A stereo digital microscope: from vision to reality

Every so often a new technology arrives with genuine potential to disrupt the market. For several years quality control professionals have been putting stereo microscopes to good use and, in more recent years, adopting digital microscopes (which swap a conventional magnifying lens for a camera). While the latter bring added capabilities such as image capture, data collection and traceability, the user has to settle for a flat 2D image. The only way to gauge depth is to measure the height of different features or shadows.

“For some tasks a 2D image is fine, but many others require a true stereo image,” explains Logan Wheeler, North UK Sales Manager at Vision Engineering. “Most people with two good eyes see a stereo image in normal life. We have left and right eye paths, and our brain puts the images together to give depth perception. The DRV-Z1, as the industry’s first 3D digital microscope, replicates this process.”

Vision Engineering showcased its DRV-Z1 at the recent MACH 2024 exhibition in Birmingham, where it caused quite a stir. DRV stands for Deep Reality Viewer. This is optical inspection like nothing before.

Float an idea

“In essence, our DRV-Z1 houses two digital microscopes and a pair of monitors,” he says. “These two high-resolution channels project two distinct optical paths through two specialist lenses on to a unique, large convex mirror, giving crisp 3D visualisation in stereo. When users sit down in front of the microscope they see a full 3D HD [1080p] digital image float before their eyes. There’s no hunching over and squinting down an eyepiece.”

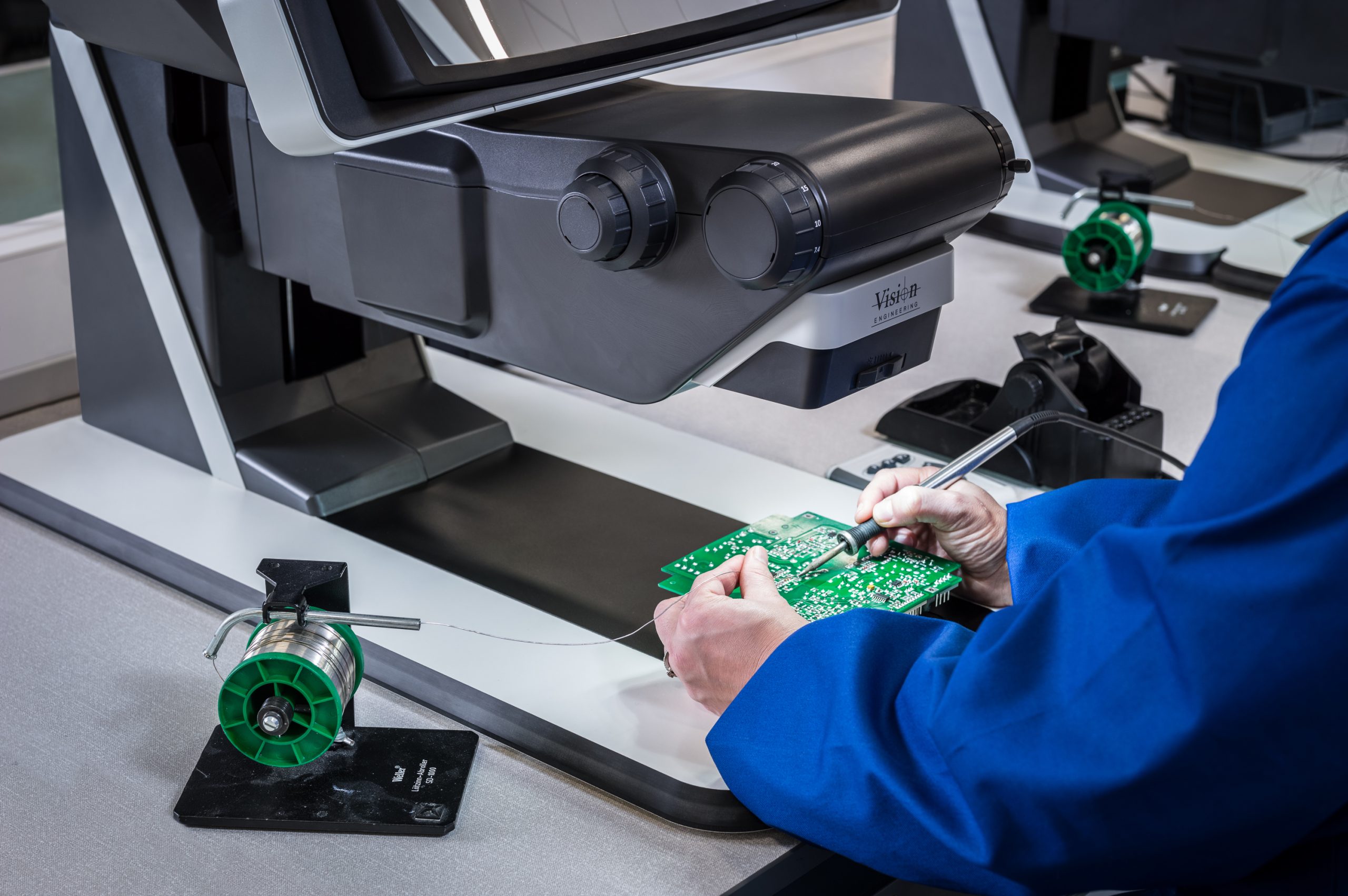

Users of the DRV-Z1 do not require any special eyewear or goggles, and there are no unpleasant side effects. They simply sit back and view high-definition 3D images, with impressive depth perception, as easily as real life. This ergonomic design improves comfort, efficiency and productivity by enabling good posture and reducing fatigue. Operators enjoy freedom of head movement, a natural view of the object and easy hand-eye co-ordination for precision inspection tasks, including rework and repair. In addition, there are no limitations for wearers of prescription or safety glasses.

The experience is not dissimilar to using a virtual reality (VR) headset, but without the user disadvantages of strapping a unit to their head, and without getting tired eyes or a sense of isolation and dizziness.

Vision Engineering’s patented DRV technology aids visual inspection at a host of manufacturing businesses, including those making aerospace and automotive components. Medical device manufacturers, PCB manufacturers and companies producing additive parts/prototypes also benefit. Indeed, the list of applications already extends to fields as diverse as geospatial and ophthalmology.

Ahead of its time

“A key advantage of DRV is real-time collaboration on a global scale,” says Mr Wheeler. “Users can share 3D HD images across networks to other DRV-Z1 systems for simultaneous remote viewing at 60 frames a second.”

With this capability, colleagues can view anything from sensitive objects in strictly controlled environments through to prototypes created thousands of miles away, without ever leaving the office. The result? Big savings in time and cost, along with reductions in carbon emissions.

Magnifications of between 6.1x – 93x (additional 2x digital) with zoom capabilities are possible, depending on the selected objective lens (three are available). Users of the DRV-Z1 will also discover a very large working distance of up to 182 mm, allowing them to use tools such as screwdrivers, glue guns and soldering irons while inspecting the process at high resolution. Notably, an integral aperture (iris) allows operators to adjust or increase depth of field at higher magnifications.

The big picture

“Image capture is another inherent part of the system,” reveals Mr Wheeler. “By simply plugging in a USB drive, the user can capture whatever they see on the screen as a jpg format image.”

Although Vision Engineering classes the DRV-Z1 as an inspection system rather than a metrology system, various dimensioning software solutions with different capability levels, such as ViPlus and DimensionOne, are available to provide component measurement.

Ultimately, this glasses-free 3D experience with true depth perception, extra wide field of view, HD resolution and excellent subject clarity make the DRV-Z1 an astute choice for inspection applications which would otherwise be problematic using conventional technology. The system is already completely changing the way manufacturers view, capture and share 3D images of objects. This particular vision has become a reality.