A new chapter in machine safety

At the end of 2024 the revised ISO 13855 standard for the positioning of protective devices on machinery was published. It replaces the 2010 edition and sets a new benchmark for safeguarding in an industry transformed over the last 15 years. Flexible production, mobile robots and new human machine interaction concepts are now commonplace, and the updated standard ensures safety technology keeps pace.

For Markus Erdorf, Senior Safety Consultant at Leuze, the update was overdue: “The last valid version was published in 2010 which is a long time in industrial automation. “Today we’re dealing with more flexible production systems, more mobile robots and new operating concepts. The previous standard could only reflect this to a limited extent. We also looked at the incidence of accidents at work and derived normative consequences from this.”

Markus says ISO 13855:2024 is better aligned with the current state of the art because it provides more precise specifications for calculating safety distances and positioning protective devices. It also introduces previously absent topics.

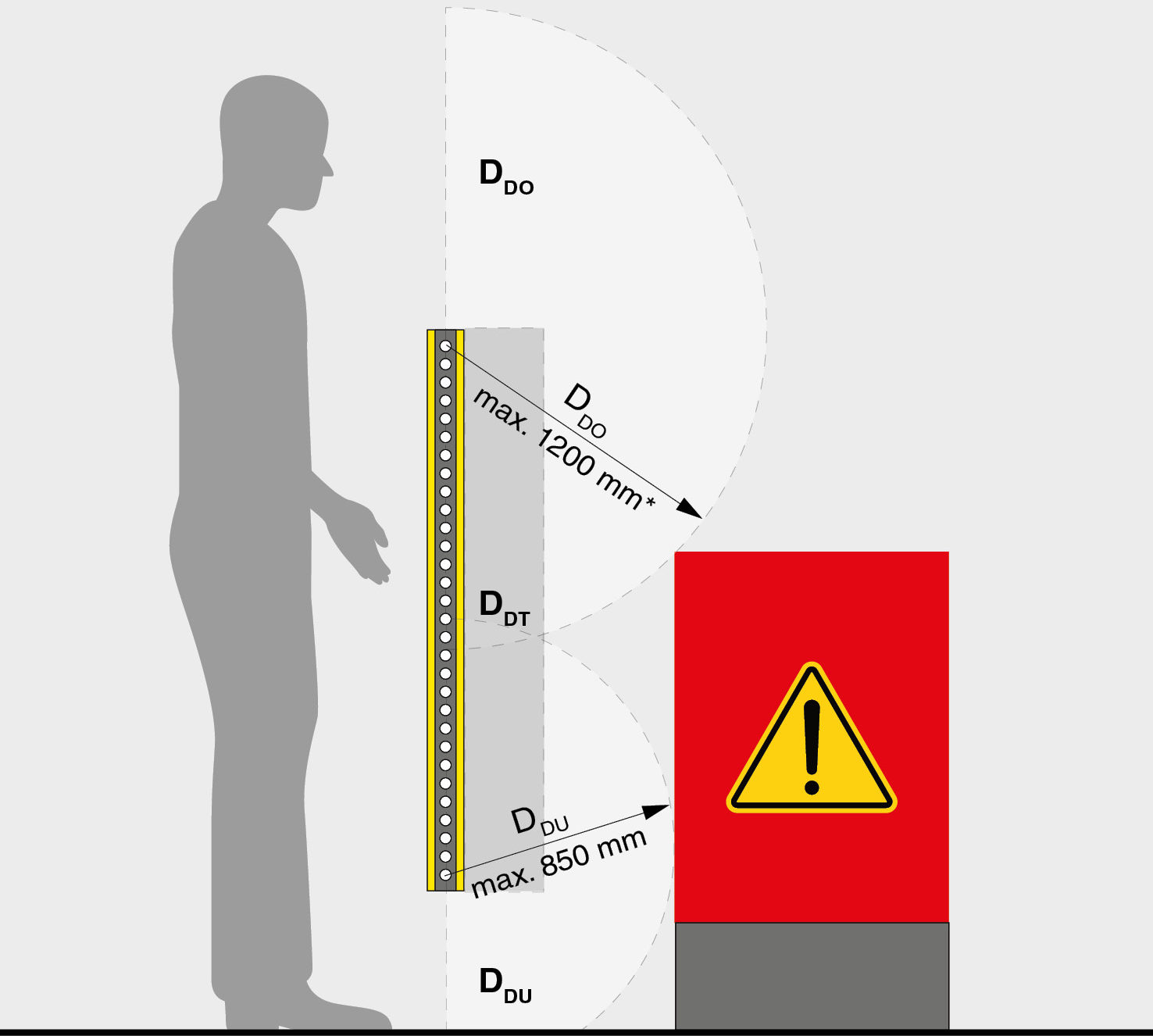

A central change concerns safety distance. For a right angled approach it must now be calculated based on reaching over, reaching through and reaching under the protective field. The reaching under factor is new and prevents operators bypassing protective fields.

“The component for reaching under did not exist before and the component for reaching through has been expanded by a formula,” explains Markus. “For the parallel approach of a person the calculation has been simplified because flat rate values now apply. The Z supplements which result for example from scanner measurement inaccuracy or vehicle brake wear have now been included.”

The standard also clarifies the positioning of safety related manual control devices such as acknowledgement buttons. Previously guidance stated only that a reset device must not be accessible from the danger zone. Now the distance must be calculated, ending much of the past debate about accessibility.

ISO 13855:2024 also introduces the concept of dynamic safety distance, allowing protective distances to adapt depending on robot speed, braking distance or movement direction.

“It becomes more accurate but also more complex,” says Markus. “It means more responsibility for the users of the standard.”

The update will be most visible in vertical safety light grids. Two beam light grids previously permitted with justification are now effectively ruled out. Beam spacing is limited to 400 mm to prevent climbing through and the minimum height for the lowest beam has been reduced from 300 to 200 mm to prevent creeping under. The 900 mm value to prevent climbing over remains unchanged, meaning at least three beams are now required in most applications.

“Manufacturers and operators must take this into account when selecting the required safety technology,” says Markus. “We offer suitable solutions with our multiple light beam safety devices in up to four beam versions.”

The update also clarifies safety distance where steps, platforms or level differences exist. Previously there was uncertainty over which surface should be treated as the reference plane. The new standard provides explicit rules and examples which consider ascent, descent, step height and width.

Whether existing systems need modification depends on whether the organisation is a manufacturer or an operator. Manufacturers must meet the state-of-the-art at the time a machine is placed on the market, so newly built machines should comply with ISO 13855:2024. Operators must follow UK industrial safety regulations and update safeguards where the state of the art has changed.

“The new version of the standard is state of the art and therefore also relevant for existing systems.”

Keeping up with evolving standards remains challenging. Leuze supports manufacturers and operators through safety inspections, follow up time measurements, complete safety assessments and turnkey safeguarding projects. The company runs practical online seminars on ISO 13855:2024 and provides calculation tools online. For complex applications the Leuze Sensor People team offers bespoke consulting on sensor selection and safety solutions.

“Sustainable machine safety begins with the professional planning of safety systems and extends over the entire lifecycle of a machine,” concludes Markus. “The new standard provides the foundation. Now the industry has to apply it properly.”