical integration of robotics and production workflows.

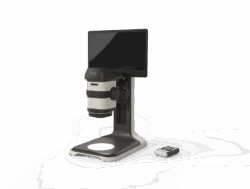

Sunnen unveiled a new Beckhoff-based control interface for honing and deep-hole drilling, providing easier setup and better process consistency, emphasising how modern control systems can improve both productivity and precision.

Another highlight came from Sodick, presenting the ALC600G high-precision wire-cut EDM machine with a 6-axis SDG robot developed in collaboration with Fruitcore Robotics | ProOne. The combination highlighted efficiency, precision, and process reliability, showing how EDM technology can integrate with intelligent automation for fully future-ready production.

Sustainability remained a theme across the exhibition, from Mitsubishi Materials’ Circular Economy Area, highlighting advanced carbide substrates, coatings, PCBN tools, and the MV series inserts, to ZTT’s elite Pangu range with durable coatings and substrates. Jason Purcell, UK MD of Mitsubishi Materials, explained: “We’re evolving from simply supplying tools to offering complete solutions, from design to aftersales support.”

MA Ford extended its 278 Series 5-flute aluminium tools with thin-wall finishers and new roughers optimised for aerospace and automotive applications, while VOLLMER combined grinding, erosion, and laser technology on its stand. The VGrind infinity linear demonstrated precision and flexibility, the VLaser 370 stability on ultra-hard materials, and the VHybrid 260 grinding and erosion for microtools as small as 0.45 mm. The Smart Hub platform provided IoT-driven insights, while subsidiaries Loroch and ultraTEC presented the KSC 560-B sharpening machine, TC 720 measuring device, and A20C ultrasonic deburring system.

MAPAL celebrated its 75th anniversary with innovations including the OptiMill-Uni-HPC cutter, HPR400 reaming system, and aluminium machining solutions under the theme “Empower Your Aluminium Machining.” Where precision toolholding was highlighted by Nikken’s Zero-Fit tool holders, capable of sub-5µm run-out accuracy.

Energy efficiency and workplace safety were emphasised with intelligent extraction systems. Filtermist’s F Save smart hub automatically switched off mist collectors when machines were idle, saving up to 80% of energy with rapid ROI. The new AW filter unit, co-developed with Absolent AB, captured submicron particles from neat oils, protecting workers while maintaining performance. René Joppi, Filtermist MD, said: “By only running units when needed, we reduce costs, save energy, and protect operators.”